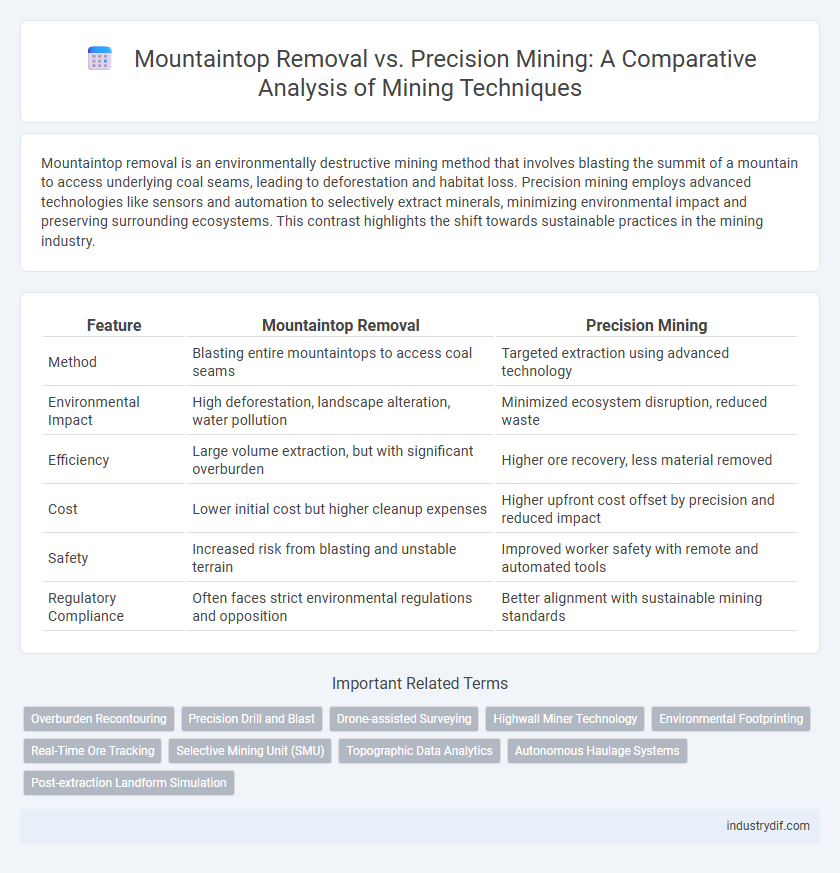

Mountaintop removal is an environmentally destructive mining method that involves blasting the summit of a mountain to access underlying coal seams, leading to deforestation and habitat loss. Precision mining employs advanced technologies like sensors and automation to selectively extract minerals, minimizing environmental impact and preserving surrounding ecosystems. This contrast highlights the shift towards sustainable practices in the mining industry.

Table of Comparison

| Feature | Mountaintop Removal | Precision Mining |

|---|---|---|

| Method | Blasting entire mountaintops to access coal seams | Targeted extraction using advanced technology |

| Environmental Impact | High deforestation, landscape alteration, water pollution | Minimized ecosystem disruption, reduced waste |

| Efficiency | Large volume extraction, but with significant overburden | Higher ore recovery, less material removed |

| Cost | Lower initial cost but higher cleanup expenses | Higher upfront cost offset by precision and reduced impact |

| Safety | Increased risk from blasting and unstable terrain | Improved worker safety with remote and automated tools |

| Regulatory Compliance | Often faces strict environmental regulations and opposition | Better alignment with sustainable mining standards |

Introduction to Mountaintop Removal and Precision Mining

Mountaintop removal is a large-scale mining method that involves blasting away the summit of a mountain to expose coal seams underneath, resulting in significant landscape alteration and environmental impact. Precision mining uses advanced technologies such as GPS, drones, and automated machinery to extract minerals with minimal environmental disturbance and greater resource efficiency. This method enhances operational accuracy, reduces waste, and promotes sustainable mining practices compared to traditional mountaintop removal.

Historical Development of Mining Techniques

Mountaintop removal mining emerged in the 1970s as a highly disruptive technique primarily used in Appalachian coal extraction, radically altering landscapes and ecosystems. Precision mining, evolving from advancements in geospatial technologies and automation since the early 2000s, emphasizes minimizing environmental impact while maximizing resource recovery through targeted excavation. The transition from broad-scale removal to data-driven precision reflects an ongoing shift toward sustainable mining practices driven by regulatory pressures and technological innovation.

Defining Mountaintop Removal Mining

Mountaintop removal mining involves the large-scale blasting and removal of entire mountain summits to access underlying coal seams, leading to significant landscape alteration and ecosystem disruption. This technique contrasts sharply with precision mining, which targets coal deposits using controlled, minimal-impact methods to reduce environmental damage. The extensive deforestation and alteration of terrain caused by mountaintop removal contribute to soil erosion, water contamination, and habitat destruction in affected mining regions.

Outline of Precision Mining Methods

Precision mining methods employ advanced technologies such as 3D geological modeling, drone surveys, and real-time sensor data to target mineral deposits with minimal environmental impact. Techniques like blast optimization and autonomous drilling increase extraction efficiency while reducing waste and ecosystem disruption compared to mountaintop removal. The integration of remote sensing, machine learning, and geospatial analysis enables precise resource identification and extraction, promoting sustainable mining operations.

Environmental Impacts: A Comparative Analysis

Mountaintop removal mining causes extensive deforestation, habitat destruction, and water pollution due to the displacement of entire mountaintops, leading to long-term ecological damage. Precision mining employs advanced technologies such as drones and geospatial mapping to minimize land disturbance and reduce toxic runoff, offering a more sustainable alternative. Comparative analyses reveal that precision mining significantly lowers soil erosion and biodiversity loss compared to the widespread environmental degradation associated with mountaintop removal.

Economic Factors in Both Mining Approaches

Mountaintop removal mining offers cost advantages through large-scale coal extraction and reduced labor expenses but often incurs high expenses from environmental remediation and regulatory compliance. Precision mining, while involving higher initial investments in advanced technologies and skilled labor, can increase operational efficiency and resource recovery, leading to potentially higher long-term profitability. Economic feasibility in both methods depends on balancing upfront costs against the value of extracted resources and post-mining land use obligations.

Safety and Workforce Considerations

Mountaintop removal mining poses significant safety risks due to unstable terrain and exposure to hazardous dust and debris, leading to higher incidences of accidents and respiratory illnesses among workers. Precision mining employs advanced technology such as drones, sensors, and automation to enhance worker safety by reducing direct exposure to dangerous environments and improving monitoring of hazardous conditions. Workforce considerations in precision mining include retraining for technical skills and job shifts from manual labor to equipment operation, promoting a safer and more sustainable mining industry.

Technological Innovations Driving Precision Mining

Technological innovations driving precision mining include advanced remote sensing, real-time data analytics, and automated drilling systems that enable targeted extraction with minimal environmental impact. High-resolution LiDAR and satellite imaging allow for detailed topographical mapping, reducing unnecessary surface disturbance compared to traditional mountaintop removal techniques. Machine learning algorithms optimize mineral recovery rates by predicting ore body locations, enhancing efficiency while preserving surrounding ecosystems.

Community and Social Implications

Mountaintop removal mining causes significant disruption to local communities by displacing residents and destroying ecosystems, leading to long-term health issues and loss of cultural heritage. Precision mining minimizes environmental damage through targeted extraction, supporting community stability and preserving biodiversity. Shifting to precision techniques fosters sustainable development and improves social outcomes by reducing pollution and maintaining local livelihoods.

Future Outlook: Trends and Regulatory Perspectives

Mountaintop removal mining faces increasing regulatory scrutiny due to its environmental impact, driving a shift towards precision mining techniques that minimize land disturbance and enhance resource recovery. Emerging technologies such as drone mapping, AI-driven ore modeling, and autonomous machinery are accelerating the adoption of precision mining, aligning with stricter environmental regulations and sustainable mining goals. Future trends indicate robust policy frameworks promoting reduced ecological footprints and incentivizing investments in advanced precision mining solutions across the industry.

Related Important Terms

Overburden Recontouring

Mountaintop removal generates significant environmental disruption through large-scale overburden removal and insufficient recontouring, leading to habitat loss and water pollution. Precision mining minimizes overburden displacement by targeting specific ore zones, enabling more effective and sustainable recontouring that preserves ecosystem stability and reduces erosion risks.

Precision Drill and Blast

Precision drill and blast techniques in mining minimize environmental impact by targeting specific ore zones, reducing waste and preserving surrounding ecosystems compared to mountaintop removal. This method enhances safety and operational efficiency through controlled explosions, optimizing resource extraction while limiting surface disruption and habitat destruction.

Drone-assisted Surveying

Drone-assisted surveying revolutionizes both mountaintop removal and precision mining by providing high-resolution topographic data that enhances site assessment accuracy and environmental impact analysis. In mountaintop removal, drones help monitor ecological disturbances, while in precision mining, they enable targeted extraction, minimizing land disruption and improving resource efficiency.

Highwall Miner Technology

Highwall Miner technology revolutionizes coal extraction by enabling precise, targeted mining along exposed coal seams, significantly reducing environmental disruption compared to traditional mountaintop removal methods. This mechanized approach minimizes land disturbance and waste generation while improving safety and operational efficiency in surface mining operations.

Environmental Footprinting

Mountaintop removal mining drastically alters ecosystems by removing entire mountaintops, leading to deforestation, habitat loss, and water pollution with heavy metals. Precision mining minimizes environmental footprint through targeted extraction techniques that reduce land disturbance and waste generation, preserving biodiversity and maintaining soil and water quality.

Real-Time Ore Tracking

Mountaintop removal mining often results in significant environmental disruption and challenges in monitoring ore quality, whereas precision mining utilizes real-time ore tracking technology to optimize extraction efficiency and minimize waste. Implementing advanced sensors and data analytics in real-time ore tracking enables precise identification and separation of valuable minerals, enhancing resource recovery while reducing ecological impact.

Selective Mining Unit (SMU)

Selective Mining Units (SMUs) in precision mining allow targeted extraction of high-grade ore, minimizing environmental disruption compared to the broad-scale land clearance in mountaintop removal. This method enhances resource efficiency and reduces ecological footprint by focusing on economically viable sections within the ore body.

Topographic Data Analytics

Topographic data analytics enhances precision mining by using detailed elevation models and spatial analysis to minimize environmental impact and optimize resource extraction compared to mountaintop removal, which often results in extensive habitat destruction and altered watershed systems. Advanced LiDAR and GIS technologies enable precise targeting of mineral deposits, reducing overburden removal and preserving surrounding topography.

Autonomous Haulage Systems

Autonomous Haulage Systems (AHS) in precision mining significantly reduce environmental impact compared to mountaintop removal by enabling targeted extraction with minimal land disruption and enhanced operational efficiency. AHS technology improves safety and productivity by using real-time data and AI-driven vehicles, thereby promoting sustainable mining practices while minimizing ecological footprint.

Post-extraction Landform Simulation

Mountaintop removal reshapes vast landscapes through extensive debris displacement, often resulting in altered watershed patterns and long-term ecological disruption, while precision mining employs digital terrain modeling and post-extraction landform simulation to minimize environmental impact and facilitate efficient land restoration. Advanced GIS and 3D modeling techniques enable precision mining to predict altered landforms accurately, optimizing reclamation strategies and promoting sustainable mining practices.

Mountaintop Removal vs Precision Mining Infographic

industrydif.com

industrydif.com