Composting and in-vessel aerobic digestion both break down organic waste into nutrient-rich material but differ in process control and speed. Composting relies on natural aerobic decomposition exposed to air, making it slower and more variable, while in-vessel aerobic digestion occurs inside a controlled environment, accelerating decomposition and minimizing odor. The choice between these methods impacts efficiency, space requirements, and environmental emissions in organic waste management.

Table of Comparison

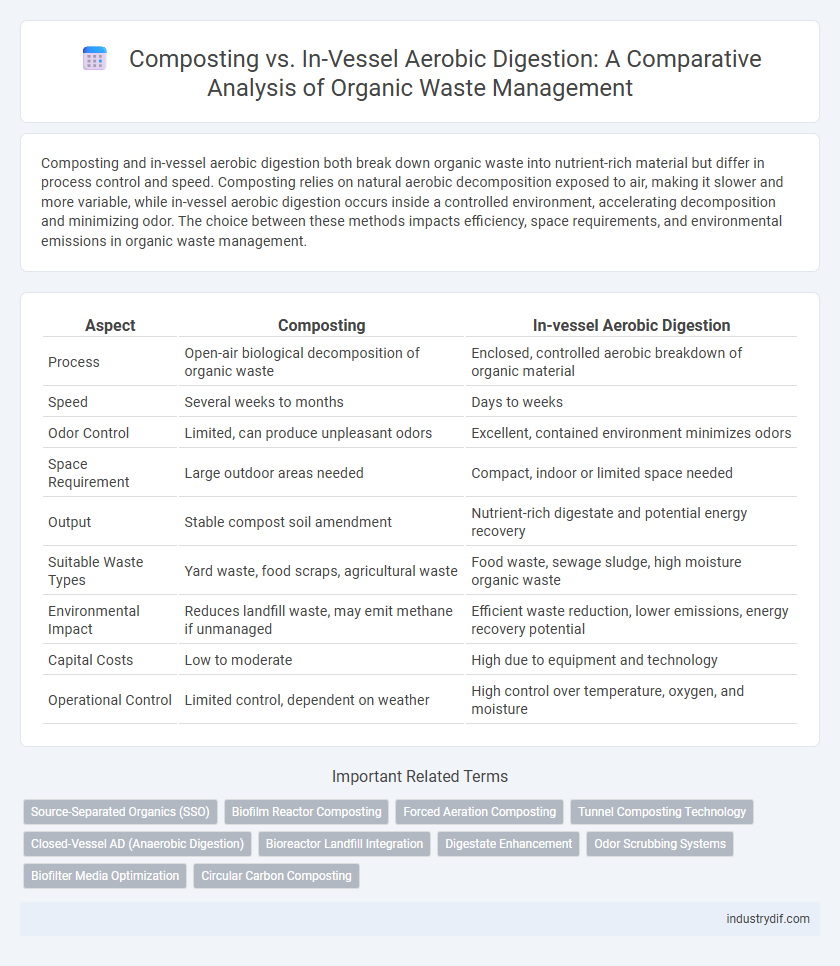

| Aspect | Composting | In-vessel Aerobic Digestion |

|---|---|---|

| Process | Open-air biological decomposition of organic waste | Enclosed, controlled aerobic breakdown of organic material |

| Speed | Several weeks to months | Days to weeks |

| Odor Control | Limited, can produce unpleasant odors | Excellent, contained environment minimizes odors |

| Space Requirement | Large outdoor areas needed | Compact, indoor or limited space needed |

| Output | Stable compost soil amendment | Nutrient-rich digestate and potential energy recovery |

| Suitable Waste Types | Yard waste, food scraps, agricultural waste | Food waste, sewage sludge, high moisture organic waste |

| Environmental Impact | Reduces landfill waste, may emit methane if unmanaged | Efficient waste reduction, lower emissions, energy recovery potential |

| Capital Costs | Low to moderate | High due to equipment and technology |

| Operational Control | Limited control, dependent on weather | High control over temperature, oxygen, and moisture |

Introduction to Organic Waste Management

Organic waste management involves methods like composting and in-vessel aerobic digestion, which both biologically decompose organic materials into valuable end-products. Composting relies on natural aerobic microbial activity in open piles or windrows, producing nutrient-rich compost for soil enhancement. In-vessel aerobic digestion uses controlled enclosed environments to accelerate decomposition, reducing odors and processing time while maintaining aerobic conditions for optimal organic matter stabilization.

Defining Composting and In-vessel Aerobic Digestion

Composting is a natural process of organic waste decomposition facilitated by microorganisms under controlled aerobic conditions, resulting in nutrient-rich humus suitable for soil amendment. In-vessel aerobic digestion is a contained method of aerobic decomposition where organic waste is processed within a sealed environment, enabling precise control of temperature, oxygen, and moisture levels to accelerate stabilization. Both techniques reduce organic waste volume and produce valuable end products, but in-vessel systems offer faster processing and minimize environmental impact through controlled emissions.

Key Processes: Traditional vs In-Vessel Methods

Composting involves the natural aerobic decomposition of organic waste in open piles or windrows, relying on microbial activity regulated by temperature, moisture, and oxygen levels to break down materials gradually. In-vessel aerobic digestion occurs within a controlled, enclosed environment, enhancing process efficiency through precise regulation of environmental factors like airflow, temperature, and moisture, which accelerates organic matter breakdown. Traditional composting typically requires longer processing times and significant space, whereas in-vessel digestion offers faster stabilization and minimizes odors, making it suitable for urban waste management.

Input Material Suitability and Preparation

Composting efficiently processes a wide range of organic waste such as garden clippings, food scraps, and paper, requiring minimal preprocessing aside from shredding or chopping to enhance aeration. In-vessel aerobic digestion demands more homogeneous inputs like food waste, manure, and biosolids, often pre-treated through sorting and grinding to optimize microbial activity. Both methods necessitate moisture and carbon-to-nitrogen ratio adjustments but vary significantly in input flexibility and preparation intensity.

Efficiency and Processing Time Comparison

Composting typically requires 2 to 6 months to break down organic waste, relying on natural microbial activity and aerobic conditions, whereas in-vessel aerobic digestion accelerates the process to 10 to 20 days by controlling temperature, oxygen, and moisture in a closed environment. In-vessel systems enhance pathogen reduction and odor control, delivering higher efficiency and consistent quality of the end product compared to traditional composting. This method's controlled environment allows for optimized degradation rates, making it a superior choice for large-scale or rapid organic waste processing.

Space Requirements and Scalability

Composting typically requires significantly larger outdoor space, ranging from 500 to 5,000 square feet per system, making it less feasible for urban areas with limited land availability. In-vessel aerobic digestion systems are compact, often requiring only 100 to 1,000 square feet, enabling scalability in dense environments and allowing for modular expansion to accommodate increased waste volumes. These systems offer controlled processing conditions, resulting in faster waste turnover and more predictable outputs compared to traditional composting methods.

Environmental Impact and Emissions

Composting generates lower greenhouse gas emissions compared to in-vessel aerobic digestion by naturally breaking down organic waste with minimal energy input, reducing methane release. In-vessel aerobic digestion offers controlled conditions that accelerate decomposition and reduce odors but requires more energy, potentially increasing carbon emissions. Both methods help divert organic waste from landfills, significantly lowering overall environmental impact by mitigating methane emissions from anaerobic decay.

End Product Quality and Applications

Composting produces nutrient-rich humus ideal for soil amendment in agriculture and landscaping, while in-vessel aerobic digestion generates stabilized organic matter with consistent moisture and pathogen levels suitable for controlled environments like greenhouses. The end product from in-vessel digestion typically exhibits higher pathogen reduction and odor control, enhancing its safety and usability in sensitive applications. Both methods contribute to organic waste diversion, but in-vessel systems offer superior process control and product uniformity for commercial horticulture and landscaping uses.

Cost Considerations and Operational Complexity

Composting generally requires lower initial investment and operational costs compared to in-vessel aerobic digestion, making it suitable for small to medium-scale waste management. In-vessel aerobic digestion involves higher capital expenditure due to enclosed system infrastructure and advanced technology but offers faster processing times and better odor control. Operational complexity is greater in in-vessel systems, requiring skilled personnel and continuous monitoring, whereas composting can be managed with simpler equipment and less technical expertise.

Industry Trends and Future Outlook

Composting remains a widely adopted organic waste treatment method, favored for its simplicity and low operational costs, with industry trends showing increased integration of automated monitoring systems to optimize decomposition rates. In-vessel aerobic digestion is gaining momentum due to its controlled environment, faster processing times, and ability to handle diverse organic waste streams, making it a preferred choice for urban and industrial-scale applications. Future outlooks highlight continued innovation in in-vessel technology, including energy recovery enhancements and scalability improvements to meet stricter environmental regulations and growing demand for circular economy solutions.

Related Important Terms

Source-Separated Organics (SSO)

Composting of Source-Separated Organics (SSO) involves aerobic decomposition in open or covered piles, effectively reducing waste volume and producing nutrient-rich soil amendments, while being cost-efficient for small to medium-scale operations. In-vessel aerobic digestion offers enhanced control over temperature, moisture, and aeration for SSO, leading to faster stabilization and pathogen reduction, making it ideal for urban areas with strict environmental regulations.

Biofilm Reactor Composting

Biofilm reactor composting enhances organic waste decomposition by using microbial biofilms to accelerate aerobic digestion, resulting in higher efficiency and faster stabilization compared to traditional composting methods. This process optimizes oxygen transfer and nutrient cycling, reducing greenhouse gas emissions and producing nutrient-rich compost suitable for sustainable agriculture.

Forced Aeration Composting

Forced aeration composting accelerates organic waste decomposition by actively supplying oxygen through a mechanical aeration system, optimizing microbial activity and reducing processing time compared to passive composting. This method enhances temperature control and odor management, making it more efficient for handling large-scale organic waste than in-vessel aerobic digestion, which confines the process to sealed containers.

Tunnel Composting Technology

Tunnel composting technology accelerates organic waste decomposition by maintaining controlled aerobic conditions within enclosed tunnels, optimizing temperature, moisture, and airflow for efficient microbial activity. Unlike in-vessel aerobic digestion, tunnel composting offers a scalable solution with reduced odor emissions and easy automation, making it ideal for large-scale organic waste management.

Closed-Vessel AD (Anaerobic Digestion)

Closed-vessel anaerobic digestion (AD) offers a controlled environment for organic waste breakdown, producing biogas and nutrient-rich digestate with minimal odor and emission risks compared to composting. This technology enhances waste-to-energy conversion efficiency while reducing greenhouse gas emissions, making it a sustainable alternative for managing organic waste streams.

Bioreactor Landfill Integration

Composting and in-vessel aerobic digestion both enhance organic waste decomposition but differ in control and efficiency; integrating bioreactor landfills with these methods accelerates leachate recirculation, boosting microbial activity and methane recovery. Bioreactor landfill integration optimizes waste stabilization by combining aerobic digestion's controlled environment with landfill's large-scale waste containment, reducing greenhouse gas emissions and improving resource recovery.

Digestate Enhancement

Composting produces nutrient-rich, stable digestate that improves soil structure and fertility by enhancing organic matter content and microbial activity. In-vessel aerobic digestion accelerates the breakdown process, yielding digestate with higher pathogen reduction and consistency, ideal for large-scale agriculture and controlled waste management systems.

Odor Scrubbing Systems

Composting odor scrubbing systems rely on biofilters and activated carbon to mitigate ammonia and volatile organic compounds, ensuring minimal environmental impact. In-vessel aerobic digestion employs closed-system scrubbers integrated with chemical or biological treatment to control odors more effectively in confined spaces.

Biofilter Media Optimization

Biofilter media optimization enhances contaminant removal efficiency in both composting and in-vessel aerobic digestion by improving microbial activity and airflow distribution. Selecting media with high porosity and moisture retention capacity directly influences odor control and organic waste stabilization during biofiltration processes.

Circular Carbon Composting

Circular Carbon Composting transforms organic waste into nutrient-rich compost through controlled aerobic decomposition, promoting soil health and reducing landfill methane emissions. In contrast, in-vessel aerobic digestion accelerates organic matter breakdown within a sealed environment, optimizing carbon recycling and minimizing odors, making it a scalable solution for urban waste management.

Composting vs In-vessel Aerobic Digestion Infographic

industrydif.com

industrydif.com