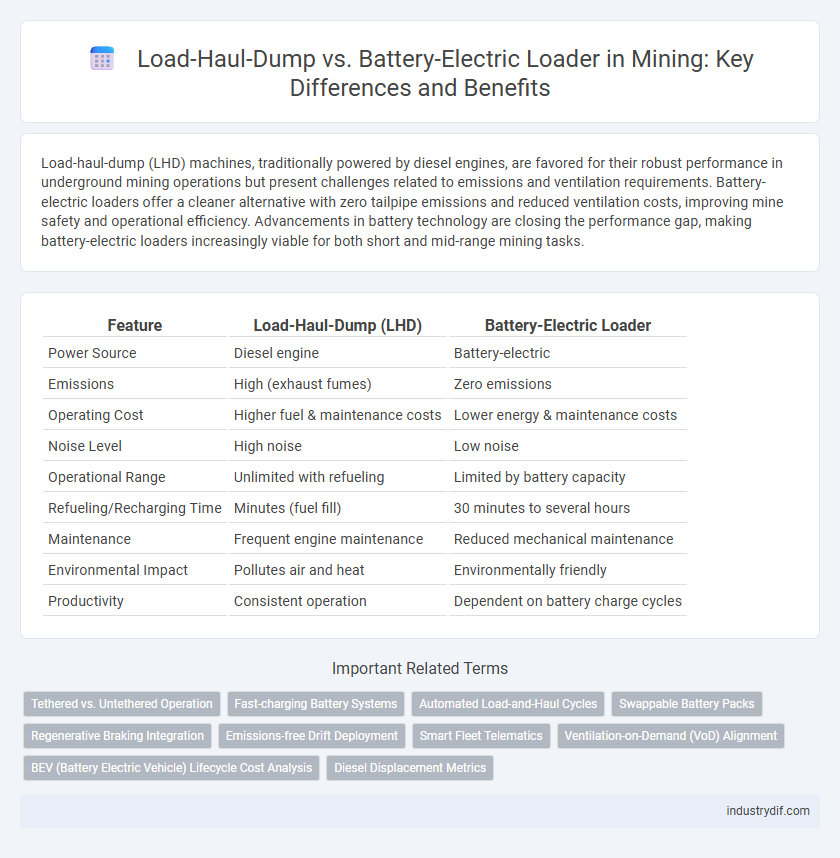

Load-haul-dump (LHD) machines, traditionally powered by diesel engines, are favored for their robust performance in underground mining operations but present challenges related to emissions and ventilation requirements. Battery-electric loaders offer a cleaner alternative with zero tailpipe emissions and reduced ventilation costs, improving mine safety and operational efficiency. Advancements in battery technology are closing the performance gap, making battery-electric loaders increasingly viable for both short and mid-range mining tasks.

Table of Comparison

| Feature | Load-Haul-Dump (LHD) | Battery-Electric Loader |

|---|---|---|

| Power Source | Diesel engine | Battery-electric |

| Emissions | High (exhaust fumes) | Zero emissions |

| Operating Cost | Higher fuel & maintenance costs | Lower energy & maintenance costs |

| Noise Level | High noise | Low noise |

| Operational Range | Unlimited with refueling | Limited by battery capacity |

| Refueling/Recharging Time | Minutes (fuel fill) | 30 minutes to several hours |

| Maintenance | Frequent engine maintenance | Reduced mechanical maintenance |

| Environmental Impact | Pollutes air and heat | Environmentally friendly |

| Productivity | Consistent operation | Dependent on battery charge cycles |

Overview of Load-Haul-Dump (LHD) Equipment

Load-haul-dump (LHD) equipment is essential in underground mining for material transport, featuring powerful diesel engines or electric motors that enable efficient loading, hauling, and dumping of ore and waste. LHDs typically range from 5 to 20 tons in payload capacity, offering robust maneuverability in confined tunnels and improved operator safety with advanced ergonomic designs. Compared to battery-electric loaders, traditional LHDs provide higher continuous runtime but face challenges with emissions and ventilation requirements underground.

Introduction to Battery-Electric Loaders

Battery-electric loaders offer a sustainable alternative to traditional load-haul-dump (LHD) machines by eliminating diesel emissions and reducing ventilation costs in underground mining operations. These loaders use advanced lithium-ion battery technology to deliver comparable productivity with lower operational noise and maintenance requirements. Adoption of battery-electric loaders supports environmental compliance and enhances worker safety through zero exhaust emissions in confined mining environments.

Performance Comparison: Traditional LHD vs. Battery-Electric

Traditional Load-Haul-Dump (LHD) machines offer reliable tunneling and ore transport performance with proven diesel powertrains optimizing fuel efficiency and torque output. Battery-electric loaders deliver superior performance in underground mining by providing instant torque, lower heat emission, and reduced ventilation requirements, enhancing operational uptime and worker safety. Comparative studies highlight battery-electric loaders achieve up to 40% lower operating costs and 20% higher productivity due to minimized maintenance and emissions control.

Energy Efficiency and Operating Costs

Load-haul-dump (LHD) machines typically consume diesel fuel, leading to higher energy costs and increased emissions compared to battery-electric loaders that use rechargeable lithium-ion batteries, resulting in significantly improved energy efficiency. Battery-electric loaders reduce operating costs by lowering fuel expenses, minimizing maintenance due to fewer moving parts, and enabling longer operational hours with rapid charging capabilities. Energy efficiency in battery-electric loaders contributes to decreased ventilation requirements in underground mines, further reducing overall operating costs and environmental impact.

Emissions and Environmental Impact

Load-haul-dump (LHD) vehicles traditionally rely on diesel engines, generating significant greenhouse gas emissions and contributing to poor underground air quality. Battery-electric loaders produce zero tailpipe emissions, drastically reducing carbon footprint and improving ventilation efficiency in mining operations. Transitioning to battery-electric loaders supports regulatory compliance with environmental standards and fosters sustainable mining practices.

Maintenance Requirements and Lifecycle

Load-haul-dump (LHD) vehicles typically demand higher maintenance due to their combustion engines, requiring frequent oil changes, filter replacements, and exhaust system upkeep, which can increase downtime and operational costs. Battery-electric loaders benefit from fewer moving parts and lack of internal combustion systems, resulting in reduced maintenance needs, lower servicing frequency, and extended lifecycle components such as electric motors and batteries. The lifecycle of battery-electric loaders often surpasses that of traditional LHDs due to decreased mechanical wear and simpler maintenance protocols, offering improved total cost of ownership and sustainability in mining operations.

Safety Considerations in Underground Mining

Load-haul-dump (LHD) machines traditionally used in underground mining pose safety risks such as diesel particulate emissions, which contribute to poor air quality and respiratory hazards. Battery-electric loaders eliminate these emissions, significantly improving workplace air quality and reducing ventilation costs while lowering the risk of fire associated with fuel storage. The quieter operation of battery-electric loaders also enhances communication and situational awareness among miners, further promoting a safer underground mining environment.

Technological Advancements in Loader Design

Load-haul-dump (LHD) machines have traditionally relied on diesel power, but recent technological advancements have integrated battery-electric loaders to reduce emissions and improve energy efficiency in underground mining. Battery-electric loaders offer enhanced maneuverability, quieter operation, and lower heat generation compared to conventional LHDs, contributing to safer, more sustainable mining environments. Innovations in battery technology, such as increased energy density and rapid charging, are accelerating the adoption of electric loaders across global mining operations.

Deployment Challenges and Adoption Rates

Load-haul-dump (LHD) machines face deployment challenges primarily due to their dependence on diesel fuel, leading to higher ventilation requirements and increased operational costs in underground mines. In contrast, battery-electric loaders offer reduced emissions and lower ventilation needs, but their adoption is hindered by limitations in battery life, charging infrastructure, and initial capital expenditure. Adoption rates for battery-electric loaders are increasing steadily, driven by regulatory pressure and sustainability goals, while LHDs remain dominant due to established technology and reliability.

Future Trends in Mining Loader Technology

Future trends in mining loader technology emphasize increased adoption of battery-electric loaders due to their zero-emission operation and lower operating costs, aligning with global sustainability goals. Load-haul-dump (LHD) machines continue to evolve with improved automation and safety features, yet battery-electric models offer enhanced energy efficiency and reduced ventilation requirements in underground mining. Advancements in battery technology and modular designs are driving the transition from traditional diesel LHDs to cleaner, more efficient electric loaders in the mining industry.

Related Important Terms

Tethered vs. Untethered Operation

Load-haul-dump (LHD) machines typically use tethered electric power cables that limit mobility but ensure continuous energy supply in mining operations, whereas battery-electric loaders operate untethered, offering enhanced flexibility and reduced cable management but requiring periodic battery recharging or swapping. The choice between tethered LHDs and untethered battery-electric loaders hinges on factors like mine size, operational range, and the balance between continuous operation and autonomous movement.

Fast-charging Battery Systems

Load-haul-dump (LHD) machines traditionally rely on diesel engines, but battery-electric loaders equipped with fast-charging battery systems significantly reduce downtime and operational emissions in underground mining environments. Fast-charging battery technology enables these loaders to achieve rapid replenishment, often within minutes, enhancing productivity while minimizing ventilation costs and improving miner safety.

Automated Load-and-Haul Cycles

Automated load-and-haul cycles in mining significantly improve operational efficiency by integrating Load-Haul-Dump (LHD) machines with advanced automation systems, resulting in precise navigation and optimized material transport. Battery-electric loaders enhance these cycles through reduced emissions, lower maintenance costs, and increased energy efficiency, supporting sustainable mining operations.

Swappable Battery Packs

Load-haul-dump (LHD) machines with swappable battery packs enhance operational uptime by enabling rapid battery replacement, reducing downtime compared to traditional charging cycles in battery-electric loaders. Swappable battery technology facilitates continuous underground mining operations, improves energy efficiency, and lowers emissions, positioning battery-electric loaders as a sustainable alternative to diesel-powered LHDs.

Regenerative Braking Integration

Load-haul-dump (LHD) vehicles equipped with regenerative braking systems capture kinetic energy during deceleration, improving energy efficiency and reducing fuel consumption in underground mining operations. Battery-electric loaders further enhance this process by integrating regenerative braking with high-capacity lithium-ion batteries, enabling extended operational cycles and lower greenhouse gas emissions compared to diesel-powered LHDs.

Emissions-free Drift Deployment

Battery-electric loaders provide emissions-free drift deployment by eliminating diesel exhaust emissions and reducing greenhouse gas output, enhancing underground air quality and worker safety. In contrast, traditional load-haul-dump (LHD) machines rely on diesel engines, which produce harmful pollutants and require extensive ventilation systems to maintain air quality in mining tunnels.

Smart Fleet Telematics

Load-haul-dump (LHD) machines equipped with Smart Fleet Telematics enable real-time monitoring of mechanical health and operational efficiency, optimizing underground mining productivity. Battery-electric loaders integrated with advanced telematics offer reduced emissions and enhanced energy management, providing superior data analytics for predictive maintenance and fleet coordination.

Ventilation-on-Demand (VoD) Alignment

Load-haul-dump (LHD) machines powered by traditional diesel emit significant pollutants, increasing ventilation-on-demand (VoD) energy consumption in underground mining operations. Battery-electric loaders drastically reduce diesel emissions, enabling more efficient VoD alignment that lowers fan power needs and improves air quality while cutting operational costs.

BEV (Battery Electric Vehicle) Lifecycle Cost Analysis

Battery-electric loaders exhibit significantly lower lifecycle costs compared to traditional load-haul-dump machines due to reduced fuel consumption, decreased maintenance expenses, and extended component longevity. The total cost of ownership for BEV loaders often decreases by up to 30%, driven by savings in energy costs, lower emissions compliance fees, and increased operational efficiency in underground mining operations.

Diesel Displacement Metrics

Battery-electric loaders significantly reduce diesel displacement metrics by eliminating the need for fuel combustion, lowering greenhouse gas emissions and operational costs compared to traditional load-haul-dump (LHD) machines. Transitioning to battery-electric technology in mining operations can decrease diesel consumption by up to 100%, improve air quality in underground mines, and align with sustainability goals.

Load-haul-dump vs Battery-electric loader Infographic

industrydif.com

industrydif.com