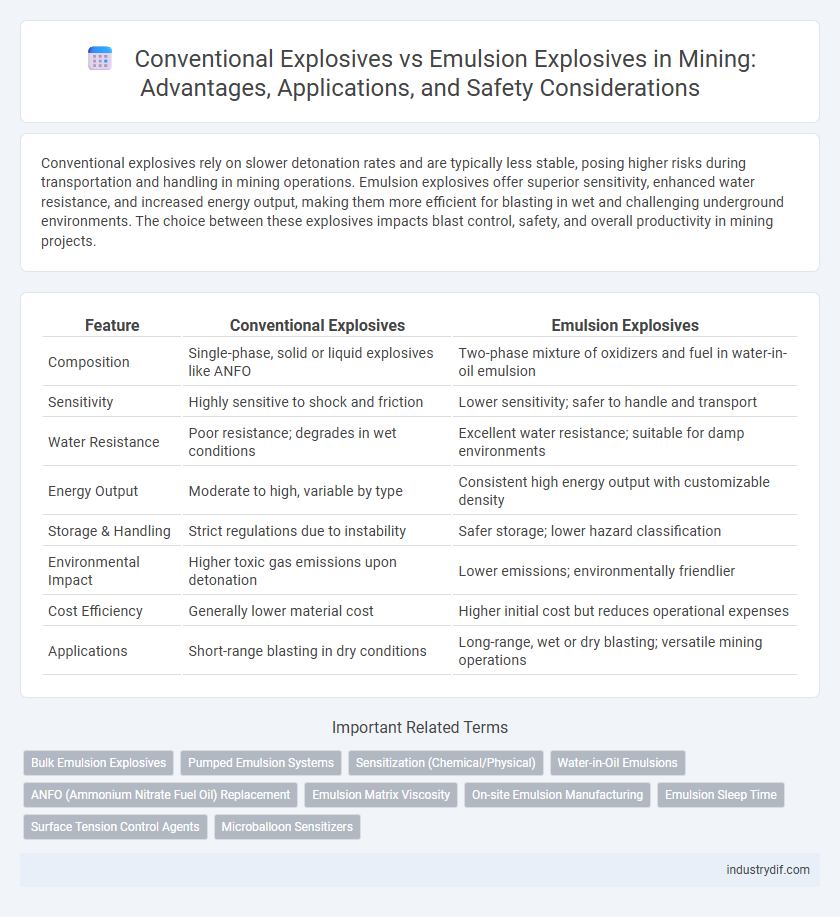

Conventional explosives rely on slower detonation rates and are typically less stable, posing higher risks during transportation and handling in mining operations. Emulsion explosives offer superior sensitivity, enhanced water resistance, and increased energy output, making them more efficient for blasting in wet and challenging underground environments. The choice between these explosives impacts blast control, safety, and overall productivity in mining projects.

Table of Comparison

| Feature | Conventional Explosives | Emulsion Explosives |

|---|---|---|

| Composition | Single-phase, solid or liquid explosives like ANFO | Two-phase mixture of oxidizers and fuel in water-in-oil emulsion |

| Sensitivity | Highly sensitive to shock and friction | Lower sensitivity; safer to handle and transport |

| Water Resistance | Poor resistance; degrades in wet conditions | Excellent water resistance; suitable for damp environments |

| Energy Output | Moderate to high, variable by type | Consistent high energy output with customizable density |

| Storage & Handling | Strict regulations due to instability | Safer storage; lower hazard classification |

| Environmental Impact | Higher toxic gas emissions upon detonation | Lower emissions; environmentally friendlier |

| Cost Efficiency | Generally lower material cost | Higher initial cost but reduces operational expenses |

| Applications | Short-range blasting in dry conditions | Long-range, wet or dry blasting; versatile mining operations |

Introduction to Mining Explosives

Conventional explosives such as ANFO and dynamite have been widely used in mining for their ease of handling and established performance, but they often present limitations in water resistance and energy efficiency. Emulsion explosives offer enhanced stability, improved water resistance, higher energy output, and safer handling due to their non-toxic ingredients, making them increasingly preferred in modern mining operations. The transition from conventional to emulsion explosives is driven by the need for greater blasting efficiency, reduced environmental impact, and improved safety standards in the mining industry.

Overview of Conventional Explosives

Conventional explosives in mining primarily include ANFO (Ammonium Nitrate Fuel Oil) and dynamite, known for their established use and cost-effectiveness in fragmentation and rock displacement. These explosives offer predictable performance under various geological conditions but exhibit limitations in sensitivity and water resistance. Their widespread availability and simplicity make them a standard choice, although safety concerns and environmental impact drive the search for advanced alternatives like emulsion explosives.

Understanding Emulsion Explosives

Emulsion explosives consist of a water-in-oil emulsion matrix that enhances stability and sensitivity compared to conventional explosives like ANFO. Their higher water resistance and safety characteristics make them ideal for use in wet or complex mining environments. Emulsion explosives provide improved energy output and controlled detonation velocity, optimizing blast efficiency and reducing environmental impact.

Chemical Composition Comparison

Conventional explosives typically consist of nitroglycerin or ammonium nitrate mixed with fuel oil, resulting in a relatively simple chemical composition with lower water resistance. Emulsion explosives feature a complex matrix of ammonium nitrate droplets suspended in a fuel-rich, water-in-oil emulsion, enhancing stability and water resistance. The chemical composition of emulsion explosives allows for higher detonation velocity and improved safety compared to conventional explosives.

Safety Considerations in Handling

Conventional explosives require strict adherence to handling protocols due to their high sensitivity to shock, friction, and temperature, increasing the risk of accidental detonation. Emulsion explosives offer enhanced safety with reduced sensitivity and greater water resistance, minimizing hazards during transportation and storage in mining operations. Proper training and the use of specialized equipment remain essential for safely managing both types of explosives in underground and surface mining environments.

Storage and Transportation Differences

Conventional explosives require stringent storage conditions with high sensitivity to temperature and humidity, often necessitating specialized magazines and strict regulatory compliance for transportation due to their volatile nature. Emulsion explosives offer enhanced stability, enabling safer storage at ambient temperatures and reducing the need for complex environmental controls during handling and transit. These stability advantages result in lower transportation risks and logistical costs, making emulsion explosives preferable for certain mining operations.

Performance and Blast Efficiency

Conventional explosives like ANFO typically offer lower energy output and variable detonation sensitivity compared to emulsion explosives, which provide higher detonation velocity and better water resistance, resulting in more consistent blast performance. Emulsion explosives enhance fragmentation and reduce ground vibration due to their superior energy distribution and uniform density. Blast efficiency in mining operations improves with emulsions as they allow precise tailoring of explosive properties, optimizing rock breakage and minimizing waste.

Environmental Impact and Regulations

Conventional explosives typically contain nitroglycerin and other high-energy compounds that release higher levels of toxic gases and residues, impacting air and soil quality in mining sites. Emulsion explosives offer improved environmental performance through lower chemical oxygen demand and reduced noxious gas emissions, making them preferable under stringent environmental regulations such as those enforced by the EPA and OSHA. Regulatory frameworks increasingly favor emulsion explosives due to their safer handling properties and minimized ecological footprint during blasting operations.

Cost Analysis and Economic Factors

Conventional explosives typically incur higher transportation and storage costs due to sensitivity and regulatory requirements, impacting the overall mining budget. Emulsion explosives offer cost advantages through safer handling, longer shelf life, and on-site mixing capabilities, reducing logistics expenses and minimizing downtime. Evaluating the total cost of ownership, including purchase price, handling ease, and operational efficiency, favors emulsion explosives in large-scale mining operations with tight economic constraints.

Future Trends in Explosive Technologies

Future trends in explosive technologies for mining emphasize the development of emulsion explosives due to their higher energy output, improved safety, and environmental benefits compared to conventional explosives. Research is increasingly focused on optimizing the formulation of emulsion explosives to enhance stability, reduce sensitivity, and boost blast efficiency, contributing to more precise fragmentation and reduced ground vibrations. Advancements in digital blasting techniques combined with emulsion explosives enable real-time monitoring and control, supporting sustainable mining operations and minimizing operational risks.

Related Important Terms

Bulk Emulsion Explosives

Bulk emulsion explosives consist of a water-in-oil emulsion matrix that provides superior safety, stability, and sensitivity control compared to conventional explosives, making them ideal for large-scale mining operations. Their ability to be formulated on-site reduces transportation risks and allows for precise energy optimization, leading to enhanced fragmentation and reduced environmental impact.

Pumped Emulsion Systems

Pumped emulsion systems, a key innovation within emulsion explosives, offer superior stability, higher energy density, and safer handling compared to conventional explosives commonly used in mining. These systems enable precise control over detonation velocity and reduced sensitivity to environmental factors, significantly enhancing blasting efficiency and operational safety in complex mining operations.

Sensitization (Chemical/Physical)

Conventional explosives rely on chemical sensitization through additives like aluminum powder or nitrate compounds to initiate detonation, whereas emulsion explosives utilize physical sensitization by incorporating gas bubbles or microbubbles dispersed within a viscous matrix to enhance shock wave propagation. Emulsion explosives offer improved stability and controlled sensitization, reducing sensitivity to accidental initiation compared to chemically sensitized conventional explosives.

Water-in-Oil Emulsions

Water-in-oil emulsion explosives in mining offer superior stability, higher energy output, and reduced sensitivity compared to conventional explosives such as ANFO. These emulsions consist of a dispersed aqueous oxidizer phase within a continuous oil phase, enabling enhanced water resistance and safer storage while improving blasting efficiency and fragmentation quality.

ANFO (Ammonium Nitrate Fuel Oil) Replacement

Emulsion explosives offer superior water resistance and higher detonation velocities compared to conventional ANFO (Ammonium Nitrate Fuel Oil), making them a preferred choice for challenging mining environments. Their enhanced energy output and safer handling reduce overall operational costs and improve blasting efficiency in large-scale mining operations.

Emulsion Matrix Viscosity

The emulsion matrix viscosity in emulsion explosives significantly enhances stability and sensitivity control compared to conventional explosives, allowing for safer handling and improved blast performance. Higher viscosity in the emulsion matrix reduces segregation of components, ensuring uniform energy distribution and consistent detonation velocity in mining operations.

On-site Emulsion Manufacturing

On-site emulsion manufacturing in mining offers enhanced safety and flexibility compared to conventional explosives, enabling precise blending tailored to specific blast requirements and reducing transportation risks. This method improves operational efficiency by minimizing storage hazards and allowing for immediate adjustments in explosive formulations, ultimately optimizing blast performance and cost-effectiveness.

Emulsion Sleep Time

Emulsion explosives exhibit significantly longer sleep times compared to conventional explosives, allowing for enhanced storage stability and flexibility in blasting schedules across mining operations. Their water-in-oil matrix structure resists premature detonation, improving safety and reliability in varied environmental conditions.

Surface Tension Control Agents

Surface tension control agents in conventional explosives primarily regulate the wetting properties to ensure uniform mixing of ingredients, whereas in emulsion explosives, these agents are crucial for stabilizing the water-in-oil emulsion, preventing phase separation and enhancing sensitivity. Effective surface tension control improves the efficiency of detonation and increases safety by maintaining homogeneity in emulsion explosives commonly used in surface mining operations.

Microballoon Sensitizers

Microballoon sensitizers enhance the density and stability of emulsion explosives, providing better energy distribution and controlled detonation compared to conventional explosives, which rely on traditional sensitizing agents with less uniformity. Emulsion explosives with microballoon sensitizers offer improved blasting efficiency and reduced sensitivity to environmental factors, making them more effective and safer in mining operations.

Conventional Explosives vs Emulsion Explosives Infographic

industrydif.com

industrydif.com