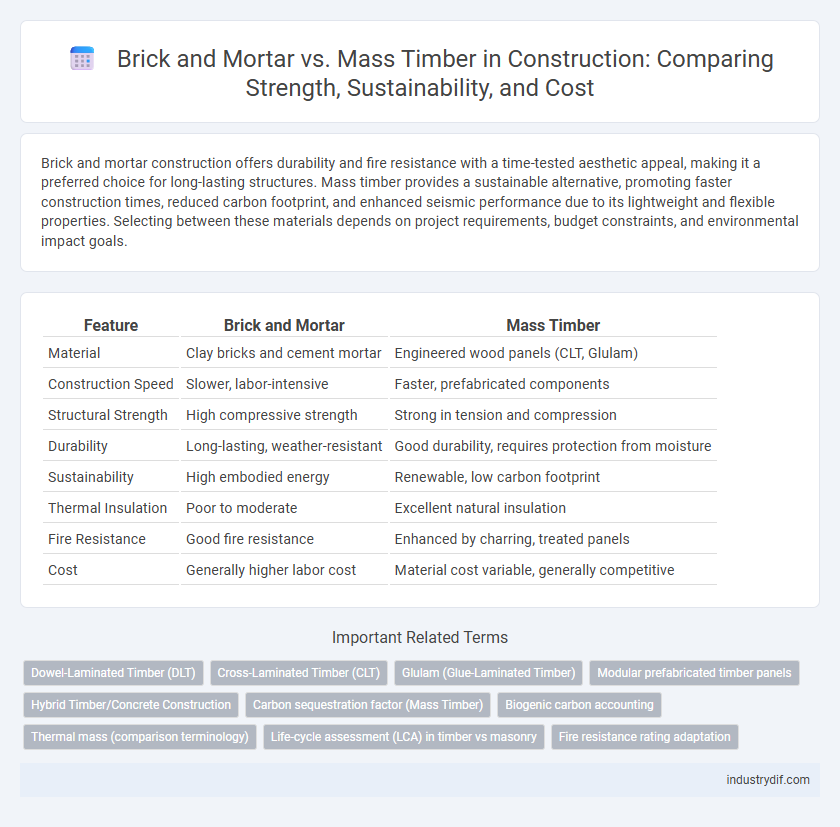

Brick and mortar construction offers durability and fire resistance with a time-tested aesthetic appeal, making it a preferred choice for long-lasting structures. Mass timber provides a sustainable alternative, promoting faster construction times, reduced carbon footprint, and enhanced seismic performance due to its lightweight and flexible properties. Selecting between these materials depends on project requirements, budget constraints, and environmental impact goals.

Table of Comparison

| Feature | Brick and Mortar | Mass Timber |

|---|---|---|

| Material | Clay bricks and cement mortar | Engineered wood panels (CLT, Glulam) |

| Construction Speed | Slower, labor-intensive | Faster, prefabricated components |

| Structural Strength | High compressive strength | Strong in tension and compression |

| Durability | Long-lasting, weather-resistant | Good durability, requires protection from moisture |

| Sustainability | High embodied energy | Renewable, low carbon footprint |

| Thermal Insulation | Poor to moderate | Excellent natural insulation |

| Fire Resistance | Good fire resistance | Enhanced by charring, treated panels |

| Cost | Generally higher labor cost | Material cost variable, generally competitive |

Introduction to Brick and Mortar and Mass Timber

Brick and mortar construction utilizes fired clay bricks bonded with mortar, offering durability, fire resistance, and thermal mass for energy efficiency. Mass timber involves large engineered wood panels like cross-laminated timber (CLT) and glued laminated timber (glulam), providing sustainable, lightweight, and fast-assembling alternatives with strong structural performance. Both methods serve distinct architectural and environmental needs, with brick and mortar excelling in permanence and mass timber advancing green building practices.

Historical Evolution of Building Materials

Brick and mortar construction, dating back to ancient Mesopotamia, has long been valued for its durability and fire resistance, while mass timber, rooted in traditional wood construction, has rapidly evolved with modern engineering techniques to offer sustainable and lightweight alternatives. Advances in mass timber technology, such as cross-laminated timber (CLT), have expanded its application in multi-story buildings, contrasting with the centuries-old reliance on masonry for structural stability. The historical evolution highlights a shift from labor-intensive, heavy materials toward engineered wood products that optimize strength, environmental impact, and construction speed.

Structural Performance Comparison

Brick and mortar structures offer high compressive strength and durability, making them ideal for load-bearing walls and longevity. Mass timber provides superior strength-to-weight ratio and flexibility, allowing for faster construction and better seismic performance. Both materials exhibit distinct advantages in structural performance, with brick and mortar excelling in fire resistance and mass timber delivering enhanced sustainability and seismic resilience.

Environmental Impact and Sustainability

Brick and mortar construction typically involves high carbon emissions due to energy-intensive brick firing and cement production for mortar, resulting in significant environmental impact. Mass timber offers a sustainable alternative by utilizing renewable wood resources and sequestering carbon throughout the building's lifecycle, reducing the overall carbon footprint. Lifecycle assessments confirm mass timber's potential to lower greenhouse gas emissions and support sustainable building practices compared to traditional masonry methods.

Cost Analysis: Initial Investment and Lifecycle

Brick and mortar construction typically requires a higher initial investment due to labor-intensive processes and material costs, whereas mass timber offers cost savings through faster assembly and prefabrication efficiencies. Lifecycle expenses for brick and mortar tend to be higher, driven by maintenance, repair, and energy consumption, while mass timber systems benefit from sustainability credits and lower operational costs due to their superior insulation properties. Evaluating both initial outlays and long-term financial impact reveals mass timber as a competitive alternative in cost-effective, sustainable construction projects.

Design Flexibility and Aesthetic Potential

Brick and mortar construction offers limited design flexibility due to its heavy and rigid nature, often restricting architectural creativity and intricate detailing. Mass timber provides enhanced aesthetic potential with its natural warmth, exposed wood grains, and the ability to create complex geometries through modular components. This material allows architects to explore innovative designs while maintaining structural integrity and sustainability.

Construction Speed and Labor Requirements

Mass timber construction significantly accelerates project timelines due to prefabricated panels that reduce onsite assembly time compared to traditional brick and mortar methods. Labor requirements for mass timber are typically lower, relying on fewer skilled workers and minimizing heavy masonry work. Brick and mortar construction demands extensive manual labor and longer curing periods, which contribute to slower overall progress and higher labor costs.

Fire Resistance and Safety Considerations

Brick and mortar construction offers superior fire resistance due to its non-combustible materials, effectively containing fire and preventing structural collapse. Mass timber, while engineered for enhanced fire performance through charring that protects inner cores, requires additional fire-retardant treatments and compliance with strict building codes to ensure safety. Fire safety considerations in choosing between these materials depend on factors like building height, occupancy type, and local fire regulations, with brick providing inherent fireproofing and mass timber balancing sustainability with engineered fire resistance.

Regulatory Standards and Building Codes

Brick and Mortar construction is governed by well-established regulatory standards that emphasize fire resistance, structural integrity, and durability, often codified in international, national, and local building codes such as the International Building Code (IBC) and Eurocode. Mass Timber construction faces evolving regulatory frameworks that address sustainability, seismic performance, and fire safety, with standards like the ANSI/APA PRG 320 for Cross-Laminated Timber and updated provisions in the IBC supporting taller timber structures. Compliance with these building codes requires rigorous testing and certification to ensure that mass timber meets or exceeds the safety and performance benchmarks traditionally associated with brick and mortar construction.

Future Trends in Commercial and Residential Construction

Future trends in commercial and residential construction emphasize sustainability, with mass timber gaining prominence due to its renewable properties, carbon sequestration, and faster build times compared to traditional brick and mortar. Innovations in engineered wood products, such as cross-laminated timber (CLT) and glued laminated timber (glulam), enable taller and more complex structures, challenging the dominance of masonry. Regulatory shifts and increasing environmental standards drive the adoption of mass timber as a preferred material for green building certifications and energy-efficient design.

Related Important Terms

Dowel-Laminated Timber (DLT)

Dowel-Laminated Timber (DLT) offers a sustainable alternative to traditional brick and mortar by providing high structural integrity through the use of hardwood dowels instead of metal fasteners, enhancing seismic performance and reducing carbon footprint. DLT panels enable faster on-site assembly and improved thermal insulation, making mass timber construction a cost-effective and energy-efficient solution in modern building projects.

Cross-Laminated Timber (CLT)

Cross-Laminated Timber (CLT) offers superior sustainability and faster construction timelines compared to traditional brick and mortar, leveraging engineered wood panels with high strength-to-weight ratios and excellent thermal insulation properties. CLT's prefabrication reduces onsite waste and labor costs, making it a cost-effective solution for mid-rise buildings while maintaining structural integrity and fire resistance.

Glulam (Glue-Laminated Timber)

Glulam, or glue-laminated timber, offers superior strength-to-weight ratio and design flexibility compared to traditional brick and mortar, enabling faster construction and reduced environmental impact through sustainable sourcing. Its engineered layers provide enhanced structural integrity and resistance to seismic forces, making glulam a preferred choice for modern mass timber buildings aiming for durability and aesthetic appeal.

Modular prefabricated timber panels

Modular prefabricated timber panels offer superior sustainability and speed in construction compared to traditional brick and mortar methods, reducing on-site labor and waste through precision manufacturing. Mass timber panels provide enhanced thermal performance and seismic resilience, promoting greener building practices while accelerating project timelines in commercial and residential developments.

Hybrid Timber/Concrete Construction

Hybrid timber/concrete construction combines the durability and fire resistance of concrete with the sustainability and aesthetic appeal of mass timber, optimizing structural performance and environmental impact. This approach enhances seismic resilience and reduces construction time while maintaining strength and thermal efficiency in building projects.

Carbon sequestration factor (Mass Timber)

Mass timber construction significantly enhances carbon sequestration by storing large amounts of CO2 within the wood fibers, reducing overall carbon emissions compared to traditional brick and mortar methods that rely on energy-intensive materials like concrete and fired bricks. This sustainable attribute makes mass timber a vital strategy for lowering the carbon footprint in the building industry.

Biogenic carbon accounting

Mass timber construction significantly reduces biogenic carbon emissions compared to traditional brick and mortar methods by storing carbon within wood fibers, which can offset fossil fuel-based emissions over the building's lifecycle. In contrast, brick and mortar materials typically involve higher embodied carbon from energy-intensive production processes and do not provide substantial carbon sequestration benefits.

Thermal mass (comparison terminology)

Brick and mortar construction exhibits high thermal mass, absorbing and slowly releasing heat to regulate indoor temperatures effectively, while mass timber offers moderate thermal mass with superior insulation properties but less heat retention capacity. This difference impacts energy efficiency strategies, as brick and mortar structures reduce temperature fluctuations, whereas mass timber emphasizes faster thermal response times and renewable material benefits.

Life-cycle assessment (LCA) in timber vs masonry

Mass timber demonstrates a lower environmental impact and carbon footprint in life-cycle assessments compared to traditional brick and mortar due to its renewable sourcing and carbon sequestration properties. Masonry materials typically involve higher embodied energy and emissions from extraction, processing, and transportation, resulting in less sustainable long-term performance.

Fire resistance rating adaptation

Brick and mortar constructions typically offer superior fire resistance ratings due to their non-combustible materials, with walls often rated for two to four hours of fire endurance. In contrast, mass timber buildings achieve fire resistance through thick, char-resistant layers that can provide up to two-hour fire ratings, supported by modern fire-retardant treatments and engineered design standards.

Brick and Mortar vs Mass Timber Infographic

industrydif.com

industrydif.com