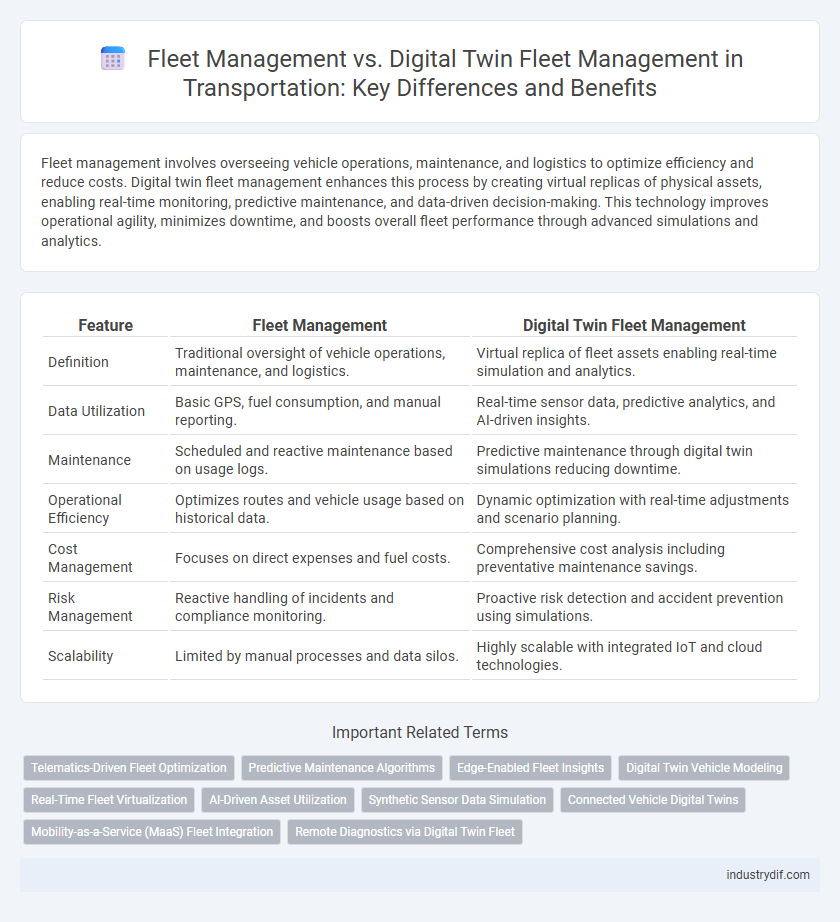

Fleet management involves overseeing vehicle operations, maintenance, and logistics to optimize efficiency and reduce costs. Digital twin fleet management enhances this process by creating virtual replicas of physical assets, enabling real-time monitoring, predictive maintenance, and data-driven decision-making. This technology improves operational agility, minimizes downtime, and boosts overall fleet performance through advanced simulations and analytics.

Table of Comparison

| Feature | Fleet Management | Digital Twin Fleet Management |

|---|---|---|

| Definition | Traditional oversight of vehicle operations, maintenance, and logistics. | Virtual replica of fleet assets enabling real-time simulation and analytics. |

| Data Utilization | Basic GPS, fuel consumption, and manual reporting. | Real-time sensor data, predictive analytics, and AI-driven insights. |

| Maintenance | Scheduled and reactive maintenance based on usage logs. | Predictive maintenance through digital twin simulations reducing downtime. |

| Operational Efficiency | Optimizes routes and vehicle usage based on historical data. | Dynamic optimization with real-time adjustments and scenario planning. |

| Cost Management | Focuses on direct expenses and fuel costs. | Comprehensive cost analysis including preventative maintenance savings. |

| Risk Management | Reactive handling of incidents and compliance monitoring. | Proactive risk detection and accident prevention using simulations. |

| Scalability | Limited by manual processes and data silos. | Highly scalable with integrated IoT and cloud technologies. |

Introduction to Fleet Management

Fleet management involves overseeing and coordinating a company's vehicle fleet to improve efficiency, reduce costs, and ensure compliance with regulations. Key components include vehicle tracking, maintenance scheduling, fuel management, and driver behavior monitoring. Digital twin fleet management enhances these processes by creating virtual replicas of physical vehicles, enabling real-time data analysis and predictive maintenance for optimized performance.

The Evolution Toward Digital Solutions

Fleet management has traditionally relied on manual tracking and basic telematics to monitor vehicle usage, maintenance schedules, and driver behavior. The evolution toward digital twin fleet management integrates real-time data analytics, virtual simulations, and predictive maintenance to optimize operational efficiency and reduce downtime. This digital transformation enhances decision-making by providing a comprehensive, dynamic replica of the entire fleet, enabling proactive management and cost savings.

What is Traditional Fleet Management?

Traditional fleet management involves the coordination and oversight of vehicles using manual processes and basic software tools to track maintenance, fuel consumption, routing, and driver performance. It relies on scheduled inspections, physical odometer readings, and manual data entry, often leading to delays in identifying issues or inefficiencies. This conventional approach lacks real-time visibility and predictive analytics, limiting optimization and cost savings in vehicle operations.

Understanding Digital Twin Fleet Management

Digital Twin Fleet Management leverages real-time data synchronization between physical vehicles and their virtual counterparts, enabling predictive maintenance and optimized route planning. This advanced approach contrasts traditional Fleet Management by providing dynamic simulation capabilities that enhance operational efficiency and reduce downtime. Integrating IoT sensors and AI analytics, Digital Twin technology delivers precise insights into fleet performance, leading to cost savings and improved asset utilization.

Key Differences: Traditional vs Digital Twin Approaches

Fleet management relies on manual tracking and periodic data updates, often leading to delayed decision-making and limited predictive insights. Digital twin fleet management uses real-time data integration, advanced simulations, and AI-driven analytics to optimize vehicle performance, maintenance scheduling, and route planning. This digital approach enhances operational efficiency, reduces downtime, and enables proactive issue resolution compared to traditional fleet management methods.

Benefits of Digital Twin Fleet Management

Digital Twin Fleet Management enhances real-time monitoring and predictive maintenance by creating virtual replicas of physical vehicles, improving operational efficiency and reducing downtime significantly. It enables data-driven decision-making through continuous analysis of vehicle performance and environmental conditions, leading to optimized routing and fuel consumption. Integration with IoT sensors and AI algorithms facilitates proactive issue detection, asset utilization, and extended vehicle life cycles compared to traditional fleet management systems.

Challenges in Implementing Digital Twins

Challenges in implementing digital twin fleet management include high initial costs and the complexity of integrating real-time data from multiple sources such as GPS, sensors, and vehicle diagnostics. Ensuring data accuracy and cybersecurity protection poses significant hurdles for fleet operators. Furthermore, the need for skilled personnel to analyze predictive analytics and maintain digital twin models limits widespread adoption.

Real-Time Data Analytics and Predictive Maintenance

Fleet Management leverages GPS tracking and telematics to monitor vehicle location, fuel usage, and driver behavior, enabling operational efficiency through reactive maintenance. Digital Twin Fleet Management integrates real-time data analytics with virtual models of each vehicle, allowing dynamic simulation of performance and early detection of potential failures. Predictive maintenance is enhanced by continuous data input from sensors, reducing downtime and maintenance costs by anticipating issues before they occur.

Cost Implications and ROI Comparison

Traditional fleet management often incurs higher operational costs due to limited real-time data integration, resulting in reactive maintenance and suboptimal asset utilization. Digital twin fleet management leverages advanced simulation and predictive analytics to reduce downtime, optimize maintenance schedules, and improve fuel efficiency, significantly lowering total cost of ownership (TCO). ROI analysis indicates digital twin solutions deliver faster payback periods and enhanced long-term savings by enabling proactive decision-making and extending vehicle lifespan.

Future Trends in Fleet Technology

Fleet management is evolving with the integration of digital twin technology, enabling real-time simulation and predictive analytics of vehicle performance and maintenance needs. Digital twin fleet management leverages IoT sensors and AI algorithms to optimize route planning, reduce fuel consumption, and enhance asset utilization. Future trends point towards fully autonomous fleets interconnected through digital twins, driving efficiency, safety, and sustainability in transportation networks.

Related Important Terms

Telematics-Driven Fleet Optimization

Telematics-driven fleet optimization relies on real-time data collection to enhance route efficiency, fuel consumption, and vehicle maintenance in traditional fleet management, while digital twin fleet management creates a dynamic virtual replica of the fleet for predictive analytics and proactive decision-making. The integration of IoT sensors, GPS tracking, and AI algorithms in digital twin technology enables more precise monitoring and simulation of vehicle performance, reducing downtime and operational costs significantly.

Predictive Maintenance Algorithms

Fleet Management relies on traditional maintenance schedules and reactive repairs, often resulting in higher downtime and increased operational costs. Digital Twin Fleet Management leverages advanced predictive maintenance algorithms that analyze real-time sensor data, enabling early detection of potential failures and optimized maintenance planning to enhance vehicle uptime and reduce expenses.

Edge-Enabled Fleet Insights

Edge-enabled fleet insights in digital twin fleet management utilize real-time data processing at the source, significantly enhancing predictive maintenance and operational efficiency compared to traditional fleet management systems. Incorporating IoT sensors and advanced analytics, digital twins create dynamic replicas of physical vehicles, enabling immediate response to anomalies and optimized route planning through continuous, localized data analysis.

Digital Twin Vehicle Modeling

Digital Twin vehicle modeling in fleet management enables real-time simulation and analysis of vehicle performance, leading to predictive maintenance and optimized operational efficiency. This technology creates a virtual replica of each vehicle, allowing managers to monitor engine conditions, fuel consumption, and route efficiency with greater precision than traditional fleet management systems.

Real-Time Fleet Virtualization

Fleet management relies on traditional tracking systems for vehicle monitoring, while digital twin fleet management leverages real-time fleet virtualization to create dynamic virtual replicas of each asset, enhancing operational insights and predictive maintenance. Real-time data integration in digital twins enables proactive decision-making, reduces downtime, and optimizes route planning more effectively than conventional fleet management systems.

AI-Driven Asset Utilization

AI-driven asset utilization in Digital Twin Fleet Management leverages real-time data and predictive analytics to optimize vehicle performance, maintenance schedules, and route efficiency, significantly reducing operational costs. Traditional Fleet Management relies on historical data and manual monitoring, limiting its ability to dynamically adapt to changing conditions and maximize asset productivity.

Synthetic Sensor Data Simulation

Fleet management relies on real-time data collection from physical sensors to monitor vehicle performance and optimize operations. Digital twin fleet management enhances this by using synthetic sensor data simulation, enabling predictive maintenance and scenario testing without risking actual assets or disrupting service.

Connected Vehicle Digital Twins

Fleet management integrates vehicle tracking, maintenance, and driver performance to optimize operations, while digital twin fleet management leverages connected vehicle digital twins to create real-time virtual models that enhance predictive maintenance and operational efficiency. Connected vehicle digital twins provide continuous data synchronization, enabling precise simulations and proactive decision-making for reducing downtime and operational costs.

Mobility-as-a-Service (MaaS) Fleet Integration

Fleet management traditionally focuses on vehicle maintenance, route planning, and driver coordination, whereas digital twin fleet management leverages real-time data simulation and predictive analytics to optimize Mobility-as-a-Service (MaaS) fleet integration. Incorporating digital twins enhances operational efficiency and customer experience by enabling dynamic route adjustments and seamless resource allocation across multiple transportation modes.

Remote Diagnostics via Digital Twin Fleet

Digital Twin Fleet Management enhances traditional fleet operations by enabling real-time remote diagnostics through virtual replicas of vehicles, allowing precise monitoring of performance, predictive maintenance, and early fault detection. This technology reduces downtime and operational costs by providing accurate, continuous data streams that traditional fleet management systems cannot deliver remotely.

Fleet Management vs Digital Twin Fleet Management Infographic

industrydif.com

industrydif.com