Tailings and paste backfill technology serve different roles in mining waste management, with tailings being the leftover materials after ore extraction, typically stored in surface impoundments, while paste backfill involves mixing tailings with binders to create a thick, stable slurry for underground mine support. Paste backfill technology enhances mine safety by providing ground support and minimizing surface storage footprints, reducing environmental risks associated with tailings dams. This method also promotes resource efficiency by enabling the reuse of tailings, contributing to sustainable mining practices.

Table of Comparison

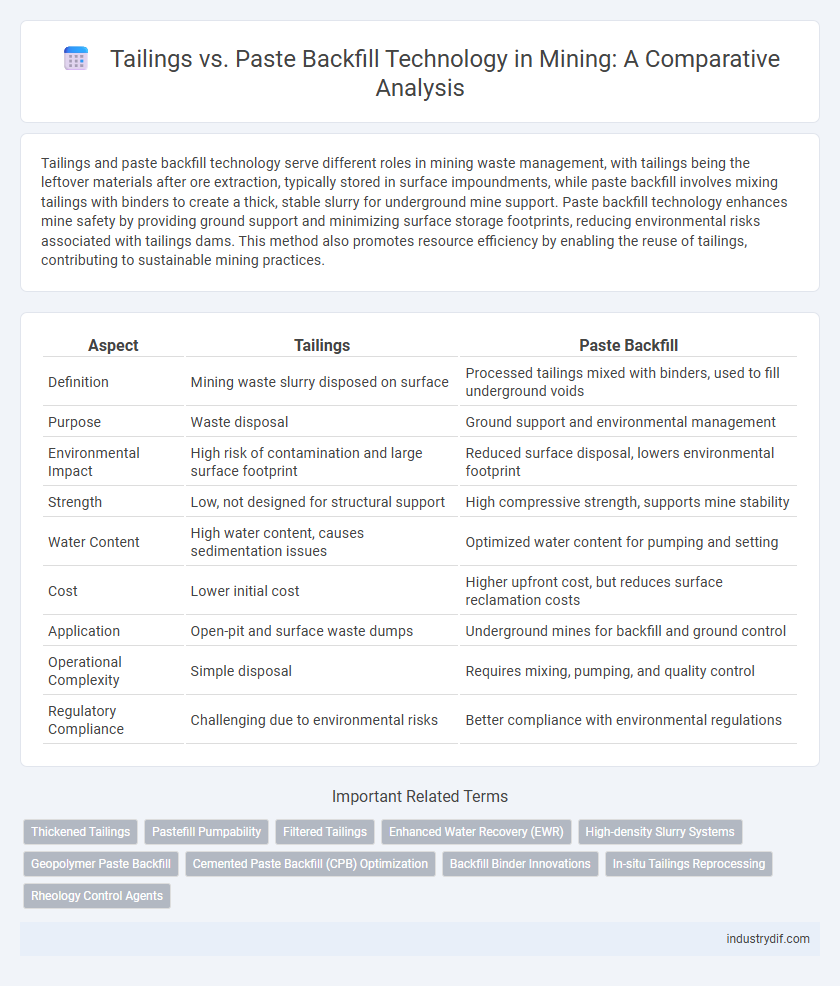

| Aspect | Tailings | Paste Backfill |

|---|---|---|

| Definition | Mining waste slurry disposed on surface | Processed tailings mixed with binders, used to fill underground voids |

| Purpose | Waste disposal | Ground support and environmental management |

| Environmental Impact | High risk of contamination and large surface footprint | Reduced surface disposal, lowers environmental footprint |

| Strength | Low, not designed for structural support | High compressive strength, supports mine stability |

| Water Content | High water content, causes sedimentation issues | Optimized water content for pumping and setting |

| Cost | Lower initial cost | Higher upfront cost, but reduces surface reclamation costs |

| Application | Open-pit and surface waste dumps | Underground mines for backfill and ground control |

| Operational Complexity | Simple disposal | Requires mixing, pumping, and quality control |

| Regulatory Compliance | Challenging due to environmental risks | Better compliance with environmental regulations |

Understanding Tailings in Mining Operations

Tailings in mining operations refer to the fine-grained waste material left after the extraction of valuable minerals, often stored in tailings dams or impoundments. Compared to paste backfill technology, which recycles tailings mixed with binding agents to fill underground voids and enhance stability, traditional tailings disposal poses higher environmental risks and land use challenges. Understanding the physical and chemical properties of tailings is crucial for optimizing waste management and improving the sustainability of mining operations.

Introduction to Paste Backfill Technology

Paste backfill technology uses a mixture of tailings, water, and binders to create a semi-solid material that is pumped into mined-out voids, providing structural support and reducing surface storage of tailings. This method enhances mine safety by minimizing the risk of ground subsidence and allows for improved tailings management with reduced environmental impact. Compared to traditional tailings disposal, paste backfill offers increased stability, lowered water usage, and better resource recovery within underground mining operations.

Composition and Characteristics of Tailings

Tailings consist primarily of finely ground rock particles suspended in water, often containing residual minerals and chemicals from ore processing, which require careful management due to their potential environmental hazards. Their composition varies depending on the ore type and extraction method but typically includes silicates, sulfides, and traces of heavy metals, affecting their stability and reactivity. Compared to paste backfill, tailings have higher water content and lower cohesiveness, resulting in greater susceptibility to seepage and structural failure if not properly contained.

How Paste Backfill Works: Process Overview

Paste backfill technology involves mixing mill tailings with water and binders like cement to create a thick, viscous slurry. This slurry is pumped underground through pipelines to fill mined-out voids, providing ground support and reducing surface tailings disposal. The process improves mine stability and minimizes environmental impacts by recycling tailings within the mine.

Environmental Impacts: Tailings vs Paste Backfill

Tailings disposal often leads to significant environmental challenges such as soil and water contamination due to the release of heavy metals and process chemicals, causing long-term ecological damage. Paste backfill technology reduces these impacts by recycling tailings into a stable, dense material that minimizes surface storage and contamination risks while enhancing mine safety through ground support. Implementing paste backfill also reduces the footprint of tailings storage facilities, lowers dust generation, and mitigates acid mine drainage, contributing to improved environmental sustainability in mining operations.

Economic Considerations and Cost Efficiency

Tailings backfill technology generally requires lower upfront capital investment but can lead to higher long-term storage and environmental management costs due to the volume of tailings processed. Paste backfill technology, although involving higher initial costs for specialized equipment and binders, improves mine safety and reduces waste storage expenses by utilizing paste's higher solids content and stability. Economic evaluations favor paste backfill in mines prioritizing operational efficiency and regulatory compliance, as reduced dilution and improved ground support lead to enhanced ore recovery and lower overall lifecycle costs.

Safety and Risk Management in Tailings and Paste Backfill

Tailings storage facilities (TSFs) pose significant safety risks including dam failures, seepage, and environmental contamination, requiring rigorous monitoring and engineering controls. Paste backfill technology enhances risk management by stabilizing underground voids with thickened tailings, reducing surface tailings volumes, and improving structural integrity underground. This method minimizes tailings dam reliance, lowers the likelihood of catastrophic failures, and supports safer mine operations by controlling ground subsidence and reducing surface environmental hazards.

Advances in Tailings Management Techniques

Advances in tailings management techniques have significantly shifted the industry towards safer and more sustainable practices, with paste backfill technology emerging as a key innovation. Unlike conventional tailings disposal, paste backfill uses thickened tailings mixed with binders to create a stable, cement-like material that can be reused underground, reducing surface storage risks and environmental impact. This technology enhances mine productivity, mitigates tailings dam failures, and supports regulatory compliance through improved containment and reclamation strategies.

Comparative Case Studies: Industry Applications

Comparative case studies in mining reveal tailings backfill is widely used for underground void filling but presents challenges like higher water content and lower strength, affecting ground stability. Paste backfill technology, characterized by its higher solids concentration and improved mechanical properties, demonstrates superior performance in mines such as the Kidd Creek Mine in Canada and the San Andres Mine in Colombia, enhancing safety and reducing environmental impact. Economic assessments indicate paste backfill reduces treatment and disposal costs while enabling deeper extraction and extended mine life compared to conventional tailings backfill.

Future Trends in Tailings and Paste Backfill Technologies

Future trends in tailings and paste backfill technologies emphasize sustainable mining practices, with developments targeting enhanced water recovery and reduced environmental impact. Innovations in paste backfill formulations are improving strength and stability, allowing safer underground void filling and minimizing surface tailings storage. Integration of real-time monitoring and automation is expected to optimize material properties and placement, further advancing operational efficiency and safety in mining operations.

Related Important Terms

Thickened Tailings

Thickened tailings technology enhances mine waste management by increasing solids concentration, reducing water content, and improving stability compared to conventional tailings storage. Utilizing paste backfill methods with thickened tailings minimizes environmental impact and allows safer underground void filling, optimizing resource recovery and operational safety.

Pastefill Pumpability

Paste backfill technology enhances mine safety and recovery by using tailings mixed with binders to create a pumpable slurry that supports underground voids. Optimized pastefill pumpability reduces segregation and blockages in pipelines, ensuring consistent flow rates and minimizing equipment wear for efficient underground placement.

Filtered Tailings

Filtered tailings technology significantly reduces water usage by dewatering tailings to a low moisture content before placement, enhancing geotechnical stability compared to conventional paste backfill. This method minimizes environmental impact through improved water recycling and tailings consolidation, leading to safer storage facilities and reduced seepage risks.

Enhanced Water Recovery (EWR)

Tailings thickening and paste backfill technology significantly improve Enhanced Water Recovery (EWR) in mining operations by reducing water loss and enabling efficient recycling of process water. Utilizing high-density paste backfill not only minimizes environmental impact but also increases water recovery rates by up to 70%, supporting sustainable mining practices.

High-density Slurry Systems

High-density slurry systems in paste backfill technology utilize a controlled mixture of tailings, cement, and water to create a dense, stable material that enhances underground mine stability while reducing environmental tailings storage. Compared to conventional tailings disposal, paste backfill minimizes waste volume, improves resource recovery, and significantly lowers the risk of tailings dam failures.

Geopolymer Paste Backfill

Geopolymer paste backfill technology offers enhanced environmental benefits and improved structural stability compared to traditional tailings disposal by converting mining waste into a reusable binder, reducing reliance on cement and lowering carbon emissions. This sustainable approach utilizes industrial by-products like fly ash and slag to create a dense, durable fill that strengthens underground stopes while minimizing the risk of ground subsidence and tailings dam failures.

Cemented Paste Backfill (CPB) Optimization

Cemented Paste Backfill (CPB) optimization enhances mine safety and environmental management by improving the strength and stability of underground voids using a specific ratio of tailings, binders, and water. Advanced techniques in CPB mix design and placement reduce cement consumption and water usage while maximizing the reuse of tailings, thus minimizing surface tailings storage and associated environmental risks.

Backfill Binder Innovations

Backfill binder innovations in mining emphasize sustainable and cost-effective materials such as cementitious by-products, geopolymers, and industrial waste to enhance paste backfill strength and durability while reducing environmental impact. Advances in binder formulations improve the mechanical properties and hydration process, enabling more reliable underground tailings management compared to traditional tailings disposal methods.

In-situ Tailings Reprocessing

In-situ tailings reprocessing using paste backfill technology enhances mine safety and environmental sustainability by stabilizing underground voids and reducing surface tailings dams. This method optimizes resource recovery by reintegrating fine tailings into the mining cycle, minimizing waste and lowering ecological impact.

Rheology Control Agents

Rheology control agents in tailings and paste backfill technology optimize the flow properties, ensuring stability and effective placement within underground mines. These agents enhance viscosity and shear strength, reducing segregation and improving settlement rates to minimize environmental impact and improve operational efficiency.

Tailings vs Paste backfill technology Infographic

industrydif.com

industrydif.com