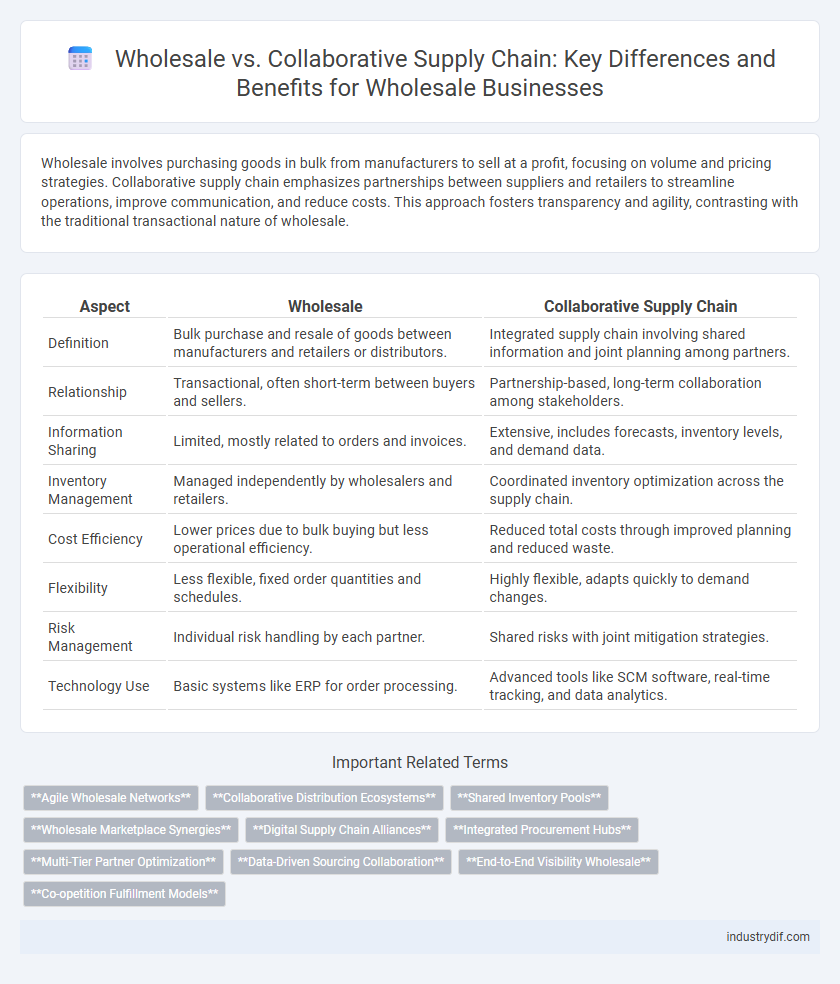

Wholesale involves purchasing goods in bulk from manufacturers to sell at a profit, focusing on volume and pricing strategies. Collaborative supply chain emphasizes partnerships between suppliers and retailers to streamline operations, improve communication, and reduce costs. This approach fosters transparency and agility, contrasting with the traditional transactional nature of wholesale.

Table of Comparison

| Aspect | Wholesale | Collaborative Supply Chain |

|---|---|---|

| Definition | Bulk purchase and resale of goods between manufacturers and retailers or distributors. | Integrated supply chain involving shared information and joint planning among partners. |

| Relationship | Transactional, often short-term between buyers and sellers. | Partnership-based, long-term collaboration among stakeholders. |

| Information Sharing | Limited, mostly related to orders and invoices. | Extensive, includes forecasts, inventory levels, and demand data. |

| Inventory Management | Managed independently by wholesalers and retailers. | Coordinated inventory optimization across the supply chain. |

| Cost Efficiency | Lower prices due to bulk buying but less operational efficiency. | Reduced total costs through improved planning and reduced waste. |

| Flexibility | Less flexible, fixed order quantities and schedules. | Highly flexible, adapts quickly to demand changes. |

| Risk Management | Individual risk handling by each partner. | Shared risks with joint mitigation strategies. |

| Technology Use | Basic systems like ERP for order processing. | Advanced tools like SCM software, real-time tracking, and data analytics. |

Defining Wholesale and Collaborative Supply Chain

Wholesale involves purchasing goods in large quantities directly from manufacturers to resell them at a profit, emphasizing inventory ownership and distribution efficiency. A collaborative supply chain integrates multiple stakeholders, including suppliers, manufacturers, and retailers, working closely to share information and optimize the entire supply process. The key distinction lies in wholesale focusing on bulk purchasing and resale, while collaborative supply chains prioritize partnership and real-time coordination for enhanced responsiveness.

Key Differences Between Wholesale and Collaborative Supply Chain

Wholesale centers on bulk purchasing and distribution, emphasizing volume discounts and inventory management to streamline product flow from manufacturers to retailers. Collaborative supply chains prioritize joint planning, shared resources, and transparent communication among partners to enhance efficiency and responsiveness. Key differences include the wholesale focus on transactional relationships and cost savings, whereas collaborative supply chains drive strategic partnerships and real-time data sharing for mutual benefit.

Advantages of Wholesale in Modern Markets

Wholesale offers significant advantages in modern markets by enabling bulk purchasing that reduces per-unit costs and improves profit margins. Streamlined inventory management through consolidated supplier relationships enhances operational efficiency and responsiveness to market demand. This traditional model ensures product availability and price stability, critical for retailers competing in fast-changing environments.

Benefits of Collaborative Supply Chain Models

Collaborative supply chain models enhance transparency and communication, leading to improved demand forecasting and inventory management compared to traditional wholesale approaches. By integrating suppliers, manufacturers, and retailers, these models reduce lead times and operational costs while increasing responsiveness to market changes. Shared data and joint decision-making foster innovation and strengthen supplier relationships, driving overall supply chain efficiency and customer satisfaction.

Cost Implications: Wholesale vs Collaborative Supply Chain

Wholesale supply chains typically involve bulk purchasing and standardized pricing structures that result in lower per-unit costs but higher inventory holding expenses. Collaborative supply chains emphasize shared information and coordinated planning, reducing waste and improving demand forecasting, which lowers overall supply chain costs. Cost implications favor collaborative models through enhanced efficiency and minimized risk, despite higher initial coordination investments.

Supply Chain Efficiency: Traditional vs Collaborative Approaches

Traditional wholesale supply chains often face inefficiencies due to fragmented communication, delayed information flow, and independent decision-making among suppliers, distributors, and retailers. Collaborative supply chain models enhance efficiency by fostering real-time data sharing, synchronized inventory management, and joint demand forecasting, reducing lead times and minimizing stockouts. Embracing collaboration leads to improved supply chain visibility, increased responsiveness, and optimized resource allocation across the entire distribution network.

Technology’s Role in Wholesale and Collaborative Supply Chains

Technology in wholesale leverages automation, real-time inventory management, and data analytics to optimize supply chain efficiency and reduce costs. Collaborative supply chains utilize cloud platforms, IoT, and AI-driven forecasting to enhance communication and transparency among partners, enabling agile decision-making and demand responsiveness. Integrating advanced technologies fosters synchronized operations, minimizes disruptions, and drives overall supply chain resilience in both wholesale and collaborative models.

Risk Management in Wholesale and Collaborative Supply Chains

Risk management in wholesale relies heavily on inventory control and demand forecasting to mitigate stockouts and overstock situations, which directly impact cash flow and profitability. Collaborative supply chains enhance risk management by promoting real-time information sharing and joint decision-making among partners, reducing uncertainties related to demand variability and supply disruptions. This integrated approach allows for more adaptive responses to market fluctuations, ultimately decreasing lead times and operational costs in wholesale distribution.

Market Trends Shaping Wholesale and Collaborative Supply Chains

Market trends such as digital transformation, increasing demand for real-time data, and a focus on sustainability are significantly shaping both wholesale and collaborative supply chains. Wholesale supply chains are evolving with automation and AI integration to optimize inventory management and reduce costs, while collaborative supply chains emphasize transparency and shared resources to improve resilience and agility. Growing consumer expectations for faster delivery and ethical sourcing drive innovation and closer partnerships across the supply chain ecosystem.

Choosing the Right Model: Factors for Businesses to Consider

Businesses must evaluate key factors such as inventory control, cost efficiency, and supplier relationships when choosing between wholesale and collaborative supply chain models. Wholesale typically offers high volume purchasing at lower prices but limits flexibility, while collaborative supply chains emphasize real-time communication and shared risk for improved responsiveness. Selecting the optimal model depends on company goals, market dynamics, and the need for supply chain agility versus cost savings.

Related Important Terms

Agile Wholesale Networks

Agile Wholesale Networks leverage real-time data integration and flexible supplier relationships to enhance responsiveness and minimize inventory costs in the wholesale sector. Emphasizing collaboration and rapid adaptation, these networks outperform traditional wholesale models by accelerating product flow and improving demand forecasting accuracy.

Collaborative Distribution Ecosystems

Collaborative distribution ecosystems in wholesale leverage real-time data sharing, joint forecasting, and synchronized logistics to enhance supply chain visibility and responsiveness. These ecosystems reduce inventory costs, improve delivery accuracy, and foster stronger partnerships between suppliers and retailers through integrated technology platforms.

Shared Inventory Pools

Shared inventory pools in wholesale enable multiple retailers to access and redistribute stock from a common warehouse, optimizing product availability and reducing stockouts. Collaborative supply chains enhance this concept by integrating real-time data sharing and joint demand forecasting, further improving inventory turnover and minimizing holding costs.

Wholesale Marketplace Synergies

Wholesale marketplaces drive synergies by integrating diverse supplier networks and centralized distribution channels, enhancing inventory turnover and reducing transaction costs. These platforms streamline demand forecasting and supply chain transparency, fostering collaboration that boosts operational efficiency and scalability in wholesale environments.

Digital Supply Chain Alliances

Digital supply chain alliances transform wholesale operations by integrating real-time data sharing, automated workflows, and predictive analytics to enhance inventory management and demand forecasting. These collaborative networks reduce lead times, optimize logistics, and increase transparency, driving cost efficiency and agile response across interconnected wholesale partners.

Integrated Procurement Hubs

Integrated procurement hubs in wholesale streamline supplier coordination by centralizing order management, reducing lead times and operational costs. Collaborative supply chains enhance this model by fostering real-time data sharing and joint demand forecasting among partners, driving efficiency and responsiveness.

Multi-Tier Partner Optimization

Multi-tier partner optimization in wholesale enhances supply chain efficiency by synchronizing inventory, demand forecasting, and logistics across manufacturers, distributors, and retailers. Leveraging advanced data analytics and real-time communication reduces costs, minimizes lead times, and improves service levels throughout the entire supply network.

Data-Driven Sourcing Collaboration

Data-driven sourcing collaboration in wholesale enables real-time sharing of demand forecasts, inventory levels, and supplier performance metrics, which optimizes procurement decisions and reduces supply chain disruptions. Leveraging advanced analytics and integrated platforms, wholesalers and suppliers improve transparency, drive cost efficiency, and enhance responsiveness across the supply chain.

End-to-End Visibility Wholesale

End-to-end visibility in wholesale enables real-time tracking of inventory, order status, and shipments across the entire supply chain, reducing delays and improving demand forecasting accuracy. Collaborative supply chains enhance this visibility by integrating data from multiple partners, fostering transparency and agility while minimizing disruptions in the wholesale distribution process.

Co-opetition Fulfillment Models

Wholesale operates under traditional supply chain dynamics emphasizing bulk purchasing and distribution efficiency, while collaborative supply chains leverage co-opetition fulfillment models that integrate cooperation among competing wholesalers to optimize inventory management and reduce costs. These co-opetition models enable shared resources, synchronized logistics, and real-time data exchange, fostering competitive advantage through collective efficiency and market responsiveness.

Wholesale vs Collaborative Supply Chain Infographic

industrydif.com

industrydif.com