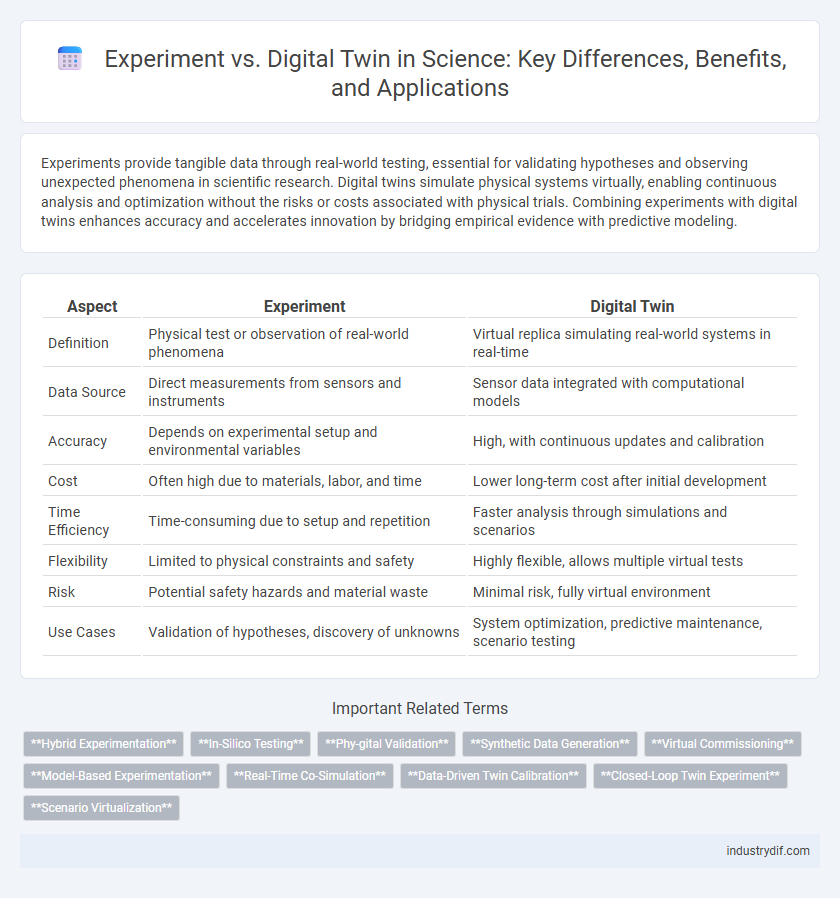

Experiments provide tangible data through real-world testing, essential for validating hypotheses and observing unexpected phenomena in scientific research. Digital twins simulate physical systems virtually, enabling continuous analysis and optimization without the risks or costs associated with physical trials. Combining experiments with digital twins enhances accuracy and accelerates innovation by bridging empirical evidence with predictive modeling.

Table of Comparison

| Aspect | Experiment | Digital Twin |

|---|---|---|

| Definition | Physical test or observation of real-world phenomena | Virtual replica simulating real-world systems in real-time |

| Data Source | Direct measurements from sensors and instruments | Sensor data integrated with computational models |

| Accuracy | Depends on experimental setup and environmental variables | High, with continuous updates and calibration |

| Cost | Often high due to materials, labor, and time | Lower long-term cost after initial development |

| Time Efficiency | Time-consuming due to setup and repetition | Faster analysis through simulations and scenarios |

| Flexibility | Limited to physical constraints and safety | Highly flexible, allows multiple virtual tests |

| Risk | Potential safety hazards and material waste | Minimal risk, fully virtual environment |

| Use Cases | Validation of hypotheses, discovery of unknowns | System optimization, predictive maintenance, scenario testing |

Definition of Experiment and Digital Twin

An experiment is a controlled procedure conducted to test hypotheses, observe phenomena, or validate models by manipulating variables and measuring outcomes. A digital twin is a virtual replica of a physical system, process, or object, continuously updated with real-time data to simulate, predict, and optimize performance. While experiments generate empirical data through direct interaction, digital twins enable ongoing analysis and scenario testing without physical intervention.

Core Principles of Traditional Experiments

Traditional experiments rely on controlled, repeatable procedures to isolate variables and establish causality, ensuring empirical validation through direct observation. They emphasize physical manipulation of real-world systems, enabling tangible data collection and measurement under predefined conditions. Core principles include reproducibility, controlled environments, and systematic variation to rigorously test hypotheses and generate statistically significant results.

Fundamentals of Digital Twin Technology

Digital twin technology integrates real-time data and advanced simulation models to create precise virtual replicas of physical systems, enabling continuous monitoring and predictive analytics. Unlike traditional experiments that are limited by physical constraints, digital twins allow for dynamic scenario testing and system optimization without disrupting actual operations. The fundamental components include sensors for data acquisition, data processing platforms, and simulation algorithms that together facilitate accurate representation and informed decision-making.

Key Differences Between Experiment and Digital Twin

Experiments involve physical testing and data collection under controlled conditions to validate hypotheses or models, while digital twins represent virtual replicas of physical systems that utilize real-time data for simulation and prediction. Unlike experiments, digital twins enable continuous monitoring and scenario analysis without physical intervention, reducing risks and costs. Experiments provide empirical evidence, whereas digital twins enhance understanding through integration of historical, operational, and predictive analytics within a cyber-physical framework.

Applications in Scientific Research

Experiments provide empirical data through controlled physical testing, essential for validating hypotheses in scientific research. Digital twins enable real-time simulation and analysis by creating virtual replicas of physical systems, enhancing predictive accuracy and reducing experimental costs. Combining both approaches accelerates innovation in fields like materials science, biology, and environmental studies by integrating tangible results with advanced computational modeling.

Data Collection and Validation Methods

Experiments generate primary data through controlled physical manipulations, enabling direct observation and validation of phenomena under specific conditions. Digital twins leverage real-time sensor data and simulation models to collect continuous operational data, facilitating dynamic validation by comparing simulated outputs with actual system behavior. Both methods employ rigorous statistical techniques for data accuracy, with experiments focusing on empirical measurement and digital twins emphasizing model calibration and real-world data integration.

Advantages and Limitations of Experiments

Experiments provide direct observation and empirical data essential for validating scientific hypotheses and understanding real-world phenomena with high fidelity. Limitations include high costs, time consumption, and practical constraints in replicating complex or hazardous conditions. Unlike digital twins, experiments lack rapid scalability and flexibility but offer irreplaceable accuracy in capturing unmodeled variables and unexpected behaviors.

Advantages and Limitations of Digital Twins

Digital twins enable real-time monitoring and simulation of physical systems, providing precise data for predictive maintenance and optimization without interrupting actual operations. They offer scalability and cost-efficiency by reducing the need for physical prototypes, yet their accuracy depends heavily on the quality and extent of sensor data and model fidelity. Limitations include challenges in replicating complex, chaotic environments and potential cybersecurity risks associated with digital integration.

Integration of Digital Twins with Physical Experiments

Integrating digital twins with physical experiments enhances precision by enabling real-time data synchronization and simulation of complex scenarios. This integration facilitates iterative refinement of experimental parameters, reducing costs and time associated with physical prototyping. Advanced sensor technologies and machine learning algorithms drive seamless interaction between the digital twin models and experimental setups, optimizing performance analysis and predictive maintenance.

Future Trends in Scientific Experimentation

Future trends in scientific experimentation increasingly leverage digital twin technology to create precise virtual replicas of physical systems, allowing for real-time monitoring and predictive analysis. This integration enhances experimental accuracy while reducing resource consumption and time compared to traditional physical experiments. Advances in AI and machine learning further optimize digital twins, enabling adaptive simulations that evolve with new scientific data and hypotheses.

Related Important Terms

Hybrid Experimentation

Hybrid experimentation combines physical experiments with digital twin simulations, enhancing the accuracy and scalability of scientific research by allowing real-time data integration and predictive analysis. This approach leverages the strengths of both methods to optimize experimental design, reduce costs, and accelerate innovation in complex systems.

In-Silico Testing

In-silico testing leverages digital twins to simulate complex biological and physical processes, enabling precise experimentation without physical prototypes. This approach accelerates hypothesis validation by integrating computational models with real-world data, reducing costs and enhancing predictive accuracy compared to traditional lab experiments.

Phy-gital Validation

Phy-gital validation integrates physical experiments with digital twin simulations to enhance accuracy and reliability in scientific testing. Combining real-world data from experiments with virtual modeling enables comprehensive analysis and iterative optimization of complex systems.

Synthetic Data Generation

Experiment-based synthetic data generation relies on physical models and real-world measurements to produce accurate datasets, while digital twin approaches use virtual replicas of systems to simulate scenarios and generate extensive synthetic data for predictive analytics. Digital twins enable dynamic data synthesis under varying conditions, enhancing model training and validation beyond traditional experimental constraints.

Virtual Commissioning

Virtual commissioning leverages digital twin technology to simulate and validate industrial system operations before physical deployment, reducing errors and downtime significantly. This digital approach contrasts with traditional experimentation by enabling real-time testing and optimization in a virtual environment, accelerating development cycles and enhancing system reliability.

Model-Based Experimentation

Model-based experimentation leverages digital twins to simulate physical systems, enabling precise hypothesis testing and iterative design without the risks and costs associated with real-world experiments. Digital twins integrate real-time data and predictive modeling, enhancing experiment accuracy and accelerating innovation cycles in scientific research.

Real-Time Co-Simulation

Real-time co-simulation integrates physical experiments with digital twin models, enabling synchronized data exchange and iterative validation during system operation. This approach enhances accuracy in predicting complex system behaviors by combining live sensor inputs with advanced computational simulations.

Data-Driven Twin Calibration

Data-driven twin calibration leverages real-time experimental data to continuously update and refine digital twin models, enhancing their predictive accuracy and operational reliability. Integrating sensor-derived datasets with physics-based simulations enables precise alignment between physical experiments and their virtual counterparts, optimizing performance and reducing uncertainty.

Closed-Loop Twin Experiment

Closed-loop twin experiments integrate real-time data feedback between physical experiments and their digital twin counterparts, enabling continuous model updating and validation with high fidelity. This dynamic interaction enhances predictive accuracy and system optimization in complex scientific investigations by closely mirroring actual experimental conditions.

Scenario Virtualization

Scenario virtualization in experiments involves creating controlled physical conditions to test hypotheses, while digital twin technology employs high-fidelity virtual replicas of physical systems for real-time simulation and analysis, enabling dynamic scenario adjustments without physical constraints. Digital twins integrate sensor data and machine learning algorithms to replicate complex system behaviors accurately, optimizing decision-making and predictive maintenance in scientific research.

Experiment vs Digital Twin Infographic

industrydif.com

industrydif.com