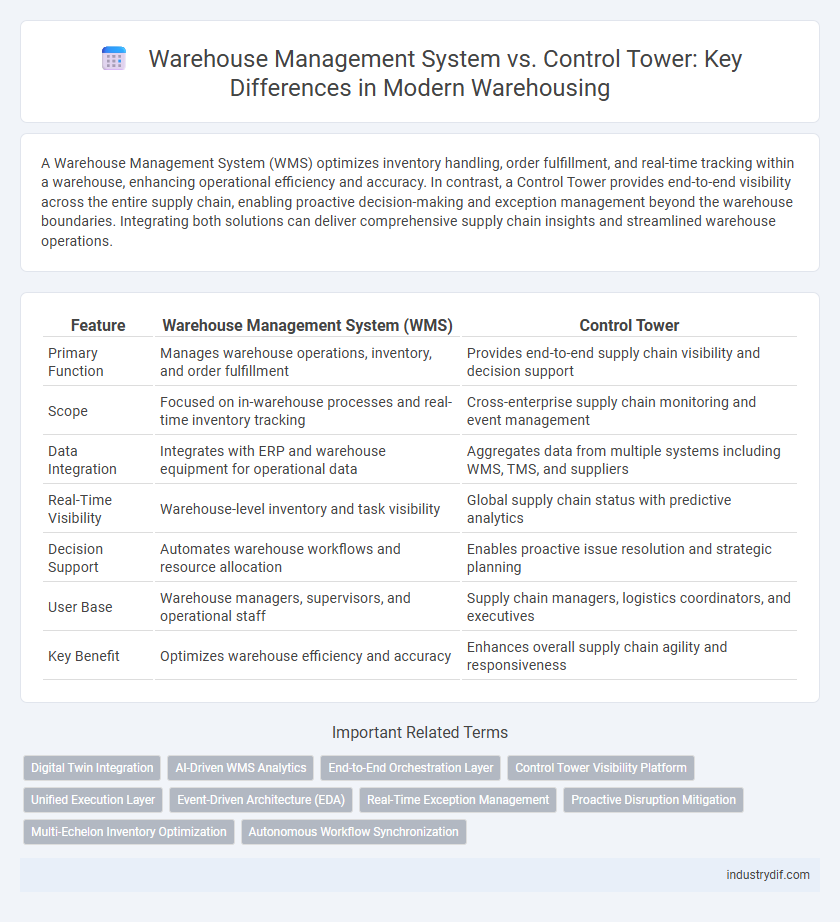

A Warehouse Management System (WMS) optimizes inventory handling, order fulfillment, and real-time tracking within a warehouse, enhancing operational efficiency and accuracy. In contrast, a Control Tower provides end-to-end visibility across the entire supply chain, enabling proactive decision-making and exception management beyond the warehouse boundaries. Integrating both solutions can deliver comprehensive supply chain insights and streamlined warehouse operations.

Table of Comparison

| Feature | Warehouse Management System (WMS) | Control Tower |

|---|---|---|

| Primary Function | Manages warehouse operations, inventory, and order fulfillment | Provides end-to-end supply chain visibility and decision support |

| Scope | Focused on in-warehouse processes and real-time inventory tracking | Cross-enterprise supply chain monitoring and event management |

| Data Integration | Integrates with ERP and warehouse equipment for operational data | Aggregates data from multiple systems including WMS, TMS, and suppliers |

| Real-Time Visibility | Warehouse-level inventory and task visibility | Global supply chain status with predictive analytics |

| Decision Support | Automates warehouse workflows and resource allocation | Enables proactive issue resolution and strategic planning |

| User Base | Warehouse managers, supervisors, and operational staff | Supply chain managers, logistics coordinators, and executives |

| Key Benefit | Optimizes warehouse efficiency and accuracy | Enhances overall supply chain agility and responsiveness |

Introduction to Warehouse Management Systems (WMS)

A Warehouse Management System (WMS) is a software solution designed to optimize warehouse operations including inventory tracking, order fulfillment, and labor management. It enables real-time visibility of stock levels and streamlines processes to reduce errors and improve overall efficiency. Unlike a Control Tower, which provides end-to-end supply chain oversight, a WMS focuses specifically on managing internal warehouse activities.

Understanding Control Tower Solutions in Warehousing

Control Tower solutions in warehousing provide real-time visibility and centralized oversight of inventory, shipments, and supply chain activities, enabling dynamic decision-making and proactive issue resolution. Unlike traditional Warehouse Management Systems (WMS), which focus primarily on operational execution within warehouse boundaries, Control Towers integrate data across multiple logistics nodes, enhancing end-to-end supply chain transparency. This integration supports predictive analytics and collaborative workflows, crucial for optimizing inventory levels and improving overall supply chain efficiency.

Core Functions of a Warehouse Management System

A Warehouse Management System (WMS) primarily focuses on optimizing inventory control, order fulfillment, and real-time tracking of goods within the warehouse. Core functions include receiving, put-away, picking, packing, and shipping processes, ensuring accuracy and efficiency at each stage. Unlike a Control Tower, which offers end-to-end supply chain visibility, a WMS is specialized in managing day-to-day operational workflows inside the warehouse environment.

Key Features of a Control Tower in Logistics

Control Towers in logistics offer real-time visibility across the supply chain, enhancing decision-making through centralized data aggregation and advanced analytics. Key features include proactive exception management, predictive insights using AI and machine learning, and seamless integration with multiple transport and warehouse management systems. These capabilities enable dynamic route optimization, improved inventory accuracy, and accelerated response times compared to traditional Warehouse Management Systems.

WMS vs Control Tower: Functional Comparison

Warehouse Management Systems (WMS) specialize in optimizing inventory tracking, order fulfillment, and labor management within the warehouse, ensuring real-time visibility of stock levels and workflow efficiency. Control Towers provide a broader, end-to-end supply chain oversight, integrating data across multiple warehouses, transportation, and suppliers for predictive analytics and proactive decision-making. While WMS focuses on operational execution inside the warehouse, Control Towers emphasize strategic coordination and risk management across the entire logistics network.

Integration Capabilities: WMS and Control Tower

Warehouse Management Systems (WMS) offer deep integration with physical warehouse operations, including inventory tracking, order fulfillment, and labor management, enabling real-time updates within the facility. Control Towers provide broader supply chain visibility by aggregating data across multiple systems and partners, facilitating proactive decision-making and end-to-end tracking. Combining WMS with Control Tower solutions enhances integration capabilities by bridging execution-level data with strategic oversight, driving operational efficiency and supply chain responsiveness.

Data Visibility and Real-Time Insights

Warehouse Management Systems (WMS) provide granular data visibility on inventory levels, order status, and location within the warehouse, optimizing daily operations and resource allocation. Control Towers offer a broader, end-to-end view of the supply chain by integrating data from multiple systems, delivering real-time insights for proactive decision-making and risk mitigation. Combining WMS with Control Tower capabilities enhances operational transparency and responsiveness across warehouse and supply chain networks.

Scalability and Flexibility in Modern Warehousing

Warehouse Management Systems (WMS) offer scalable solutions tailored to operational workflows, providing flexibility in inventory tracking and order processing within a single facility. Control Towers deliver broader visibility by integrating data across multiple warehouses and supply chain partners, enhancing real-time decision-making and adaptability to dynamic market demands. The combination of a WMS's operational depth with Control Tower's strategic oversight enables modern warehousing to scale efficiently while maintaining responsive and flexible logistics management.

Choosing the Right Solution: Factors to Consider

Warehouse Management System (WMS) optimizes inventory tracking, order fulfillment, and labor management within the warehouse, while Control Towers provide end-to-end supply chain visibility and real-time decision-making across multiple locations. Key factors to consider include the scale of operations, integration complexity, real-time data needs, and the desired level of control from warehouse-level tasks to overall logistics coordination. Businesses should evaluate operational scope, existing technology infrastructure, and strategic goals to choose between WMS's detailed warehouse optimization and Control Tower's broader supply chain oversight.

Future Trends: Evolving Roles of WMS and Control Tower

Warehouse Management Systems (WMS) increasingly integrate AI and IoT technologies to enhance inventory accuracy, automate workflows, and provide real-time insights for operational efficiency. Control Towers evolve to offer end-to-end supply chain visibility, leveraging predictive analytics and machine learning to proactively address disruptions and optimize decision-making. The future landscape emphasizes seamless collaboration between WMS and Control Towers, driving smarter, more agile warehousing and supply chain ecosystems.

Related Important Terms

Digital Twin Integration

Warehouse Management Systems (WMS) optimize on-site inventory tracking and order fulfillment, while Control Towers provide real-time visibility across the entire supply chain. Integrating digital twin technology enhances both by enabling dynamic simulation of warehouse operations and supply chain scenarios for proactive decision-making and risk mitigation.

AI-Driven WMS Analytics

AI-driven Warehouse Management System (WMS) analytics leverage machine learning algorithms to optimize inventory accuracy, enhance real-time demand forecasting, and streamline order fulfillment processes. Control Towers provide end-to-end supply chain visibility but lack the granular, AI-powered operational insights that advanced WMS analytics deliver for warehouse efficiency and decision-making.

End-to-End Orchestration Layer

Warehouse Management Systems (WMS) primarily focus on optimizing warehouse-level operations such as inventory tracking, picking, and receiving, while Control Towers provide an end-to-end orchestration layer that integrates multiple supply chain functions for real-time visibility and proactive decision-making. The Control Tower's comprehensive platform enables seamless coordination across suppliers, warehouses, transportation, and customers, enhancing overall supply chain agility beyond the scope of traditional WMS capabilities.

Control Tower Visibility Platform

Control Tower Visibility Platforms provide real-time, end-to-end supply chain insights by integrating data from warehouse management systems (WMS) and other logistics nodes, enabling proactive issue resolution and enhanced decision-making. Unlike traditional WMS that focus on internal warehouse operations, Control Towers offer a holistic view of inventory, shipments, and transportation across multiple facilities for optimized supply chain performance.

Unified Execution Layer

A Warehouse Management System (WMS) streamlines inventory tracking, order fulfillment, and labor management within warehouses, while a Control Tower offers centralized visibility and orchestration across multiple supply chain nodes. The Unified Execution Layer integrates WMS functions with Control Tower capabilities to provide real-time data synchronization, enhanced operational control, and seamless decision-making across the entire supply chain ecosystem.

Event-Driven Architecture (EDA)

Warehouse Management Systems (WMS) optimize inventory and order fulfillment through real-time tracking and task automation, while Control Towers leverage Event-Driven Architecture (EDA) to provide dynamic visibility and proactive decision-making across the entire supply chain. EDA enables Control Towers to instantly process and respond to warehouse events, improving responsiveness and operational agility beyond the transactional focus of traditional WMS.

Real-Time Exception Management

Warehouse Management Systems (WMS) enable real-time exception management by tracking inventory movements and flagging discrepancies directly within warehouse operations; Control Towers enhance this by providing a centralized visibility layer across the entire supply chain, facilitating proactive identification and resolution of cross-network exceptions. Integrating WMS with Control Tower platforms optimizes real-time exception handling through comprehensive data synchronization and actionable insights, resulting in improved response times and operational efficiency.

Proactive Disruption Mitigation

A Warehouse Management System (WMS) enables proactive disruption mitigation by providing real-time inventory tracking, automated task prioritization, and seamless resource allocation to quickly identify and resolve operational bottlenecks. Control Towers enhance this capability through end-to-end supply chain visibility, enabling predictive analytics and scenario planning to anticipate and mitigate disruptions before they impact warehouse operations.

Multi-Echelon Inventory Optimization

Warehouse Management Systems (WMS) primarily focus on real-time inventory tracking and operational efficiency within individual warehouse locations, while Control Towers provide a holistic, multi-echelon inventory optimization by integrating data across the entire supply chain network. Leveraging advanced analytics and AI, Control Towers enable dynamic decision-making for stock allocation, demand forecasting, and order fulfillment across multiple warehouses, surpassing the localized scope of traditional WMS.

Autonomous Workflow Synchronization

Warehouse Management Systems (WMS) optimize inventory tracking and order fulfillment within facility boundaries, while Control Towers enable Autonomous Workflow Synchronization by overseeing cross-functional supply chain activities in real-time. Integrating Control Tower capabilities with WMS ensures seamless coordination across warehouses, transportation, and suppliers, driving operational agility and enhanced visibility.

Warehouse Management System vs Control Tower Infographic

industrydif.com

industrydif.com