Drilling in mining involves creating precise boreholes to extract core samples, providing crucial geological data for resource evaluation. Ore sorting enhances operational efficiency by separating valuable minerals from waste rock based on physical or chemical properties before processing. Combining drilling insights with advanced ore sorting technologies optimizes resource recovery and reduces overall mining costs.

Table of Comparison

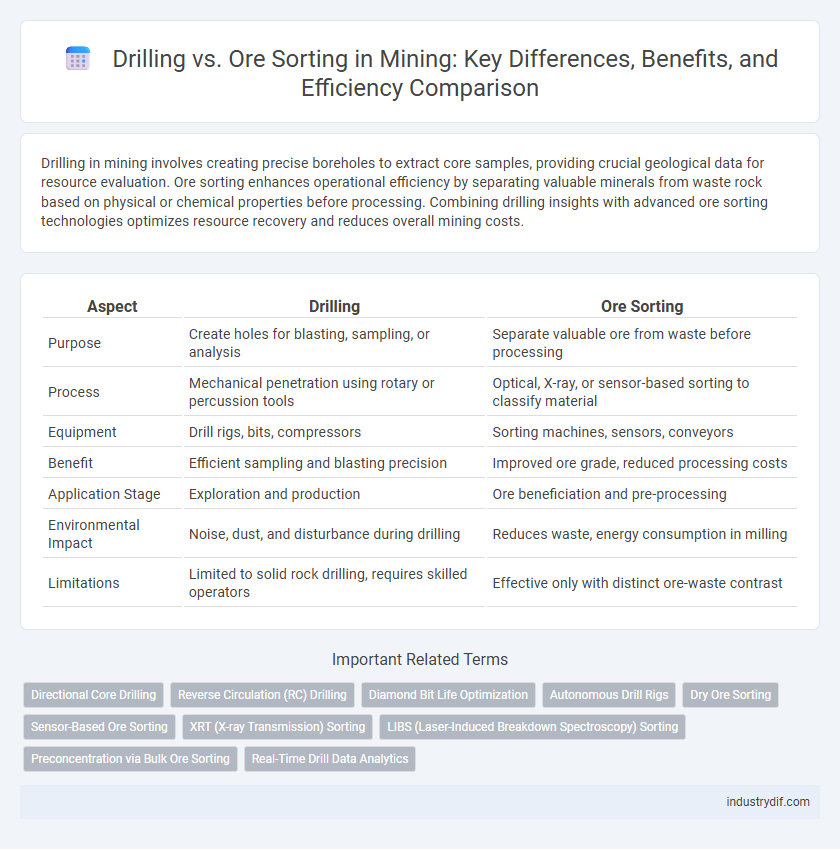

| Aspect | Drilling | Ore Sorting |

|---|---|---|

| Purpose | Create holes for blasting, sampling, or analysis | Separate valuable ore from waste before processing |

| Process | Mechanical penetration using rotary or percussion tools | Optical, X-ray, or sensor-based sorting to classify material |

| Equipment | Drill rigs, bits, compressors | Sorting machines, sensors, conveyors |

| Benefit | Efficient sampling and blasting precision | Improved ore grade, reduced processing costs |

| Application Stage | Exploration and production | Ore beneficiation and pre-processing |

| Environmental Impact | Noise, dust, and disturbance during drilling | Reduces waste, energy consumption in milling |

| Limitations | Limited to solid rock drilling, requires skilled operators | Effective only with distinct ore-waste contrast |

Introduction to Drilling and Ore Sorting in Mining

Drilling in mining involves creating precise boreholes to access mineral deposits, facilitating efficient extraction and blasting operations. Ore sorting uses advanced sensor-based technology to separate valuable minerals from waste rock, optimizing processing efficiency and reducing operational costs. Integrating drilling with ore sorting enhances resource recovery and minimizes environmental impact by targeting high-grade materials.

Core Principles of Drilling Techniques

Drilling techniques in mining focus on precision, efficiency, and depth control to extract core samples that accurately represent ore bodies. Core drilling involves using diamond-tipped drill bits to penetrate various rock formations while maintaining sample integrity for geological analysis. Effective drilling optimizes resource estimation and guides subsequent processes such as ore sorting, which separates valuable minerals from waste based on physical or chemical properties.

Fundamentals of Ore Sorting Technologies

Ore sorting technologies leverage sensor-based systems to differentiate valuable minerals from waste rock by analyzing physical and chemical properties such as density, conductivity, and spectral response. Drilling primarily focuses on extracting core samples for geological assessment, whereas ore sorting emphasizes real-time separation on the processing line to enhance feed quality and reduce downstream processing costs. Advanced sorting methods, including X-ray transmission and near-infrared spectroscopy, improve the efficiency and sustainability of mineral beneficiation in modern mining operations.

Comparing Efficiency: Drilling vs Ore Sorting

Drilling efficiency in mining is primarily measured by penetration rate and accuracy, with advanced rigs achieving over 500 meters per day, while ore sorting enhances efficiency by pre-concentrating valuable minerals, reducing processing volume by up to 30%. Ore sorting technologies like X-ray transmission and laser-induced breakdown spectroscopy optimize feed quality, significantly lowering energy consumption compared to conventional drilling and milling. Combining precise drilling data with real-time ore sorting results maximizes overall extraction efficiency and operational cost savings in mineral processing.

Cost Implications in Drilling and Ore Sorting

Drilling incurs substantial costs due to equipment, labor, and maintenance expenses, often representing a significant portion of mining operational budgets. Ore sorting reduces downstream processing costs by pre-concentration, minimizing the volume of material transported and processed. Implementing advanced sensor-based ore sorting technology can lead to cost savings of up to 30% compared to traditional drilling and blasting methods, enhancing overall mine profitability.

Environmental Impact: Drilling vs Ore Sorting

Drilling in mining generates significant dust, noise, and waste rock, contributing to air and water pollution as well as habitat disruption. Ore sorting minimizes environmental impact by reducing the volume of material processed, lowering energy consumption, and decreasing tailings production. Implementing ore sorting technology leads to improved resource efficiency and less environmental degradation compared to conventional drilling practices.

Technological Advancements in Drilling Methods

Technological advancements in drilling methods, such as directional drilling, automated rigs, and real-time data analytics, have significantly enhanced precision and efficiency in mineral extraction. Improved drill bit materials and designs increase penetration rates and durability, reducing operational costs and environmental impact. These innovations outperform traditional ore sorting techniques by enabling targeted extraction from complex ore bodies, optimizing resource recovery.

Innovation in Sensor-Based Ore Sorting

Sensor-based ore sorting revolutionizes mining by using advanced sensors such as X-ray transmission, near-infrared, and laser-induced breakdown spectroscopy to accurately differentiate valuable minerals from waste rock. This innovation reduces the need for extensive drilling, lowers operational costs, and minimizes environmental impact by optimizing ore processing efficiency. Improved sensor technologies facilitate real-time data analysis, enabling precise, high-throughput sorting that enhances resource recovery and supports sustainable mining practices.

Integration of Drilling and Ore Sorting in Mining Operations

Integrating drilling and ore sorting in mining operations enhances resource efficiency by enabling precise classification of ore during extraction. Real-time data from drilling sensors informs the sorting process, optimizing the separation of valuable minerals from waste rock. This synergy reduces processing costs, improves recovery rates, and supports sustainable mining practices.

Future Trends: Automation and Digitalization in Drilling and Ore Sorting

Future trends in mining emphasize automation and digitalization to enhance drilling efficiency and ore sorting accuracy. Advanced sensors, AI-driven analytics, and real-time data integration optimize drilling parameters and ore grade identification, reducing operational costs and environmental impact. Digital twins and autonomous equipment further revolutionize ore extraction by enabling predictive maintenance and adaptive sorting processes.

Related Important Terms

Directional Core Drilling

Directional core drilling enhances precision in mineral exploration by enabling targeted sampling along predetermined borehole trajectories, thereby improving ore body characterization and reducing waste extraction. Compared to ore sorting, this technique provides high-resolution subsurface data that optimizes drilling efficiency and maximizes resource recovery in complex geological environments.

Reverse Circulation (RC) Drilling

Reverse Circulation (RC) drilling enhances mineral exploration efficiency by delivering faster, uncontaminated samples directly from the drill face, improving ore body modeling accuracy compared to traditional ore sorting methods that rely on post-extraction material analysis. This technique reduces overall costs and environmental impact by minimizing waste generation and increasing the precision of grade control in mining operations.

Diamond Bit Life Optimization

Diamond bit life optimization extends operational efficiency by reducing wear through precise drilling parameters and effective ore sorting that minimizes non-valuable material processing. Advanced ore sorting technology enhances drill bit longevity by limiting exposure to abrasive waste rock, directly lowering replacement frequency and operational downtime.

Autonomous Drill Rigs

Autonomous drill rigs enhance mining efficiency by enabling precise, real-time data collection and optimized drilling patterns, reducing operational costs and minimizing environmental impact compared to traditional ore sorting methods. Integrating AI-driven autonomous drilling technologies accelerates resource extraction with higher accuracy, improving overall mine productivity and resource recovery rates.

Dry Ore Sorting

Dry ore sorting enhances mining efficiency by enabling precise separation of valuable minerals from waste without water usage, reducing environmental impact and operational costs. Compared to traditional drilling methods, dry ore sorting accelerates processing times through advanced sensors and automation, optimizing resource recovery and minimizing material handling.

Sensor-Based Ore Sorting

Sensor-based ore sorting enhances mining efficiency by using optical, X-ray, or electromagnetic sensors to rapidly separate valuable ore from waste rock, reducing drilling and processing costs. This technology minimizes energy consumption and environmental impact by improving grade control and decreasing the volume of material requiring downstream crushing and milling.

XRT (X-ray Transmission) Sorting

XRT (X-ray Transmission) Sorting enhances ore sorting efficiency by using X-ray technology to differentiate materials based on atomic density, enabling precise separation of valuable ore from waste during the mining process. Compared to traditional drilling, XRT sorting reduces material volume sent for processing, lowers energy consumption, and increases recovery rates, optimizing overall operational costs and environmental impact.

LIBS (Laser-Induced Breakdown Spectroscopy) Sorting

LIBS sorting enhances ore sorting efficiency by rapidly analyzing elemental composition through laser-induced plasma emission, enabling real-time, high-precision mineral identification during mining operations. Compared to traditional drilling, LIBS sorting reduces sample processing time and operational costs while improving material recovery and environmental sustainability in mineral extraction.

Preconcentration via Bulk Ore Sorting

Preconcentration via bulk ore sorting enhances mining efficiency by separating valuable minerals from waste rock before processing, reducing energy consumption and increasing ore grade. This method complements drilling by providing real-time data to optimize blast design and minimize dilution, leading to cost-effective mineral extraction.

Real-Time Drill Data Analytics

Real-time drill data analytics enhances ore sorting accuracy by providing immediate insights into mineral composition during drilling, reducing waste and optimizing resource extraction. Integrating sensor data with advanced algorithms enables precise identification of ore boundaries, accelerating decision-making and improving overall mining efficiency.

Drilling vs Ore Sorting Infographic

industrydif.com

industrydif.com