3D printing in scientific pet applications enables the precise fabrication of complex structures such as implants and prosthetics, enhancing animal care and research models. 4D bioprinting advances this technology by incorporating time-responsive materials that can change shape or function post-printing, allowing dynamic tissue engineering and regenerative studies. This evolution from static to adaptive constructs transforms potential treatments and experimental approaches in veterinary science.

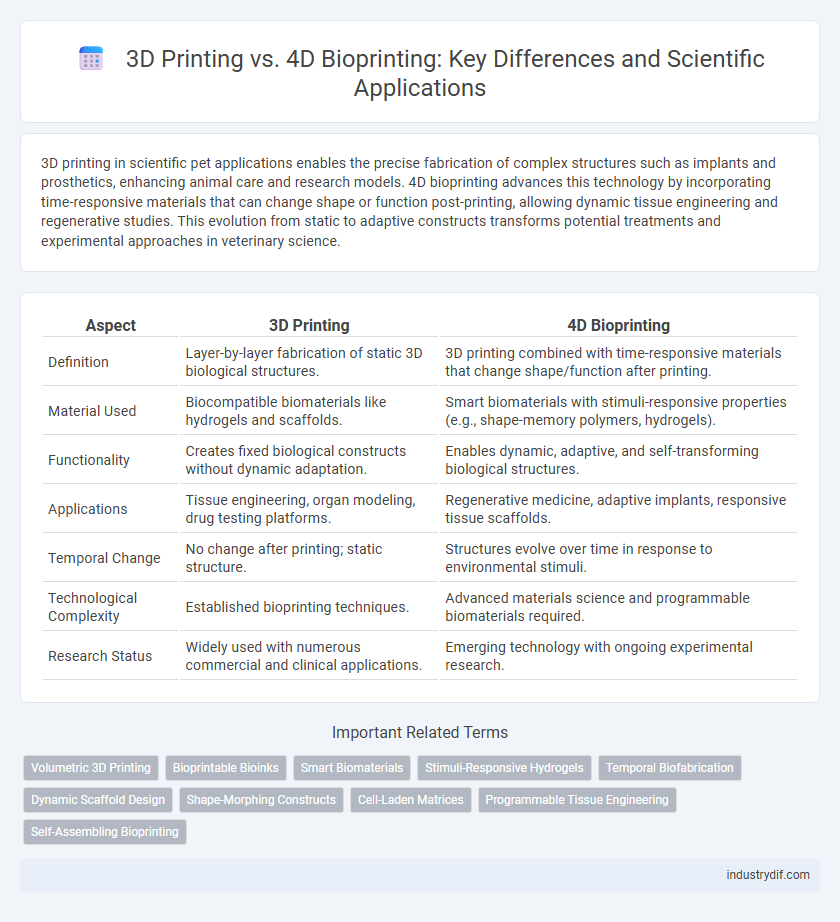

Table of Comparison

| Aspect | 3D Printing | 4D Bioprinting |

|---|---|---|

| Definition | Layer-by-layer fabrication of static 3D biological structures. | 3D printing combined with time-responsive materials that change shape/function after printing. |

| Material Used | Biocompatible biomaterials like hydrogels and scaffolds. | Smart biomaterials with stimuli-responsive properties (e.g., shape-memory polymers, hydrogels). |

| Functionality | Creates fixed biological constructs without dynamic adaptation. | Enables dynamic, adaptive, and self-transforming biological structures. |

| Applications | Tissue engineering, organ modeling, drug testing platforms. | Regenerative medicine, adaptive implants, responsive tissue scaffolds. |

| Temporal Change | No change after printing; static structure. | Structures evolve over time in response to environmental stimuli. |

| Technological Complexity | Established bioprinting techniques. | Advanced materials science and programmable biomaterials required. |

| Research Status | Widely used with numerous commercial and clinical applications. | Emerging technology with ongoing experimental research. |

Introduction to 3D Printing and 4D Bioprinting

3D printing involves layer-by-layer fabrication of biological structures using biomaterials and cells, enabling the creation of static tissue scaffolds with precise geometries. 4D bioprinting extends this technology by integrating time as a factor, producing dynamic constructs that can change shape, function, or properties in response to environmental stimuli such as temperature, pH, or light. This advancement leverages smart materials like shape-memory polymers to enable regeneration and adaptive tissue engineering applications.

Fundamental Principles of 3D Printing

3D printing involves the layer-by-layer deposition of biocompatible materials to create three-dimensional structures with precise spatial control. It relies on digital models to accurately reproduce complex geometries, utilizing techniques such as extrusion, inkjet, or laser-assisted printing. The fundamental principle of 3D printing centers on fabricating static constructs that do not change shape or properties over time.

Evolution Towards 4D Bioprinting

3D printing in biomedicine involves layer-by-layer deposition of biomaterials to create static structures, mainly for tissue scaffolds and organ models. The evolution to 4D bioprinting integrates time as the fourth dimension, enabling printed constructs to change shape, function, or properties in response to environmental stimuli. This advancement leverages smart biomaterials and dynamic cellular responses, offering significant progress in tissue engineering, regenerative medicine, and personalized therapeutics.

Key Materials in 3D and 4D Bioprinting

Key materials in 3D bioprinting primarily include hydrogels such as alginate, gelatin, and synthetic polymers, which provide structural support and biocompatibility for cell encapsulation. In 4D bioprinting, stimuli-responsive materials such as shape-memory polymers, hydrogels with dynamic crosslinking, and nano-composites enable printed constructs to transform over time in response to environmental triggers like temperature, pH, or moisture. The integration of smart biomaterials in 4D bioprinting advances tissue engineering by allowing programmable shape morphing and enhanced functionality beyond static 3D structures.

Mechanisms of Shape and Function Transformation

3D printing creates static biological structures by precisely depositing cells and biomaterials layer-by-layer, enabling the fabrication of tissues with defined shapes but limited dynamic functionality. In contrast, 4D bioprinting incorporates time-responsive materials that change shape or function post-fabrication in response to environmental stimuli such as temperature, pH, or biochemical signals. This dynamic transformation allows 4D bioprinted constructs to mimic physiological behaviors, enhancing their applicability in regenerative medicine and tissue engineering.

Applications in Biomedical Engineering

3D printing in biomedical engineering enables the fabrication of static, patient-specific implants, prosthetics, and tissue scaffolds with precise geometries and biocompatible materials. 4D bioprinting advances this by incorporating time-responsive, stimuli-sensitive biomaterials that dynamically change shape or function, allowing the creation of adaptive tissue constructs and organ models. Applications of 4D bioprinting include engineered tissues that promote regeneration and smart implants that respond to physiological environments, offering transformative potential in personalized medicine and regenerative therapies.

Advantages and Limitations: 3D vs 4D Bioprinting

3D bioprinting enables precise fabrication of static tissue constructs with controlled architecture and cell placement, offering reproducibility and scalability essential for tissue engineering applications. In contrast, 4D bioprinting incorporates time-responsive materials and stimuli-responsive elements, allowing printed structures to change shape, function, or composition dynamically, enhancing adaptability and biomimicry. Limitations of 3D bioprinting include lack of dynamic behavior and limited integration with biological processes, whereas 4D bioprinting faces challenges in material selection, complex design requirements, and controlling stimuli-responsive transformations.

Regulatory and Ethical Considerations

3D printing in biomedical applications faces established regulatory frameworks focusing on material safety and device functionality, whereas 4D bioprinting, involving dynamic, time-responsive biomaterials, presents emerging challenges in regulatory classification and long-term biocompatibility assessment. Ethical considerations for 4D bioprinting include the implications of creating living tissues that can grow or change post-implantation, raising concerns about patient consent, potential unforeseen biological responses, and long-term monitoring obligations. Regulatory agencies are currently developing adaptive guidelines to address these complexities, aiming to balance innovation with patient safety and ethical responsibility in both 3D and 4D bioprinting advancements.

Innovations and Future Trends

3D printing revolutionized biomedical engineering by enabling precise fabrication of static tissue scaffolds, while 4D bioprinting introduces dynamic, stimuli-responsive materials that evolve over time to mimic natural biological processes. Innovations in 4D bioprinting leverage shape-memory polymers and bioinks embedded with living cells, allowing the creation of self-assembling and adaptive tissue constructs essential for regenerative medicine. Future trends emphasize integrating real-time monitoring and AI-driven design to enhance biocompatibility and functional complexity, accelerating personalized treatment solutions.

Conclusion: Impact on Scientific and Medical Fields

3D printing revolutionized medical prototyping and customized implants by enabling rapid fabrication of precise anatomical models and bio-compatible devices. 4D bioprinting advances this technology by incorporating time-responsive materials that adapt post-fabrication, allowing dynamic tissue engineering and regenerative medicine applications. The integration of 4D bioprinting significantly enhances therapeutic potential, enabling the creation of living structures that evolve to meet physiological demands, thereby transforming future clinical treatments and biomedical research.

Related Important Terms

Volumetric 3D Printing

Volumetric 3D printing revolutionizes tissue engineering by fabricating entire structures in seconds through tomographic light projections, surpassing traditional layer-by-layer 3D printing in speed and structural complexity. Unlike 4D bioprinting, which integrates temporal shape transformations and dynamic biological functions, volumetric 3D printing excels in rapid, high-resolution creation of volumetric cell-laden constructs critical for regenerative medicine and complex organ modeling.

Bioprintable Bioinks

3D printing utilizes static bioinks composed primarily of biomaterials like hydrogels and polymers for fabricating tissue scaffolds, while 4D bioprinting employs stimuli-responsive bioinks that dynamically change shape or function over time in response to environmental triggers such as temperature, pH, or light. These intelligent bioinks for 4D bioprinting incorporate smart polymers, cells, and growth factors enabling the creation of biomimetic tissues that evolve post-fabrication, enhancing regenerative medicine and tissue engineering applications.

Smart Biomaterials

Smart biomaterials in 4D bioprinting enable dynamic, responsive structures that adapt to environmental stimuli, surpassing the static nature of traditional 3D printed constructs. These materials facilitate the fabrication of living tissues with the ability to self-assemble, remodel, and evolve over time, crucial for advanced regenerative medicine applications.

Stimuli-Responsive Hydrogels

3D printing in biomedicine primarily involves the fabrication of static structures using hydrogels, whereas 4D bioprinting utilizes stimuli-responsive hydrogels that dynamically change their properties or shape in response to environmental triggers such as temperature, pH, or light. These smart hydrogels enable the creation of adaptive tissues and organs, enhancing the functionality and integration of bioengineered constructs in regenerative medicine.

Temporal Biofabrication

3D printing enables the precise spatial assembly of biological materials to create static tissue constructs, while 4D bioprinting incorporates time as a dynamic component, allowing printed tissues to evolve or respond to environmental stimuli through shape transformation or functional maturation. Temporal biofabrication in 4D bioprinting leverages smart biomaterials and programmed cellular behavior to mimic natural tissue development, enhancing regenerative medicine and customizable therapeutic applications.

Dynamic Scaffold Design

3D printing enables the fabrication of static scaffolds with precise architectures for tissue engineering, whereas 4D bioprinting incorporates time-responsive materials that adapt dynamically to physiological stimuli, promoting cell growth and differentiation. Dynamic scaffold design in 4D bioprinting leverages shape-memory polymers and biomimetic hydrogels to enhance tissue regeneration through controlled morphological transformations.

Shape-Morphing Constructs

3D printing creates static biological structures layer by layer, while 4D bioprinting fabricates dynamic, shape-morphing constructs that respond to environmental stimuli such as temperature, pH, or moisture. Shape-morphing 4D bioprinted constructs enable the development of advanced tissue engineering applications by mimicking the native tissue's adaptive and functional behavior over time.

Cell-Laden Matrices

3D printing fabricates static cell-laden matrices by precisely depositing bioinks layer-by-layer to create three-dimensional tissue constructs with controlled architecture. 4D bioprinting advances this technology by integrating smart biomaterials that enable dynamic transformations in cell-laden matrices over time, responding to environmental stimuli for enhanced tissue regeneration and functionality.

Programmable Tissue Engineering

3D printing enables the fabrication of static biological scaffolds with precise spatial resolution, while 4D bioprinting introduces time as a dynamic factor, allowing engineered tissues to change shape or function in response to specific stimuli. Programmable tissue engineering leverages smart biomaterials and bioinks in 4D bioprinting to achieve dynamic cellular environments that enhance tissue maturation and functional integration.

Self-Assembling Bioprinting

3D printing constructs static biological structures layer by layer, whereas 4D bioprinting incorporates time as a dimension, enabling printed tissues to self-assemble and dynamically change shape or function in response to environmental stimuli. Self-assembling bioprinting leverages smart biomaterials and programmable cells to promote intrinsic organization, enhancing tissue complexity and functionality beyond traditional 3D bioprinting limitations.

3D Printing vs 4D Bioprinting Infographic

industrydif.com

industrydif.com