Manual sorting in warehousing relies on human labor for identifying and categorizing products, resulting in slower processing times and higher error rates. Vision picking uses advanced imaging technologies and AI algorithms to accurately recognize and select items, significantly improving speed and accuracy. Integrating vision picking enhances operational efficiency and reduces labor costs compared to traditional manual sorting methods.

Table of Comparison

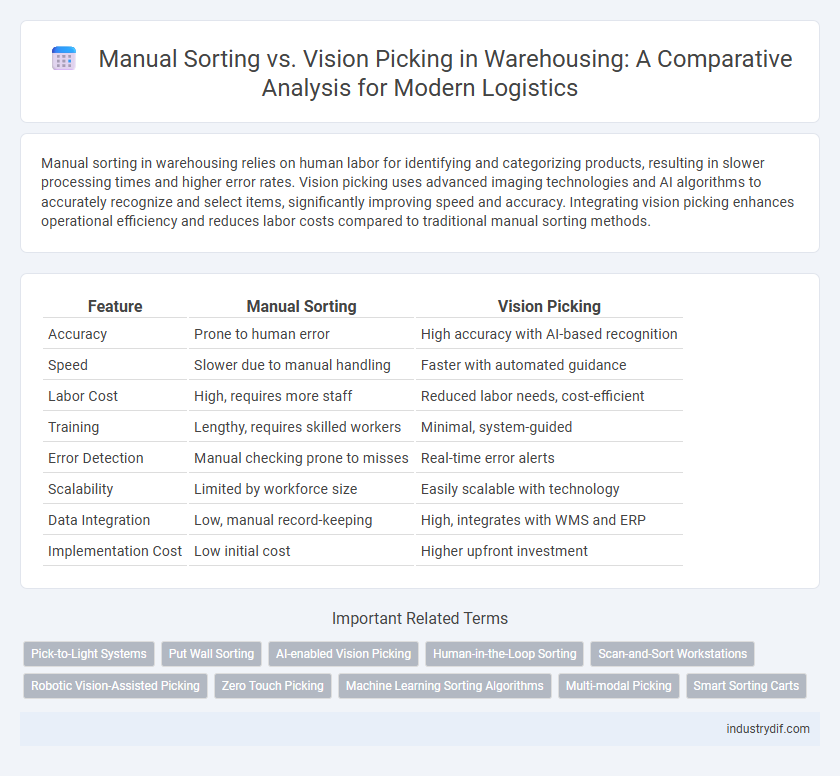

| Feature | Manual Sorting | Vision Picking |

|---|---|---|

| Accuracy | Prone to human error | High accuracy with AI-based recognition |

| Speed | Slower due to manual handling | Faster with automated guidance |

| Labor Cost | High, requires more staff | Reduced labor needs, cost-efficient |

| Training | Lengthy, requires skilled workers | Minimal, system-guided |

| Error Detection | Manual checking prone to misses | Real-time error alerts |

| Scalability | Limited by workforce size | Easily scalable with technology |

| Data Integration | Low, manual record-keeping | High, integrates with WMS and ERP |

| Implementation Cost | Low initial cost | Higher upfront investment |

Introduction to Manual Sorting and Vision Picking in Warehousing

Manual sorting in warehousing involves workers physically handling and categorizing items based on labels, shapes, or sizes, which can be time-consuming and prone to human error. Vision picking utilizes advanced computer vision technology and augmented reality glasses to guide operators through order selection, increasing accuracy and efficiency by recognizing objects and providing real-time instructions. Incorporating vision picking systems improves throughput and reduces labor costs compared to traditional manual sorting methods.

Defining Manual Sorting: Processes and Applications

Manual sorting in warehousing involves human workers physically organizing products based on attributes such as size, shape, or destination, ensuring accuracy in complex or variable inventory. This process is critical in environments where product variability and handling nuances exceed current automation capabilities. Common applications include order fulfillment in e-commerce, quality control, and sorting irregular or fragile items that require careful handling.

Vision Picking Technology: How It Works

Vision picking technology uses advanced cameras and image recognition software to identify and locate items within a warehouse accurately. Workers wear smart glasses or handheld devices that display real-time visual instructions, improving picking accuracy and efficiency. This technology reduces human errors and accelerates order fulfillment compared to traditional manual sorting methods.

Key Differences Between Manual Sorting and Vision Picking

Manual sorting relies on human labor to identify, categorize, and organize products, often leading to slower processing times and higher error rates. Vision picking integrates advanced imaging technology and augmented reality, enabling workers to quickly locate and accurately pick items with real-time digital guidance. The key differences include increased efficiency, reduced errors, and enhanced scalability offered by vision picking compared to traditional manual sorting methods.

Efficiency and Accuracy: A Comparative Analysis

Manual sorting in warehousing often results in slower processing times and higher error rates due to human fatigue and variability, impacting overall operational efficiency. Vision picking systems leverage advanced image recognition and real-time data processing to enhance picking accuracy and speed, reducing errors and increasing throughput. Implementing vision picking can lead to measurable improvements in warehouse productivity and order fulfillment precision compared to traditional manual sorting methods.

Labor Requirements and Workforce Impacts

Manual sorting in warehousing demands significant labor input, often requiring extensive workforce training and physical stamina to handle high volumes of items efficiently. Vision picking technology reduces the need for manual labor by automating item identification and location, which decreases worker fatigue and minimizes human errors. Implementing vision picking can lead to optimized workforce allocation, improved productivity, and lower operational costs through reduced dependency on manual labor.

Cost Implications: Manual vs Vision-Based Systems

Manual sorting in warehousing typically incurs higher labor costs due to the need for extensive human workforce and training, while vision-based picking systems require significant initial capital investment but reduce long-term operational expenses through automation and increased accuracy. Vision picking technologies lower error rates, thereby minimizing costly mistakes and returns, whereas manual sorting can lead to inefficiencies and higher error-related costs. Over time, vision-based systems offer a more cost-effective solution by enhancing productivity and reducing labor dependency despite higher upfront expenditures.

Scalability and Adaptability in Warehouse Operations

Manual sorting in warehouse operations offers limited scalability and adaptability due to reliance on human labor, which can be inconsistent and slower during peak periods. Vision picking systems utilize advanced image recognition and AI technology, enabling rapid scaling and seamless adaptation to varying inventory types and order complexities. Integrating vision picking enhances operational efficiency, reduces errors, and supports dynamic workflows essential for evolving warehouse demands.

Common Challenges and Solutions

Manual sorting in warehousing often faces challenges such as human error, slower processing speeds, and worker fatigue, which lead to decreased efficiency and increased operational costs. Vision picking technology addresses these issues by using augmented reality and barcode scanning to guide workers accurately, reducing mistakes and improving throughput. Implementing vision picking can enhance inventory accuracy and streamline workflows, offering a scalable solution for handling complex sorting tasks.

Future Trends in Automated Warehouse Picking

Future trends in automated warehouse picking emphasize increased integration of vision picking systems powered by AI and machine learning, allowing for faster and more accurate item identification compared to manual sorting. Advancements in robotics and computer vision technologies enable warehouses to reduce human error and boost operational efficiency, driving a shift toward fully automated picking solutions. Predictive analytics and real-time data processing further enhance decision-making, optimizing inventory management and throughput in modern warehouses.

Related Important Terms

Pick-to-Light Systems

Pick-to-light systems significantly enhance manual sorting by reducing errors and increasing picking speed through real-time visual guidance, outperforming traditional vision picking methods that rely heavily on operator interpretation. These systems optimize warehouse efficiency by streamlining the pick process with illuminated indicators, minimizing cognitive load and improving accuracy in high-volume order fulfillment environments.

Put Wall Sorting

Put wall sorting accelerates order fulfillment by combining manual sorting precision with strategic product placement, reducing picker travel time and error rates. Vision picking enhances this process by guiding workers through augmented reality, increasing sorting accuracy and operational efficiency in complex warehouse environments.

AI-enabled Vision Picking

AI-enabled vision picking significantly enhances warehousing efficiency by using advanced machine learning algorithms and computer vision to accurately identify and sort items, reducing human error and boosting order accuracy. Compared to manual sorting, this technology accelerates the picking process by automating item recognition and verification, leading to improved productivity and lower operational costs.

Human-in-the-Loop Sorting

Human-in-the-loop sorting integrates manual sorting with vision picking technology to enhance accuracy and flexibility in complex warehousing environments. This hybrid approach leverages human judgment for anomaly detection while vision systems optimize speed and reduce error rates, ultimately increasing overall operational efficiency.

Scan-and-Sort Workstations

Scan-and-sort workstations enhance warehouse efficiency by integrating manual sorting with vision picking technology, allowing operators to accurately identify and sort items through barcode scanning or image recognition. This hybrid approach reduces errors and accelerates processing times compared to purely manual methods, improving overall inventory accuracy and throughput.

Robotic Vision-Assisted Picking

Robotic vision-assisted picking leverages advanced image recognition and machine learning algorithms to enhance accuracy and speed in warehouse sorting compared to manual methods. This technology reduces human error, increases throughput, and enables real-time inventory tracking for improved operational efficiency.

Zero Touch Picking

Zero Touch Picking significantly enhances warehouse efficiency by eliminating manual sorting errors through advanced vision picking technology that uses cameras and AI to identify and select items quickly. This automated system reduces labor costs, accelerates order fulfillment, and improves accuracy compared to traditional manual sorting methods.

Machine Learning Sorting Algorithms

Machine learning sorting algorithms enhance warehousing efficiency by automating item classification and reducing errors compared to manual sorting methods. Vision picking systems leverage these algorithms to rapidly analyze visual data, enabling precise and scalable sorting processes that increase throughput and accuracy.

Multi-modal Picking

Multi-modal picking integrates manual sorting and vision picking technologies to enhance accuracy and efficiency in warehouse operations, combining human intuition with advanced visual guidance. This hybrid approach reduces picking errors, accelerates order fulfillment, and optimizes inventory management by leveraging real-time data and automated assistance.

Smart Sorting Carts

Smart sorting carts equipped with integrated vision picking technology significantly enhance accuracy and speed in warehousing operations by automating item identification and reducing human errors compared to manual sorting. These carts leverage advanced sensors and AI algorithms to streamline the sorting process, increase throughput, and optimize labor efficiency in distribution centers.

Manual Sorting vs Vision Picking Infographic

industrydif.com

industrydif.com