Smelting remains a traditional method in mining for extracting metals by applying high temperatures to separate metal from ore, often producing significant carbon emissions. Green hydrogen reduction offers a sustainable alternative by using hydrogen produced from renewable energy to reduce metal oxides, significantly lowering greenhouse gas emissions. This innovative process not only reduces environmental impact but also aligns with global efforts toward decarbonizing the mining industry.

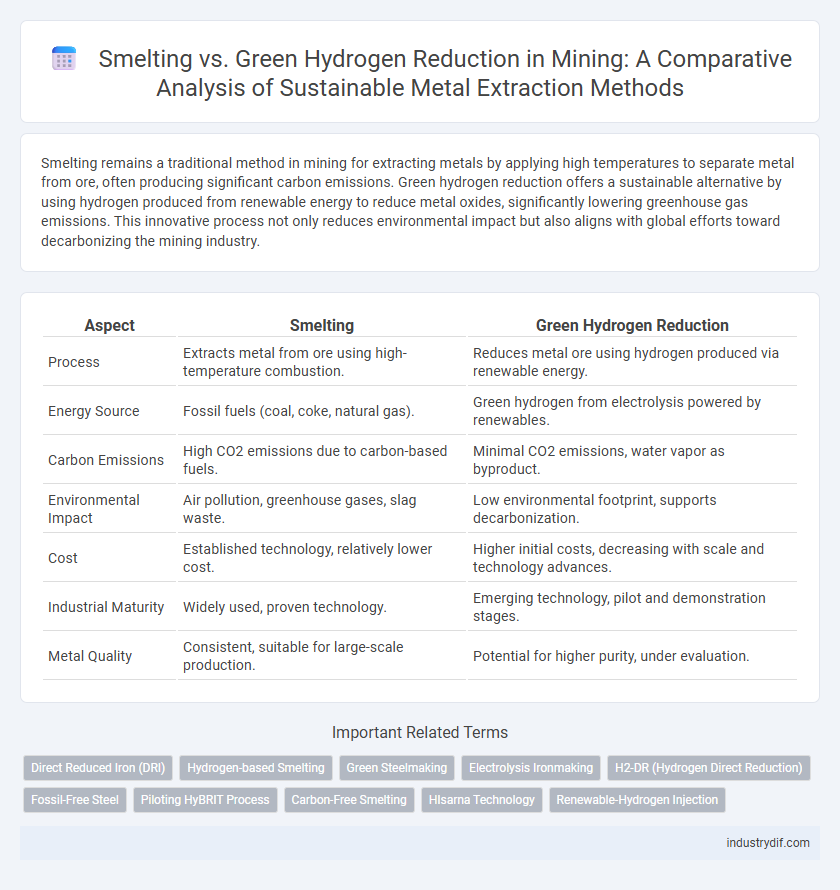

Table of Comparison

| Aspect | Smelting | Green Hydrogen Reduction |

|---|---|---|

| Process | Extracts metal from ore using high-temperature combustion. | Reduces metal ore using hydrogen produced via renewable energy. |

| Energy Source | Fossil fuels (coal, coke, natural gas). | Green hydrogen from electrolysis powered by renewables. |

| Carbon Emissions | High CO2 emissions due to carbon-based fuels. | Minimal CO2 emissions, water vapor as byproduct. |

| Environmental Impact | Air pollution, greenhouse gases, slag waste. | Low environmental footprint, supports decarbonization. |

| Cost | Established technology, relatively lower cost. | Higher initial costs, decreasing with scale and technology advances. |

| Industrial Maturity | Widely used, proven technology. | Emerging technology, pilot and demonstration stages. |

| Metal Quality | Consistent, suitable for large-scale production. | Potential for higher purity, under evaluation. |

Introduction to Metal Extraction Processes

Smelting is a traditional metal extraction process that involves heating ore to high temperatures in a furnace, causing chemical reactions that separate metal from impurities. Green hydrogen reduction offers an innovative alternative by using hydrogen produced from renewable energy sources to reduce metal oxides, significantly lowering carbon emissions. This emerging technology is gaining attention in the mining industry as a sustainable method for producing metals like steel and iron.

Overview of Traditional Smelting Methods

Traditional smelting methods in mining involve the extraction of metals from their ores through high-temperature chemical reduction using carbon-based fuels such as coke or coal. This process emits significant amounts of CO2 and other pollutants, contributing heavily to the mining sector's carbon footprint. Despite its environmental impact, smelting remains a widely used technique due to established infrastructure and efficiency in producing metals like iron and copper.

Fundamentals of Green Hydrogen Reduction

Green hydrogen reduction in mining utilizes hydrogen produced via electrolysis powered by renewable energy, significantly lowering carbon emissions compared to traditional smelting. This process involves the direct reduction of metal ores using green hydrogen gas, which reacts with metal oxides to produce pure metals and water vapor as a byproduct, eliminating CO2 release. The fundamental advantage lies in its potential to decarbonize metal production, enhance energy efficiency, and support sustainable mining operations.

Environmental Impact: Smelting vs Green Hydrogen

Smelting processes emit significant amounts of CO2 and other pollutants due to the combustion of fossil fuels, contributing heavily to global greenhouse gas emissions. Green hydrogen reduction utilizes hydrogen produced via electrolysis powered by renewable energy, resulting in near-zero carbon emissions and substantially reducing environmental impact. Transitioning from traditional smelting to green hydrogen reduction can mitigate air pollution and decrease the mining sector's carbon footprint dramatically.

Energy Efficiency Comparison in Metal Reduction

Smelting traditionally relies on carbon-intensive processes consuming significant fossil fuels, resulting in lower energy efficiency compared to green hydrogen reduction methods. Green hydrogen reduction utilizes renewable energy to produce hydrogen, which acts as a reducing agent, enabling lower overall energy consumption and reduced greenhouse gas emissions during metal extraction. This shift enhances sustainability while improving energy efficiency metrics crucial for modern mining operations.

Emissions and Carbon Footprint Analysis

Smelting processes typically emit significant amounts of CO2 and sulfur dioxide due to the combustion of fossil fuels and reduction of metal oxides with coke or coal, resulting in a high carbon footprint. Green hydrogen reduction offers a promising alternative by using hydrogen produced via renewable energy sources, which produces water vapor as the only byproduct, drastically reducing greenhouse gas emissions in metal extraction. Comparative lifecycle assessments show that transitioning to green hydrogen can lower carbon emissions in mining operations by up to 90%, aligning with global decarbonization targets.

Economic Considerations and Cost Analysis

Smelting in mining requires significant capital investment and high energy consumption, often relying on fossil fuels which incur fluctuating costs and carbon taxes. Green hydrogen reduction presents a promising alternative with potentially lower long-term operational expenses due to renewable energy use and reduced emissions penalties. However, initial infrastructure costs and hydrogen production scale currently challenge its economic feasibility compared to traditional smelting methods.

Technological Challenges and Innovations

Smelting, a traditional metallurgical process, faces significant challenges such as high carbon emissions and energy intensity, driving innovation towards greener alternatives like green hydrogen reduction. Green hydrogen reduction utilizes hydrogen produced via renewable energy sources to reduce metal oxides, minimizing CO2 emissions and presenting hurdles in hydrogen storage, scaling electrolyzers, and ensuring consistent hydrogen supply. Ongoing technological advancements focus on improving electrolyzer efficiency, integrating renewable energy systems, and developing durable materials to withstand high-temperature processes essential for industrial adoption.

Industry Adoption and Future Prospects

Smelting remains the dominant method in mining for metal extraction due to its established infrastructure and cost-effectiveness, while green hydrogen reduction is gaining traction for its potential to significantly reduce carbon emissions. Industry adoption of green hydrogen is accelerating, driven by regulatory pressures and advances in hydrogen production technology, with pilot projects demonstrating promising scalability. Future prospects suggest a gradual transition where green hydrogen reduction complements existing smelting processes, fostering a more sustainable and low-carbon mining sector.

Regulatory Trends and Sustainability Standards

Smelting processes in mining face increasing regulatory pressures to reduce carbon emissions, driven by stricter environmental standards and carbon pricing mechanisms globally. Green hydrogen reduction emerges as a sustainable alternative, supported by policies incentivizing renewable energy integration and low-carbon industrial processes. Sustainability standards like the EU's Carbon Border Adjustment Mechanism and the International Council on Mining and Metals' climate targets accelerate the shift towards green hydrogen to meet decarbonization goals.

Related Important Terms

Direct Reduced Iron (DRI)

Smelting processes for Direct Reduced Iron (DRI) rely heavily on carbon-intensive coke and coal, whereas Green Hydrogen Reduction uses renewable hydrogen, drastically reducing CO2 emissions in iron production. Green Hydrogen Reduction enhances sustainability by directly reducing iron ore with hydrogen, producing water vapor as the only byproduct, making it a critical technology for decarbonizing the mining and steel industries.

Hydrogen-based Smelting

Hydrogen-based smelting in mining leverages green hydrogen as a clean reducing agent, significantly lowering CO2 emissions compared to traditional carbon-intensive methods. This innovative process enhances metal yield and energy efficiency while aligning with global decarbonization targets in the mining and metallurgical industries.

Green Steelmaking

Green hydrogen reduction in steelmaking significantly lowers carbon emissions compared to traditional smelting, utilizing hydrogen as a clean reductant to produce green steel. This innovative process reduces reliance on fossil fuels, advancing sustainable mining and steel production while aligning with global decarbonization goals.

Electrolysis Ironmaking

Electrolysis ironmaking using green hydrogen reduction offers a sustainable alternative to traditional smelting by significantly lowering CO2 emissions through the direct reduction of iron ore with hydrogen produced via electrolysis. This method enhances energy efficiency and positions the mining sector towards achieving carbon neutrality by integrating renewable energy sources in iron production.

H2-DR (Hydrogen Direct Reduction)

Hydrogen Direct Reduction (H2-DR) offers a sustainable alternative to traditional smelting by using green hydrogen to reduce iron ore with minimal CO2 emissions, significantly lowering the carbon footprint of steel production. This technology enhances energy efficiency and aligns with global decarbonization goals by replacing carbon-intensive coke-based processes with renewable hydrogen fuel in the mining sector.

Fossil-Free Steel

Green hydrogen reduction offers a fossil-free steel production method by replacing carbon-intensive coke with clean hydrogen, significantly lowering CO2 emissions compared to traditional smelting processes. This innovative approach aligns with global decarbonization goals by utilizing renewable energy sources to produce hydrogen, enabling sustainable and environmentally responsible steel manufacturing.

Piloting HyBRIT Process

The Piloting HyBRIT process combines smelting and green hydrogen reduction to revolutionize ironmaking by drastically reducing CO2 emissions compared to traditional blast furnace methods, leveraging renewable energy and hydrogen produced via electrolysis. Experimental results from the pilot facility in Sweden demonstrate that HyBRIT can achieve near-zero fossil carbon footprints while maintaining high output quality, signaling a transformative shift in sustainable mining and metallurgical practices.

Carbon-Free Smelting

Carbon-free smelting leverages green hydrogen reduction to eliminate CO2 emissions traditionally emitted during ore processing, offering a sustainable alternative to conventional smelting methods reliant on fossil fuels. This process not only reduces the carbon footprint of metal production but also aligns with global decarbonization goals by using renewable energy sources to produce hydrogen, enabling cleaner extraction of metals like iron and copper.

HIsarna Technology

HiSarna technology revolutionizes ironmaking by directly smelting iron ore in a bath smelter, reducing energy consumption and CO2 emissions compared to traditional blast furnaces. Integrating green hydrogen reduction further cuts carbon footprint by using hydrogen as a clean reductant, enabling a more sustainable steel production pathway with reduced reliance on fossil fuels.

Renewable-Hydrogen Injection

Renewable-hydrogen injection in smelting processes reduces carbon emissions by partially replacing carbon-intensive fuels with green hydrogen, enabling lower CO2 output compared to traditional smelting. Green hydrogen reduction offers a scalable alternative by using hydrogen produced from renewable energy to directly reduce iron ore, drastically minimizing fossil fuel dependency and advancing sustainable mining operations.

Smelting vs Green Hydrogen Reduction Infographic

industrydif.com

industrydif.com