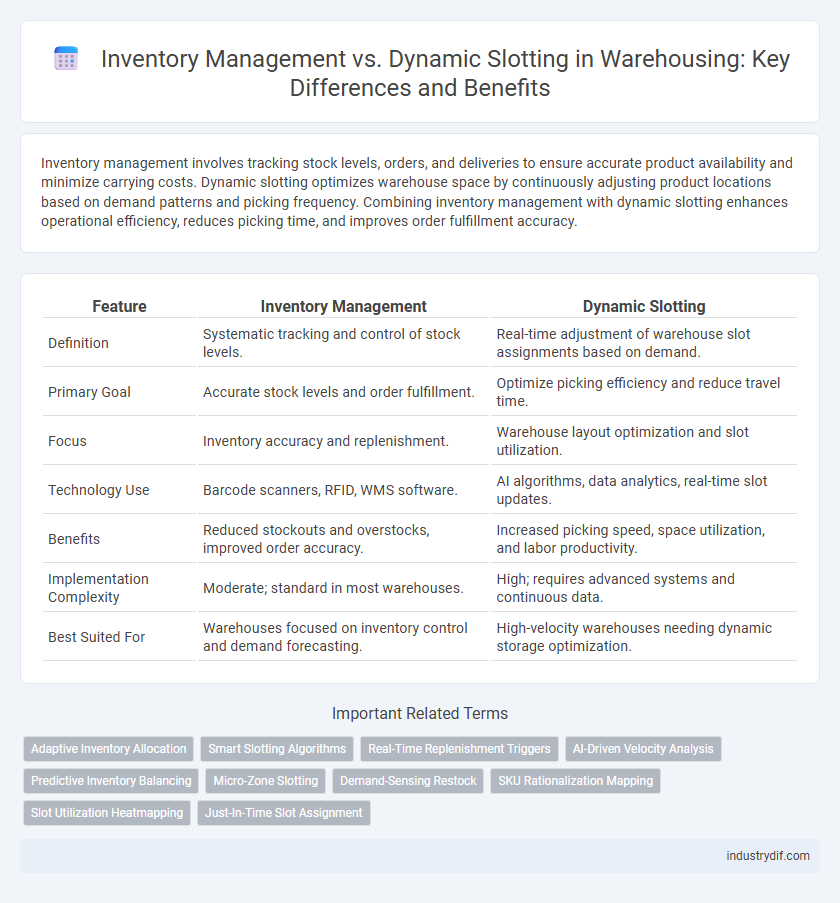

Inventory management involves tracking stock levels, orders, and deliveries to ensure accurate product availability and minimize carrying costs. Dynamic slotting optimizes warehouse space by continuously adjusting product locations based on demand patterns and picking frequency. Combining inventory management with dynamic slotting enhances operational efficiency, reduces picking time, and improves order fulfillment accuracy.

Table of Comparison

| Feature | Inventory Management | Dynamic Slotting |

|---|---|---|

| Definition | Systematic tracking and control of stock levels. | Real-time adjustment of warehouse slot assignments based on demand. |

| Primary Goal | Accurate stock levels and order fulfillment. | Optimize picking efficiency and reduce travel time. |

| Focus | Inventory accuracy and replenishment. | Warehouse layout optimization and slot utilization. |

| Technology Use | Barcode scanners, RFID, WMS software. | AI algorithms, data analytics, real-time slot updates. |

| Benefits | Reduced stockouts and overstocks, improved order accuracy. | Increased picking speed, space utilization, and labor productivity. |

| Implementation Complexity | Moderate; standard in most warehouses. | High; requires advanced systems and continuous data. |

| Best Suited For | Warehouses focused on inventory control and demand forecasting. | High-velocity warehouses needing dynamic storage optimization. |

Introduction to Inventory Management and Dynamic Slotting

Inventory management in warehousing involves tracking, controlling, and optimizing stock levels to ensure product availability while minimizing holding costs. Dynamic slotting enhances traditional inventory management by continuously adjusting the placement of products based on real-time demand patterns and warehouse activity. Combining inventory management with dynamic slotting improves storage efficiency and accelerates order fulfillment processes.

Defining Inventory Management in Warehousing

Inventory management in warehousing involves systematically tracking, storing, and controlling stock levels to optimize supply chain efficiency and reduce carrying costs. It encompasses accurate demand forecasting, order replenishment, and real-time visibility of inventory status to prevent stockouts and overstock situations. Effective inventory management underpins dynamic slotting by providing the essential data required to rearrange products based on factors like picking frequency and seasonal demand shifts.

Understanding Dynamic Slotting Techniques

Dynamic slotting techniques optimize warehouse inventory placement by continuously analyzing product demand, size, and turnover rates to assign storage locations that maximize picking efficiency. Unlike static inventory management, dynamic slotting adapts to real-time data, reducing travel time and improving space utilization. This method leverages algorithms and automation to enhance order accuracy and throughput in modern warehousing operations.

Key Differences Between Inventory Management and Dynamic Slotting

Inventory management focuses on tracking stock levels, orders, and replenishment to maintain optimal inventory accuracy and availability. Dynamic slotting optimizes the placement of products within the warehouse based on factors such as demand variability, seasonality, and picking velocity to enhance picking efficiency. The key difference lies in inventory management's emphasis on overall stock control, whereas dynamic slotting targets spatial organization to reduce travel time and improve order fulfillment speed.

Benefits of Effective Inventory Management

Effective inventory management reduces stockouts and overstock situations, enhancing order fulfillment accuracy and customer satisfaction. It optimizes storage space utilization and streamlines warehouse operations, leading to lower holding costs and increased operational efficiency. Integrating dynamic slotting further refines product placement based on demand patterns, accelerating picking processes and minimizing labor expenses.

Advantages of Implementing Dynamic Slotting

Dynamic slotting optimizes warehouse space utilization by continuously adjusting product locations based on real-time demand and inventory turnover, leading to faster picking times and reduced labor costs. Unlike static inventory management, dynamic slotting enhances order accuracy and decreases stockouts by prioritizing high-movement SKUs in accessible zones. Implementing dynamic slotting results in improved warehouse efficiency and increased throughput, directly contributing to cost savings and customer satisfaction.

Challenges and Limitations of Each Approach

Inventory management often faces challenges such as inaccurate demand forecasting and stock discrepancies, leading to inefficient space utilization and increased holding costs. Dynamic slotting, while improving picking efficiency by frequently reorganizing inventory locations, encounters limitations including higher labor intensity and system complexity, which may result in operational disruptions. Both approaches require advanced data analytics and real-time tracking to mitigate errors and optimize warehouse performance effectively.

Integrating Inventory Management with Dynamic Slotting Systems

Integrating inventory management with dynamic slotting systems enhances warehouse efficiency by optimizing product placement based on real-time demand and inventory levels. This synergy reduces picking time and minimizes errors, leading to improved order accuracy and faster fulfillment cycles. Advanced analytics and IoT technologies enable continuous adjustment of slotting strategies, maximizing space utilization and operational productivity.

Technology Solutions for Optimized Warehouse Operations

Inventory management leverages barcode scanning, RFID technology, and warehouse management systems (WMS) to track stock levels, reduce errors, and streamline order fulfillment. Dynamic slotting uses real-time data analytics and machine learning algorithms to optimize product placement based on demand patterns, reducing travel time and increasing picking efficiency. Integrating advanced technology solutions into both inventory management and dynamic slotting enhances accuracy, improves space utilization, and accelerates overall warehouse operations.

Choosing the Right Strategy for Your Warehouse

Inventory management ensures accurate tracking and replenishment of stock, reducing errors and stockouts to optimize warehouse efficiency. Dynamic slotting enhances picking speed by periodically reorganizing inventory locations based on demand patterns, improving space utilization and order fulfillment times. Selecting the right strategy depends on warehouse size, product variety, and order complexity to balance operational costs and service levels.

Related Important Terms

Adaptive Inventory Allocation

Adaptive inventory allocation enhances warehouse efficiency by dynamically adjusting stock placement based on real-time demand patterns and product velocity. This method surpasses traditional inventory management by optimizing space utilization and reducing picking times through intelligent slotting decisions tailored to fluctuating inventory flows.

Smart Slotting Algorithms

Smart slotting algorithms enhance inventory management by dynamically optimizing product placement based on real-time demand, turnover rates, and product characteristics. These algorithms reduce picking time and increase warehouse efficiency by continuously adapting slot assignments to current inventory patterns and order flows.

Real-Time Replenishment Triggers

Inventory management relies on fixed replenishment schedules based on historical data, while dynamic slotting utilizes real-time replenishment triggers driven by current order demand and stock levels. Real-time data integration in dynamic slotting optimizes warehouse space utilization and reduces stockouts by promptly adjusting inventory allocation.

AI-Driven Velocity Analysis

AI-driven velocity analysis enhances inventory management by accurately predicting product demand patterns, enabling dynamic slotting to optimize warehouse space and reduce picking times. This integration increases operational efficiency by aligning inventory placement with real-time sales velocity, minimizing handling costs and improving order fulfillment speed.

Predictive Inventory Balancing

Predictive inventory balancing leverages dynamic slotting to optimize warehouse storage by continuously adjusting product locations based on demand forecasts, reducing picking time and stockouts. Unlike traditional inventory management, this approach uses real-time data analytics to balance stock levels proactively, enhancing overall operational efficiency.

Micro-Zone Slotting

Inventory Management optimizes stock levels and turnover rates to enhance warehouse efficiency, while Dynamic Slotting, particularly Micro-Zone Slotting, strategically assigns products to specific small zones based on real-time demand and picking patterns to reduce travel time and increase order accuracy. Micro-Zone Slotting leverages data analytics and automation to adapt slot placements dynamically, improving space utilization and accelerating picking processes in high-velocity warehouses.

Demand-Sensing Restock

Demand-sensing restock in inventory management uses real-time data analytics to predict product demand, optimizing stock levels while reducing excess inventory and stockouts. Dynamic slotting complements this approach by continuously reallocating storage locations based on demand patterns, enhancing warehouse efficiency and minimizing picking times.

SKU Rationalization Mapping

Inventory management optimizes stock levels and order accuracy, while dynamic slotting enhances storage efficiency by adjusting SKU placements based on real-time demand and inventory turnover. SKU rationalization mapping integrates both approaches by analyzing product performance and demand patterns to strategically allocate warehouse space, reducing holding costs and improving picking speed.

Slot Utilization Heatmapping

Inventory management relies on static slot allocation methods that often lead to inefficient space usage, while dynamic slotting enhances slot utilization through real-time heatmapping of inventory movements and turnover rates. Slot utilization heatmapping leverages data analytics to identify high-traffic zones and optimize product placement, reducing travel time and increasing warehouse throughput.

Just-In-Time Slot Assignment

Just-In-Time Slot Assignment enhances inventory management by dynamically allocating warehouse locations based on real-time demand and item velocity, reducing picking times and optimizing space utilization. This approach contrasts with static slotting by continuously adjusting slot assignments to improve order accuracy and operational efficiency.

Inventory Management vs Dynamic Slotting Infographic

industrydif.com

industrydif.com