Compostable products break down fully in commercial composting facilities where conditions like temperature and humidity are carefully controlled, ensuring they decompose into nutrient-rich soil. Home-compostable items are specifically designed to break down in typical backyard compost setups, which have lower temperatures and less controlled environments. Understanding the difference is essential for effective waste management, as using commercial compostable items in home compost bins can lead to incomplete decomposition and contamination.

Table of Comparison

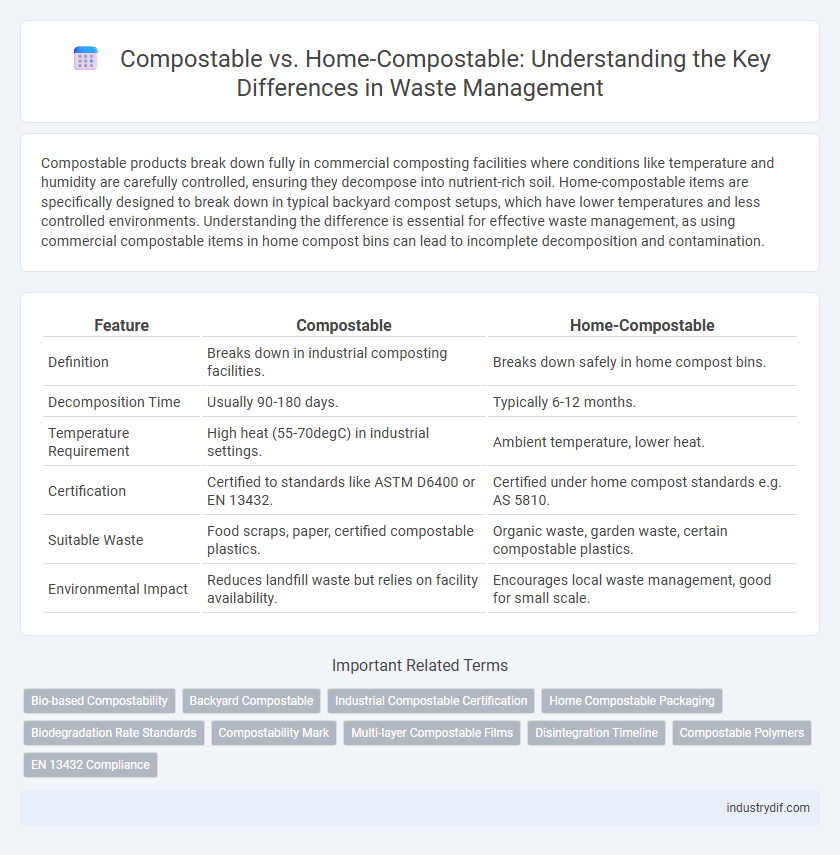

| Feature | Compostable | Home-Compostable |

|---|---|---|

| Definition | Breaks down in industrial composting facilities. | Breaks down safely in home compost bins. |

| Decomposition Time | Usually 90-180 days. | Typically 6-12 months. |

| Temperature Requirement | High heat (55-70degC) in industrial settings. | Ambient temperature, lower heat. |

| Certification | Certified to standards like ASTM D6400 or EN 13432. | Certified under home compost standards e.g. AS 5810. |

| Suitable Waste | Food scraps, paper, certified compostable plastics. | Organic waste, garden waste, certain compostable plastics. |

| Environmental Impact | Reduces landfill waste but relies on facility availability. | Encourages local waste management, good for small scale. |

Understanding Compostable vs Home-Compostable

Compostable materials break down into non-toxic components within commercial composting facilities that maintain high temperatures and controlled conditions, ensuring efficient decomposition. Home-compostable items are specifically designed to biodegrade in typical backyard compost setups, which operate at lower temperatures and less controlled environments. Understanding the distinction helps consumers properly sort waste, preventing contamination in commercial compost systems and promoting effective composting at home.

Key Industry Standards and Certifications

Compostable products meet industrial composting standards such as ASTM D6400 and EN 13432, ensuring they break down efficiently in regulated commercial facilities. Home-compostable items comply with certifications like AS 5810, demonstrating their ability to decompose safely in backyard compost systems without specialized conditions. Understanding these key certifications helps businesses and consumers choose appropriate products aligned with specific waste management environments.

Material Composition Differences

Compostable products typically consist of industrial-grade materials such as PLA (polylactic acid), PHA (polyhydroxyalkanoates), and cellulose blends designed to break down efficiently in high-temperature commercial composting facilities. Home-compostable items are made from natural fibers like cotton, paper, or plant-based biopolymers that decompose slower under ambient outdoor conditions without requiring specialized environments. Understanding these material composition differences is critical for proper disposal and ensuring effective biodegradation in the intended composting system.

Breakdown Processes Explained

Compostable materials break down through microbial activity in industrial composting facilities, which provide optimal temperature, moisture, and aeration conditions to accelerate decomposition. Home-compostable items are designed to degrade efficiently in backyard compost bins, where temperatures and conditions are less controlled, requiring longer timeframes but still resulting in nutrient-rich soil. Understanding the specific breakdown processes helps consumers choose products suitable for their local composting environment, reducing waste and supporting sustainable disposal practices.

Optimal Conditions for Degradation

Compostable materials require controlled industrial composting facilities with high temperatures between 130degF and 160degF, consistent moisture, and adequate oxygen levels to fully break down within 90 to 180 days. Home-compostable items degrade optimally at lower temperatures around 70degF to 90degF and need a balanced mix of green and brown organic waste, regular aeration, and sufficient moisture to decompose efficiently. Failure to meet these specific temperature, moisture, and oxygen conditions can significantly slow the degradation process of both compostable and home-compostable materials.

Industrial Composting Facilities vs Home Composting

Industrial composting facilities process compostable materials at higher temperatures and controlled conditions, breaking down items like bioplastics and food packaging more efficiently than home composting can achieve. Home composting suits organic kitchen scraps and yard waste but often cannot decompose materials labeled as industrially compostable, leading to contamination in backyard systems. Understanding the distinction supports proper waste sorting, reducing landfill inputs and optimizing compost quality in both municipal and residential programs.

Environmental Impact and Benefits

Compostable materials break down in industrial composting facilities under higher temperatures, ensuring faster decomposition and reduced landfill waste, while home-compostable items decompose in backyard compost piles but may take longer and require specific conditions. Both reduce methane emissions compared to traditional plastics, yet industrial composting's controlled environment offers more reliable nutrient-rich soil output, accelerating environmental benefits. Choosing the appropriate compostable option supports waste diversion from landfills, enhances soil health, and lowers greenhouse gas emissions, crucial for sustainable waste management.

Common Products and Packaging Uses

Compostable products, such as certified food containers, utensils, and coffee cups, are designed to break down in industrial composting facilities that reach higher temperatures. Home-compostable items, including tea bags, fruit and vegetable scraps, and certain paper products, degrade effectively in backyard compost bins under lower temperature conditions. Packaging uses increasingly favor home-compostable materials for consumer convenience, while commercial composting remains essential for handling complex packaging with additives or coatings.

Labeling, Misconceptions, and Consumer Awareness

Compostable labels indicate that a product can break down in industrial composting facilities, whereas home-compostable items are designed to decompose in backyard compost setups under variable conditions. Mislabeling and lack of standardized definitions lead to consumer confusion, often resulting in improper disposal and contamination of compost streams. Educating consumers on certification logos like ASTM D6400 and EN 13432 improves awareness and supports effective waste sorting to enhance organic recycling efforts.

Regulatory Challenges and Global Trends

Regulatory challenges in compostable versus home-compostable waste materials center on inconsistent standards and certification processes across regions, complicating global compliance and market adoption. Home-compostable products must meet stricter biodegradability criteria to break down effectively in domestic composting environments, whereas industrial compostable items rely on controlled conditions found in municipal facilities. Global trends indicate increasing regulatory alignment efforts, with the European Union's EN 13432 and the ASTM D6400 standards influencing policies to promote clear labeling and circular economy principles in waste management.

Related Important Terms

Bio-based Compostability

Bio-based compostability refers to materials derived from renewable biological sources that can break down into non-toxic components in composting environments, supporting nutrient-rich soil formation. Home-compostable items are specifically designed to decompose effectively in less controlled, lower-temperature settings typical of household compost bins, ensuring practical biodegradation outside industrial facilities.

Backyard Compostable

Backyard compostable materials break down efficiently in home composting systems without industrial intervention, supporting sustainable waste management by returning nutrients to soil. These items, unlike general compostable products, are designed to decompose within typical backyard conditions, reducing landfill use and promoting organic recycling.

Industrial Compostable Certification

Industrial compostable certification ensures that compostable materials break down efficiently in high-temperature, controlled environments typical of industrial facilities, unlike home-compostable products designed for lower temperature, less regulated settings. Certifications like ASTM D6400 and EN 13432 guarantee that industrial compostable items meet specific biodegradability and disintegration standards within a set timeframe, promoting effective waste management and reducing landfill impact.

Home Compostable Packaging

Home compostable packaging is specifically designed to break down in domestic composting systems within 90 to 180 days, meeting standards such as ASTM D6400 or EN 13432 for home compostability. Unlike industrial compostable materials that require high temperatures and controlled conditions, home compostable packaging decomposes efficiently in garden compost bins, reducing waste and supporting sustainable circular economy practices.

Biodegradation Rate Standards

Compostable materials meet industrial standards such as ASTM D6400, requiring biodegradation within 180 days at controlled temperatures, while home-compostable items adhere to more lenient criteria like AS 5810, enabling breakdown in varied environmental conditions typically within 12 months. The biodegradation rate standards distinguish these categories by specifying timeframes, temperature ranges, and microbial activity levels necessary for effective decomposition.

Compostability Mark

The Compostability Mark certifies that products meet specific standards for industrial composting facilities, ensuring they break down safely without leaving harmful residues. Home-compostable items, unlike those certified only for industrial composting, decompose effectively in residential compost bins under typical outdoor conditions.

Multi-layer Compostable Films

Multi-layer compostable films designed for home composting degrade effectively under typical backyard compost conditions, unlike some industrial compostable films that require higher temperatures and controlled environments. These films balance durability with environmental benefits, breaking down without leaving toxic residues, thus supporting sustainable waste management practices.

Disintegration Timeline

Compostable materials typically disintegrate within 90 to 180 days under industrial composting conditions, while home-compostable items break down more slowly, often requiring up to 12 months due to lower temperatures and less controlled environments. Understanding these disintegration timelines is essential for effective waste management and proper composting system selection.

Compostable Polymers

Compostable polymers are designed to break down in industrial composting facilities where controlled temperature, humidity, and microbial activity accelerate degradation, unlike home-compostable polymers which decompose in less controlled, domestic environments. These polymers, often derived from renewable resources such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA), provide sustainable alternatives to conventional plastics by converting waste into nutrient-rich compost and reducing landfill accumulation.

EN 13432 Compliance

Compostable products certified under EN 13432 must disintegrate by at least 90% within 12 weeks and biodegrade by 90% within six months in industrial composting conditions, while home-compostable items require similar biodegradability but at lower temperatures found in domestic compost systems. EN 13432 compliance ensures waste materials break down efficiently without leaving toxic residues, distinguishing industrial compostables from home-compostable products that degrade more slowly under natural environmental conditions.

Compostable vs Home-Compstable Infographic

industrydif.com

industrydif.com