Conventional warehousing relies on physical storage facilities with fixed capacities and significant overhead costs, requiring manual inventory management and maintenance. Cloud warehousing offers scalable, flexible data storage solutions accessed remotely, enabling real-time data analytics and seamless integration with supply chain systems. The shift to cloud warehousing enhances operational efficiency, reduces IT infrastructure expenses, and supports data-driven decision-making in modern logistics.

Table of Comparison

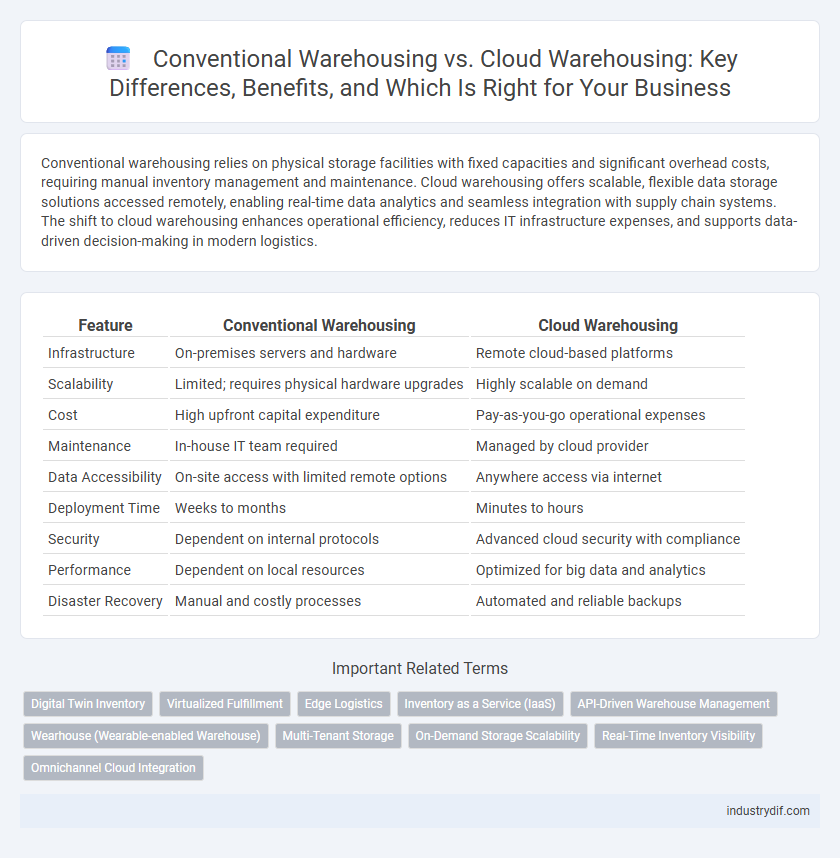

| Feature | Conventional Warehousing | Cloud Warehousing |

|---|---|---|

| Infrastructure | On-premises servers and hardware | Remote cloud-based platforms |

| Scalability | Limited; requires physical hardware upgrades | Highly scalable on demand |

| Cost | High upfront capital expenditure | Pay-as-you-go operational expenses |

| Maintenance | In-house IT team required | Managed by cloud provider |

| Data Accessibility | On-site access with limited remote options | Anywhere access via internet |

| Deployment Time | Weeks to months | Minutes to hours |

| Security | Dependent on internal protocols | Advanced cloud security with compliance |

| Performance | Dependent on local resources | Optimized for big data and analytics |

| Disaster Recovery | Manual and costly processes | Automated and reliable backups |

Introduction to Conventional Warehousing and Cloud Warehousing

Conventional warehousing involves physical storage facilities where goods are stored in fixed locations, requiring significant capital investment and manual inventory management. Cloud warehousing leverages cloud computing technology to provide scalable, flexible, and real-time data access, enabling businesses to manage inventory digitally without extensive on-site infrastructure. The integration of cloud platforms enhances data synchronization, reduces operational costs, and supports advanced analytics for optimized supply chain management.

Core Features of Conventional Warehousing

Conventional warehousing involves physical storage facilities with fixed infrastructure, offering controlled environments for inventory management and easy access to goods. Key features include on-site security, manual tracking systems, and predictable maintenance costs tied to the physical space. This model supports direct handling of materials but often lacks the scalability and remote data accessibility inherent in cloud warehousing solutions.

Key Components of Cloud Warehousing

Cloud warehousing leverages scalable storage, elastic compute resources, and advanced data integration tools to enable real-time analytics and seamless data accessibility. Key components include automated data ingestion pipelines, cloud-native storage solutions optimized for big data, and distributed computing frameworks that support complex queries. These elements ensure enhanced flexibility, cost efficiency, and rapid deployment compared to conventional warehousing systems.

Technology Integration in Warehousing

Conventional warehousing relies heavily on manual processes and legacy IT systems, limiting real-time data accessibility and automation capabilities. Cloud warehousing leverages advanced technologies such as IoT, AI, and machine learning integrated through cloud platforms, enabling scalable storage, real-time inventory tracking, and predictive analytics. This technological integration enhances operational efficiency, reduces errors, and supports dynamic demand-driven supply chain management.

Scalability Comparison: Traditional vs Cloud

Conventional warehousing relies on fixed physical infrastructure, limiting scalability and requiring significant capital investment for expansion. Cloud warehousing offers dynamic scalability with flexible resource allocation, enabling businesses to adjust storage capacity and computing power on demand. This agility allows cloud warehouses to handle fluctuating data volumes efficiently, reducing operational costs compared to traditional models.

Cost Implications and ROI Analysis

Conventional warehousing incurs high fixed costs related to physical infrastructure, maintenance, and labor, leading to significant upfront capital investment and ongoing operational expenses. Cloud warehousing offers scalable, pay-as-you-go pricing models that reduce capital expenditure and enable businesses to align expenses directly with data usage and storage needs, enhancing cost efficiency. ROI analysis reveals that cloud warehousing delivers faster returns through flexible scalability, reduced downtime, and lower total cost of ownership compared to traditional warehousing methods.

Data Security and Compliance Factors

Conventional warehousing relies heavily on on-premises infrastructure, which demands rigorous physical security measures and internal compliance protocols to protect sensitive data. Cloud warehousing offers advanced encryption, scalable access controls, and continuous monitoring, enhancing data security while ensuring compliance with industry standards such as GDPR, HIPAA, and SOC 2. Enterprise adoption of cloud warehousing solutions accelerates audit readiness and reduces risks associated with data breaches through automated compliance management features.

Operational Efficiency and Workflow Automation

Conventional warehousing relies heavily on manual processes, leading to slower operational efficiency and increased human error, whereas cloud warehousing leverages real-time data integration and advanced automation tools to streamline workflows and reduce delays. Cloud-based systems enable dynamic inventory management, automated order processing, and seamless scalability, significantly enhancing overall productivity. Operational metrics show that cloud warehousing can improve accuracy rates by up to 30% and reduce order fulfillment times by 40% compared to traditional methods.

Challenges and Limitations of Each Model

Conventional warehousing faces challenges such as high infrastructure costs, limited scalability, and complex maintenance requirements, which hinder operational flexibility and responsiveness. Cloud warehousing overcomes these issues by offering scalable storage and seamless data integration but may encounter limitations in data security concerns and dependence on reliable internet connectivity. Both models require careful consideration of cost, control, and accessibility to determine the optimal warehousing strategy for business needs.

Future Trends in Warehousing Solutions

Conventional warehousing relies on physical storage spaces limiting scalability and real-time data access, while cloud warehousing leverages cloud computing to enable flexible, scalable, and data-driven inventory management. Future trends in warehousing highlight the integration of AI, IoT, and advanced analytics within cloud warehouses to optimize supply chain visibility and automate inventory forecasting. Embracing cloud-based warehousing solutions drives operational efficiency, reduces costs, and enhances responsiveness to dynamic market demands.

Related Important Terms

Digital Twin Inventory

Conventional warehousing relies on physical storage and manual inventory processes, which can lead to inefficiencies and delayed data updates, whereas cloud warehousing integrates digital twin inventory technology to provide real-time, accurate virtual replicas of stock levels and warehouse operations. This digital twin inventory enables advanced analytics, predictive maintenance, and optimized space utilization, significantly enhancing inventory management and operational decision-making.

Virtualized Fulfillment

Conventional warehousing relies on physical storage facilities with fixed inventory locations, limiting flexibility and scalability in fulfillment operations. Cloud warehousing leverages virtualized fulfillment technology to dynamically allocate inventory across multiple channels, enhancing real-time inventory visibility and accelerating order processing efficiency.

Edge Logistics

Conventional warehousing relies on centralized storage facilities, often causing delays in order fulfillment and limited real-time inventory visibility, whereas cloud warehousing leverages edge logistics by integrating IoT and AI at distributed locations to optimize inventory management and accelerate last-mile delivery. Edge logistics enhances cloud warehousing efficiency by processing data locally at warehouse sites, reducing latency and enabling faster decision-making for dynamic demand and supply chain disruptions.

Inventory as a Service (IaaS)

Conventional warehousing relies on physical storage facilities with fixed capacity and manual inventory management, limiting scalability and real-time tracking. Cloud warehousing offers Inventory as a Service (IaaS), enabling dynamic inventory allocation, real-time data integration, and cost-effective scalability through virtual storage solutions.

API-Driven Warehouse Management

Conventional warehousing relies on manual inventory tracking and limited automation, leading to inefficiencies in real-time data access and integration. Cloud warehousing leverages API-driven warehouse management systems to enable seamless data exchange, real-time inventory updates, and scalable automation that optimize operational agility and reduce downtime.

Wearhouse (Wearable-enabled Warehouse)

Wearable-enabled warehouses leverage cloud warehousing technology to provide real-time inventory tracking, hands-free operations, and enhanced worker productivity compared to conventional warehousing, which relies on manual data entry and static databases. Cloud warehousing integrates wearable devices for seamless data synchronization, reducing errors and operational downtime while improving scalability and flexibility in supply chain management.

Multi-Tenant Storage

Conventional warehousing relies on physical storage facilities dedicated to individual businesses, limiting scalability and flexibility in inventory management. Cloud warehousing utilizes multi-tenant storage architecture, enabling multiple clients to share storage resources dynamically, optimizing space utilization and reducing operational costs through virtualized data environments.

On-Demand Storage Scalability

Conventional warehousing relies on fixed physical space, limiting scalability and often leading to costly overprovisioning or space shortages during peak demand. Cloud warehousing offers on-demand storage scalability through flexible virtual resources, allowing businesses to dynamically adjust capacity and optimize costs in real-time.

Real-Time Inventory Visibility

Conventional warehousing often faces challenges with delayed inventory updates due to manual tracking systems, limiting real-time visibility. Cloud warehousing leverages IoT sensors and integrated software platforms to provide accurate, up-to-the-minute inventory data accessible from any location.

Omnichannel Cloud Integration

Cloud warehousing enables seamless omnichannel integration by centralizing data and providing real-time inventory visibility across multiple sales channels, enhancing order accuracy and fulfillment speed. Conventional warehousing often lacks this scalability and flexibility, resulting in slower response times and increased errors in omnichannel order management.

Conventional Warehousing vs Cloud Warehousing Infographic

industrydif.com

industrydif.com