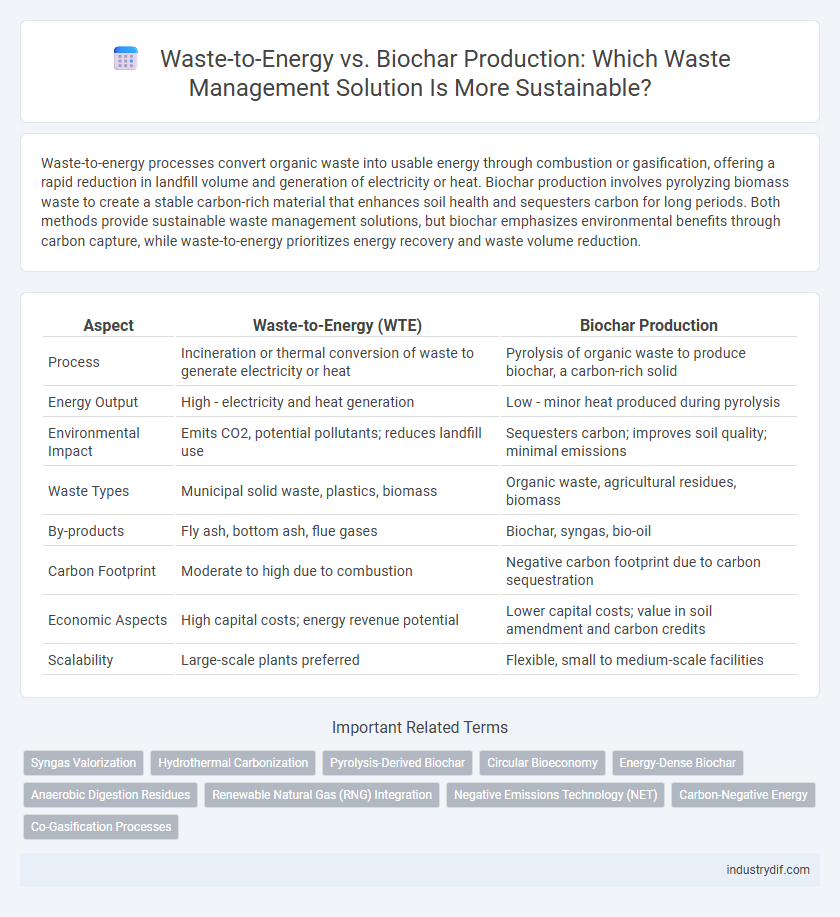

Waste-to-energy processes convert organic waste into usable energy through combustion or gasification, offering a rapid reduction in landfill volume and generation of electricity or heat. Biochar production involves pyrolyzing biomass waste to create a stable carbon-rich material that enhances soil health and sequesters carbon for long periods. Both methods provide sustainable waste management solutions, but biochar emphasizes environmental benefits through carbon capture, while waste-to-energy prioritizes energy recovery and waste volume reduction.

Table of Comparison

| Aspect | Waste-to-Energy (WTE) | Biochar Production |

|---|---|---|

| Process | Incineration or thermal conversion of waste to generate electricity or heat | Pyrolysis of organic waste to produce biochar, a carbon-rich solid |

| Energy Output | High - electricity and heat generation | Low - minor heat produced during pyrolysis |

| Environmental Impact | Emits CO2, potential pollutants; reduces landfill use | Sequesters carbon; improves soil quality; minimal emissions |

| Waste Types | Municipal solid waste, plastics, biomass | Organic waste, agricultural residues, biomass |

| By-products | Fly ash, bottom ash, flue gases | Biochar, syngas, bio-oil |

| Carbon Footprint | Moderate to high due to combustion | Negative carbon footprint due to carbon sequestration |

| Economic Aspects | High capital costs; energy revenue potential | Lower capital costs; value in soil amendment and carbon credits |

| Scalability | Large-scale plants preferred | Flexible, small to medium-scale facilities |

Overview of Waste-to-Energy and Biochar Production

Waste-to-Energy (WtE) facilities convert municipal solid waste into electricity or heat through combustion, reducing landfill volume and generating renewable energy from non-recyclable waste. Biochar production involves pyrolyzing organic waste materials to create a stable form of carbon that enhances soil fertility and sequesters carbon dioxide. Both technologies offer sustainable waste management solutions, with WtE prioritizing energy recovery and biochar focusing on carbon capture and soil improvement.

Comparing Waste Conversion Technologies

Waste-to-energy (WTE) technologies primarily convert municipal solid waste into electricity or heat through combustion, offering rapid volume reduction and energy recovery efficiencies of 20-30%. Biochar production utilizes pyrolysis to thermally decompose organic waste in low-oxygen environments, yielding a stable carbon-rich product that enhances soil health and sequesters carbon for hundreds of years. While WTE delivers immediate power generation with higher greenhouse gas emissions, biochar emphasizes long-term carbon storage and soil benefits, representing complementary approaches in sustainable waste management.

Feedstock Requirements and Material Suitability

Waste-to-energy processes prioritize feedstocks with high calorific value, such as mixed municipal solid waste and industrial refuse, to maximize energy output through combustion or gasification. Biochar production requires biomass-rich inputs like agricultural residues, forestry waste, or organic-rich sludge, which favor pyrolysis to produce stable carbon structures and enhance soil quality. Material suitability hinges on moisture content and contamination levels, with waste-to-energy tolerating higher moisture and mixed content, while biochar yields improve with clean, low-moisture, lignocellulosic feedstocks.

Energy Output: Efficiency and Applications

Waste-to-energy (WTE) technologies convert municipal solid waste into electricity with an average efficiency of 20-27%, suitable for consistent power generation in urban grids. Biochar production via pyrolysis achieves lower immediate energy output but generates stable carbon-rich material beneficial for soil enhancement and carbon sequestration. While WTE maximizes electricity output, biochar's energy efficiency lies in its dual role of waste reduction and long-term environmental benefits through soil application.

Environmental Impact and Emission Profiles

Waste-to-Energy (WTE) plants incinerate municipal solid waste, generating electricity but emitting significant amounts of CO2, NOx, and dioxins, contributing to air pollution and greenhouse gas emissions. Biochar production involves pyrolyzing organic waste under limited oxygen, resulting in carbon-rich char that sequesters carbon in soil while reducing methane emissions from decomposition. Compared to WTE, biochar has a lower emission profile and offers long-term environmental benefits through soil enhancement and carbon storage.

Byproducts: Electricity, Heat, and Biochar

Waste-to-energy processes generate electricity and heat by combusting waste materials, offering immediate energy recovery but producing emissions that require control technologies. Biochar production, through pyrolysis, converts organic waste into stable carbon-rich biochar while simultaneously generating syngas and bio-oil that can be used for heat and power. Byproducts from biochar production enhance soil quality and carbon sequestration, providing long-term environmental benefits beyond the immediate energy outputs of waste-to-energy plants.

Regulatory and Policy Considerations

Waste-to-Energy (WTE) facilities face stringent emissions standards and regulatory hurdles under policies like the Clean Air Act, requiring advanced pollution control technologies to meet particulate and dioxin limits. Biochar production benefits from supportive agricultural and carbon sequestration policies, often qualifying for carbon credits and sustainability incentives under frameworks such as the U.S. Renewable Fuel Standard and the European Green Deal. Regulatory environments prioritize lifecycle greenhouse gas emissions, influencing investment and permitting processes in both waste-to-energy and biochar sectors.

Economic Feasibility and Market Trends

Waste-to-energy (WTE) plants benefit from established infrastructure and government incentives, making them economically viable with predictable revenue streams from energy sales and tipping fees. Biochar production, while emerging, shows promising market growth due to increasing demand for sustainable agriculture solutions and carbon sequestration credits, though high initial costs and technology scalability remain challenges. Market trends indicate rising investment in biochar driven by environmental regulations and consumer preference for eco-friendly products, contrasting with the steady but slower growth observed in conventional WTE technologies.

Carbon Sequestration and Climate Benefits

Waste-to-Energy (WTE) processes convert waste into electricity or heat, releasing significant CO2 emissions, which limits their long-term carbon sequestration potential. Biochar production stabilizes carbon by converting biomass waste into a porous, carbon-rich material that sequesters carbon in soils for hundreds to thousands of years, enhancing soil health and reducing atmospheric CO2. Compared to WTE, biochar offers superior climate benefits by effectively locking carbon in stable forms and reducing methane emissions from organic waste decomposition.

Future Prospects for Waste Valorization

Waste-to-energy technologies convert organic waste into electricity and heat, offering immediate reductions in landfill use and greenhouse gas emissions. Biochar production enhances soil fertility while sequestering carbon, presenting a sustainable approach to long-term waste valorization. Future prospects emphasize integrating both methods to optimize energy recovery and environmental benefits, addressing circular economy goals and climate change mitigation.

Related Important Terms

Syngas Valorization

Waste-to-energy processes convert organic waste into electricity and heat primarily through combustion, producing syngas rich in CO and H2 that can be valorized for power generation or chemical synthesis. In contrast, biochar production from pyrolysis generates syngas as a byproduct, which contains valuable H2 and CO components suitable for upgrading into fuels or biochemical feedstocks, enhancing overall waste valorization efficiency.

Hydrothermal Carbonization

Hydrothermal carbonization (HTC) transforms wet biomass waste into biochar with high energy density, offering an efficient alternative to traditional waste-to-energy incineration that reduces harmful emissions and maximizes carbon capture. HTC biochar enhances soil fertility and sequesters carbon long-term, presenting a sustainable waste management solution compared to the rapid energy release and pollution concerns associated with conventional waste-to-energy methods.

Pyrolysis-Derived Biochar

Pyrolysis-derived biochar represents a sustainable waste management solution by converting organic waste into a stable carbon-rich material that enhances soil health and sequesters carbon, whereas Waste-to-Energy (WTE) processes focus on energy recovery from waste combustion, often releasing greenhouse gases. Unlike WTE, pyrolysis biochar production minimizes emissions and produces valuable byproducts such as bio-oil and syngas, supporting a circular economy and reducing environmental impact.

Circular Bioeconomy

Waste-to-Energy (WtE) plants convert municipal solid waste into electricity and heat, offering a scalable solution to reduce landfill use and greenhouse gas emissions while generating renewable energy. Biochar production enhances soil health and carbon sequestration by converting organic waste into a stable form of carbon, aligning with circular bioeconomy principles that prioritize resource recovery and sustainable land management.

Energy-Dense Biochar

Energy-dense biochar production offers a sustainable alternative to traditional waste-to-energy processes by converting organic waste into a carbon-rich, stable solid fuel that enhances soil health and sequesters carbon. Unlike conventional incineration, biochar provides long-term energy storage with lower emissions, promoting circular economy principles and reducing greenhouse gas outputs.

Anaerobic Digestion Residues

Anaerobic digestion residues from organic waste offer a valuable feedstock for both waste-to-energy processes and biochar production, with biochar providing enhanced soil amendment benefits and carbon sequestration potential. Waste-to-energy systems convert these residues into biogas for energy, whereas biochar production focuses on stabilizing organic matter and reducing greenhouse gas emissions over the long term.

Renewable Natural Gas (RNG) Integration

Waste-to-energy systems convert municipal solid waste into Renewable Natural Gas (RNG) through advanced gasification and anaerobic digestion, offering a scalable solution for renewable fuel integration. In contrast, biochar production stabilizes carbon in soil but requires supplementary processes to extract RNG, making waste-to-energy pathways more efficient for direct RNG generation.

Negative Emissions Technology (NET)

Waste-to-Energy (WtE) converts municipal solid waste into electricity, but often releases CO2 and other pollutants, limiting its effectiveness as a Negative Emissions Technology (NET). In contrast, biochar production sequesters carbon by pyrolyzing organic waste into stable carbon-rich material, offering a scalable NET solution that improves soil health and reduces greenhouse gas emissions.

Carbon-Negative Energy

Waste-to-energy processes convert organic waste into usable energy but often release significant carbon emissions, whereas biochar production sequesters carbon by transforming biomass into stable carbon-rich char, making it a genuinely carbon-negative energy solution. Biochar not only reduces greenhouse gases but also enhances soil fertility, promoting sustainable carbon management and long-term climate mitigation.

Co-Gasification Processes

Co-gasification processes enhance waste-to-energy conversion by simultaneously processing diverse waste streams, increasing syngas yield and energy efficiency compared to standalone biochar production. Integrating biochar extraction within co-gasification systems improves carbon sequestration while optimizing thermal output and reducing harmful emissions.

Waste-to-Energy vs Biochar Production Infographic

industrydif.com

industrydif.com