RF scanning utilizes handheld devices to quickly capture barcodes, ensuring accurate inventory tracking and efficient item retrieval in warehousing environments. Vision picking employs head-mounted displays to provide real-time visual instructions, enhancing worker productivity by reducing errors and speeding up order fulfillment. Both technologies streamline warehouse operations but differ in interface and interaction methods, allowing businesses to choose based on their specific needs.

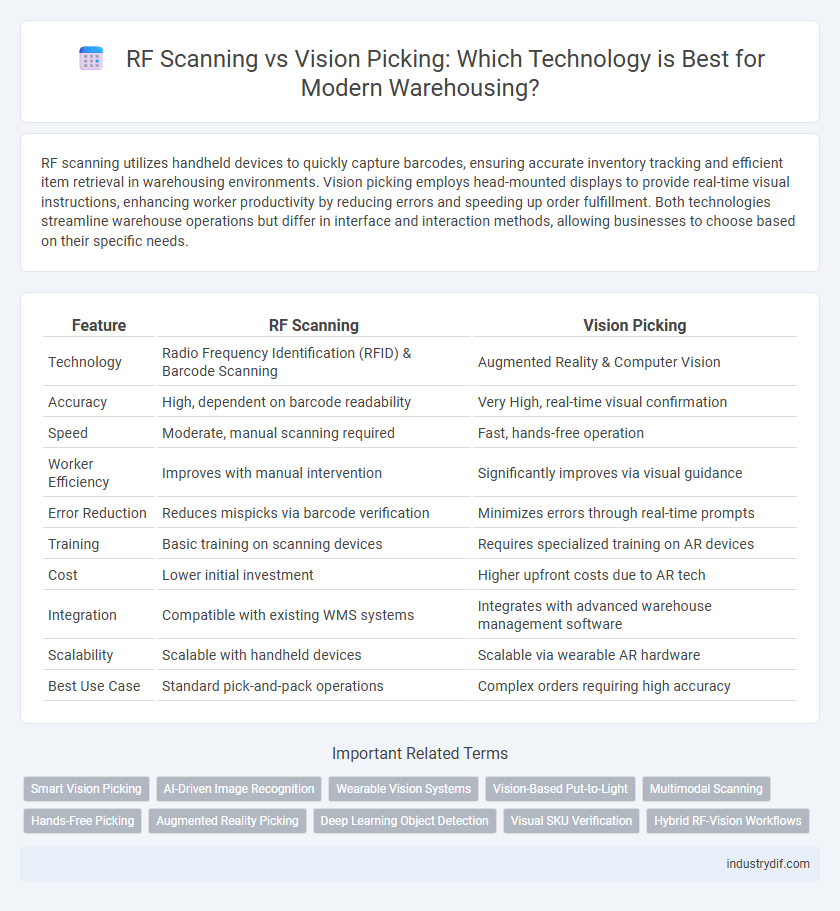

Table of Comparison

| Feature | RF Scanning | Vision Picking |

|---|---|---|

| Technology | Radio Frequency Identification (RFID) & Barcode Scanning | Augmented Reality & Computer Vision |

| Accuracy | High, dependent on barcode readability | Very High, real-time visual confirmation |

| Speed | Moderate, manual scanning required | Fast, hands-free operation |

| Worker Efficiency | Improves with manual intervention | Significantly improves via visual guidance |

| Error Reduction | Reduces mispicks via barcode verification | Minimizes errors through real-time prompts |

| Training | Basic training on scanning devices | Requires specialized training on AR devices |

| Cost | Lower initial investment | Higher upfront costs due to AR tech |

| Integration | Compatible with existing WMS systems | Integrates with advanced warehouse management software |

| Scalability | Scalable with handheld devices | Scalable via wearable AR hardware |

| Best Use Case | Standard pick-and-pack operations | Complex orders requiring high accuracy |

Introduction to RF Scanning and Vision Picking

RF scanning utilizes radio frequency technology to enable warehouse workers to scan barcodes and update inventory data in real-time, improving accuracy and efficiency in order processing. Vision picking employs augmented reality glasses or headsets to guide operators through picking tasks with visual cues, reducing errors and increasing productivity by overlaying digital information on the physical environment. Both technologies revolutionize warehouse operations by enhancing data capture and task execution but differ in their interaction methods and technological complexity.

How RF Scanning Works in Warehousing

RF scanning in warehousing operates by using handheld or fixed radio frequency (RF) devices to scan barcodes on inventory items, enabling real-time data capture and inventory tracking. These devices communicate with a warehouse management system (WMS) to update stock levels, location, and status instantly, enhancing accuracy and efficiency in order fulfillment. The scanning process reduces human errors and accelerates tasks such as receiving, picking, packing, and shipping by automating data entry and inventory verification.

Understanding Vision Picking Technology

Vision picking technology utilizes advanced head-mounted displays and augmented reality to guide warehouse workers through order fulfillment processes with precise visual cues. This system enhances accuracy and efficiency by projecting pick locations and item information directly into the worker's field of view, reducing reliance on handheld RF scanners. By integrating real-time data and spatial recognition, vision picking optimizes workflow and minimizes errors in high-volume warehousing operations.

Key Differences Between RF Scanning and Vision Picking

RF scanning relies on handheld barcode scanners to capture item data quickly, ensuring accurate inventory tracking through explicit barcode recognition. Vision picking employs wearable smart glasses with computer vision technology, allowing workers to receive real-time visual instructions and hands-free item identification. Unlike RF scanning's manual scanning process, vision picking enhances efficiency and reduces errors by integrating augmented reality for intuitive workflows in complex warehousing environments.

Accuracy and Efficiency: RF Scanning vs Vision Picking

RF scanning systems deliver high accuracy in inventory tracking by enabling precise barcode or RFID tag reads, reducing picking errors and minimizing misplacements. Vision picking leverages augmented reality and real-time visual guidance to enhance picker efficiency and accuracy, allowing faster identification of items and locations without manual scanning. Both technologies improve warehouse operations, but vision picking often surpasses RF scanning in speed and error reduction by providing intuitive, hands-free instructions.

Implementation Challenges in Warehousing

RF scanning implementation in warehousing demands significant investment in handheld devices and network infrastructure, often facing challenges with device durability and signal interference in large facilities. Vision picking systems require integration of advanced AR glasses or headsets, presenting difficulties in employee training and adapting workflows to new technology. Both technologies necessitate robust IT support and change management strategies to minimize operational disruption during deployment.

Cost Considerations and Return on Investment

RF scanning systems typically require lower upfront investment compared to advanced vision picking technologies, making them more accessible for small to mid-sized warehouses. Vision picking, while involving higher initial costs due to sophisticated hardware and software integration, often delivers greater accuracy and efficiency gains that translate to faster return on investment in high-volume operations. Analyzing total cost of ownership, including maintenance and training, is crucial to determine the most cost-effective solution tailored to specific warehousing needs.

Impact on Workforce and Training Needs

RF scanning streamlines warehouse operations by enabling workers to quickly and accurately scan barcodes, reducing errors and minimizing training time due to its straightforward interface. Vision picking, driven by augmented reality and wearable devices, enhances worker productivity by providing hands-free, real-time visual instructions but requires more extensive training to master the technology and adapt to the new workflow. The choice between RF scanning and vision picking significantly impacts workforce adaptability, with RF scanning favoring rapid onboarding and vision picking demanding higher initial investment in employee training and skill development.

Scalability and Future-Proofing Your Warehouse

RF scanning technology offers scalable solutions with robust barcode reading capabilities that integrate easily into existing warehouse management systems, ensuring long-term operational continuity. Vision picking systems leverage augmented reality and machine learning for flexible adaptations to complex tasks, promoting future-proof workflows as warehouse demands evolve. Investing in either technology enhances scalability, but vision picking's advanced data analytics provides greater potential for innovation and process optimization in expanding warehouses.

Choosing the Right Picking Technology for Your Operation

RF scanning offers precise inventory tracking through barcode or RFID data capture, enhancing real-time accuracy in warehouse operations. Vision picking technology leverages augmented reality and wearable devices to provide visual cues, improving picker efficiency and reducing error rates. Selecting the right picking technology depends on operation scale, picking complexity, and integration capabilities with existing warehouse management systems (WMS).

Related Important Terms

Smart Vision Picking

Smart Vision Picking integrates advanced image recognition and AI algorithms to enhance accuracy and efficiency in warehouse order fulfillment compared to traditional RF scanning methods. This technology reduces errors, speeds up picking processes, and provides real-time inventory data, optimizing overall warehouse productivity and operational insight.

AI-Driven Image Recognition

AI-driven image recognition in warehousing enhances vision picking by accurately identifying and verifying products in real-time, reducing errors and increasing picking speed compared to traditional RF scanning, which relies on barcode or RFID data capture. Incorporating advanced machine learning algorithms allows vision systems to adapt to varied lighting and packaging conditions, optimizing inventory accuracy and operational efficiency.

Wearable Vision Systems

Wearable vision systems in warehousing enhance accuracy and efficiency by providing hands-free, real-time visual guidance compared to traditional RF scanning, which requires handheld devices and can slow down picking processes. These advanced systems improve worker productivity and reduce errors by integrating augmented reality with voice commands and barcode recognition directly in the operator's field of view.

Vision-Based Put-to-Light

Vision-based put-to-light systems enhance warehouse accuracy by using cameras and smart displays to guide operators in placing items correctly, reducing errors compared to traditional RF scanning methods. These systems improve pick-and-put efficiency by providing real-time visual confirmation and dynamic location updates, leading to optimized inventory management and faster order fulfillment.

Multimodal Scanning

Multimodal scanning combines RF scanning and vision picking technologies to enhance accuracy and efficiency in warehousing operations, enabling real-time data capture through barcode scanning and visual recognition simultaneously. This integration reduces errors, improves inventory management, and accelerates order fulfillment by leveraging both radio frequency and computer vision capabilities for comprehensive item identification.

Hands-Free Picking

RF scanning enables hands-free picking by using wearable devices such as headsets or rings that allow workers to scan barcodes without using their hands, significantly increasing efficiency and accuracy in warehousing operations. Vision picking leverages augmented reality glasses to display picking information directly in the worker's field of view, eliminating the need for handheld scanners and enhancing productivity through seamless hands-free interaction.

Augmented Reality Picking

Augmented Reality Picking leverages AR glasses to overlay digital picking instructions directly onto the warehouse environment, significantly improving accuracy and speed compared to traditional RF scanning methods. This technology reduces errors by providing real-time visual guidance and hands-free operation, streamlining order fulfillment processes in modern warehouses.

Deep Learning Object Detection

Deep learning object detection enhances vision picking by accurately identifying and locating items in complex warehouse environments, reducing errors and improving efficiency compared to traditional RF scanning, which relies on manual barcode scanning. Vision picking leverages convolutional neural networks to automate item recognition, enabling faster order fulfillment and real-time inventory updates without the need for direct line-of-sight scanning.

Visual SKU Verification

Visual SKU verification using vision picking technology enhances accuracy by automatically matching scanned images of products against stored SKU data, reducing human errors associated with manual RF scanning. This method accelerates item identification and confirmation processes in warehouses, improving inventory accuracy and operational efficiency.

Hybrid RF-Vision Workflows

Hybrid RF-vision workflows in warehousing combine the accuracy of Vision Picking with the real-time data capture of RF Scanning to optimize order fulfillment. This integrated approach enhances inventory accuracy and accelerates picking speed by leveraging barcode data and visual confirmation, reducing errors and boosting operational efficiency.

RF Scanning vs Vision Picking Infographic

industrydif.com

industrydif.com