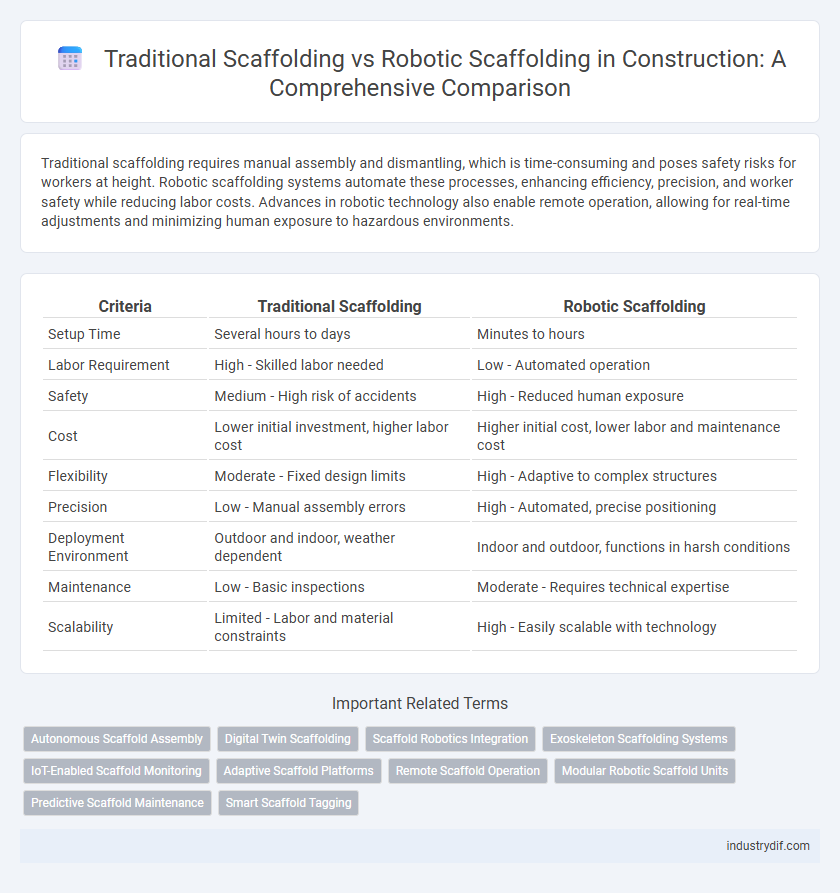

Traditional scaffolding requires manual assembly and dismantling, which is time-consuming and poses safety risks for workers at height. Robotic scaffolding systems automate these processes, enhancing efficiency, precision, and worker safety while reducing labor costs. Advances in robotic technology also enable remote operation, allowing for real-time adjustments and minimizing human exposure to hazardous environments.

Table of Comparison

| Criteria | Traditional Scaffolding | Robotic Scaffolding |

|---|---|---|

| Setup Time | Several hours to days | Minutes to hours |

| Labor Requirement | High - Skilled labor needed | Low - Automated operation |

| Safety | Medium - High risk of accidents | High - Reduced human exposure |

| Cost | Lower initial investment, higher labor cost | Higher initial cost, lower labor and maintenance cost |

| Flexibility | Moderate - Fixed design limits | High - Adaptive to complex structures |

| Precision | Low - Manual assembly errors | High - Automated, precise positioning |

| Deployment Environment | Outdoor and indoor, weather dependent | Indoor and outdoor, functions in harsh conditions |

| Maintenance | Low - Basic inspections | Moderate - Requires technical expertise |

| Scalability | Limited - Labor and material constraints | High - Easily scalable with technology |

Introduction to Scaffolding in Construction

Scaffolding in construction serves as a temporary structure supporting workers and materials during building or repair projects, ensuring safety and accessibility at various heights. Traditional scaffolding consists of manual assembly using metal tubes and wooden platforms, relying heavily on skilled labor for setup and adjustments. Robotic scaffolding introduces automated systems that enhance efficiency, reduce human error, and improve safety by using sensors and robotics to accelerate construction timelines and minimize manual risks.

Overview of Traditional Scaffolding Systems

Traditional scaffolding systems rely on metal tubes and couplers assembled manually to create temporary structures supporting workers and materials during construction. These systems are favored for their flexibility, cost-effectiveness, and compatibility with irregular building shapes but require significant labor and time for setup and dismantling. Safety risks and the physical demands of manual assembly often lead to higher injury rates compared to automated solutions.

Advancements in Robotic Scaffolding Technology

Robotic scaffolding technology integrates automated systems with precise sensors and AI algorithms, enhancing safety and efficiency on construction sites compared to traditional scaffolding. Advanced robotic platforms enable rapid assembly, real-time monitoring, and adaptive adjustments to structural requirements, reducing manual labor and minimizing human error. Innovations such as autonomous drones and AI-driven cranes further optimize material handling and structure inspections within robotic scaffolding systems.

Installation Processes: Manual vs Automated

Traditional scaffolding installation relies heavily on manual labor, requiring skilled workers to assemble and secure components incrementally, which can be time-consuming and labor-intensive. Robotic scaffolding utilizes automated systems and robotics technology to streamline the setup process, significantly reducing on-site human intervention and enhancing precision and safety. The automation in robotic scaffolding installation accelerates project timelines and minimizes risks associated with manual assembly at height.

Safety Standards and Risk Management

Traditional scaffolding relies heavily on manual labor, increasing the risk of falls and structural failures due to human error, whereas robotic scaffolding employs automated systems with advanced sensors and real-time monitoring to enhance safety. Robotic scaffolding integrates strict compliance with OSHA and ANSI safety standards, reducing workplace accidents and improving risk management through precise construction and remote operation capabilities. Implementing robotic scaffolding minimizes exposure to hazardous environments, thereby significantly lowering injury rates and promoting safer construction site conditions.

Cost Comparison: Labor and Material Efficiency

Traditional scaffolding involves higher labor costs due to manual assembly and disassembly processes, which also increase project timelines and material waste. Robotic scaffolding systems optimize labor efficiency by automating setup and adjustments, significantly reducing workforce requirements and minimizing scaffold material usage through precise placement. Cost analysis reveals robotic scaffolding lowers overall expenses by cutting labor hours by up to 40% and reducing material consumption by improving scaffold design accuracy.

Project Timelines and Productivity

Traditional scaffolding often extends project timelines due to manual assembly and limited flexibility in adjustments, which can slow down productivity on-site. Robotic scaffolding leverages automated systems to expedite setup and modifications, significantly reducing labor time and enhancing workflow efficiency. This technological advancement directly accelerates project completion and boosts overall productivity in construction operations.

Environmental Impact and Sustainability

Traditional scaffolding relies heavily on metal and timber materials, often resulting in considerable waste and increased carbon emissions during manufacturing and disposal. Robotic scaffolding systems utilize lightweight, reusable components and automated assembly, significantly reducing material consumption and minimizing environmental footprint. Enhanced efficiency and precision in robotic scaffolding lower energy use on-site, promoting greater sustainability in construction projects.

Workforce Skills and Training Requirements

Traditional scaffolding relies heavily on manual labor, requiring workers to have specialized skills in assembling and securing scaffolding structures safely, which often involves comprehensive on-site training and certification. Robotic scaffolding minimizes the need for manual assembly by automating tasks, thus shifting workforce requirements toward technical expertise in operating, programming, and maintaining robotic systems, leading to a demand for advanced training in robotics and automation technologies. The transition to robotic scaffolding enhances safety but necessitates a workforce proficient in digital tools and mechanical troubleshooting, reducing physical risks while increasing the importance of continuous education in emerging technologies.

Future Trends in Scaffolding Solutions

Robotic scaffolding is revolutionizing construction by integrating automation, enhancing precision, and reducing labor costs compared to traditional scaffolding methods. Future trends emphasize the adoption of AI-powered scaffolding systems that improve safety standards through real-time monitoring and adaptive stability controls. Smart materials and modular robotic components are expected to accelerate project timelines while minimizing environmental impact in scaffolding solutions.

Related Important Terms

Autonomous Scaffold Assembly

Autonomous scaffold assembly leverages robotic scaffolding systems equipped with advanced sensors and AI algorithms to enhance precision and reduce labor costs compared to traditional scaffolding methods. This technology accelerates construction timelines by enabling self-directed scaffold erection and disassembly, improving safety and minimizing human error on site.

Digital Twin Scaffolding

Digital Twin Scaffolding integrates advanced sensor technologies and real-time data analytics to create an exact virtual replica of the physical scaffold, enhancing safety and efficiency beyond traditional scaffolding methods. This digital ecosystem enables proactive maintenance, precise load management, and seamless remote monitoring, revolutionizing construction site operations.

Scaffold Robotics Integration

Scaffold robotics integration revolutionizes traditional scaffolding by enhancing safety, precision, and efficiency through automated assembly and real-time monitoring, reducing manual labor and human error. This advanced technology leverages AI-driven robots and sensor networks to streamline complex construction projects, enabling faster build times and improved structural integrity.

Exoskeleton Scaffolding Systems

Exoskeleton scaffolding systems enhance worker mobility and safety by integrating wearable robotic frameworks that support weight and reduce fatigue, outperforming traditional scaffolding in efficiency and ergonomics. These advanced systems enable quicker assembly and disassembly while minimizing fall risks, transforming construction site operations through improved structural support and dynamic adaptability.

IoT-Enabled Scaffold Monitoring

IoT-enabled scaffold monitoring in robotic scaffolding offers real-time data on structural integrity, worker safety, and environmental conditions, outperforming traditional scaffolding's manual inspection methods. This integration reduces downtime, enhances preventive maintenance, and improves overall site productivity through automated alerts and detailed analytics.

Adaptive Scaffold Platforms

Adaptive scaffold platforms in construction leverage robotic scaffolding technology to enhance safety, precision, and efficiency by automatically adjusting to complex building geometries and environmental conditions. Traditional scaffolding relies on manual assembly and fixed configurations, often resulting in longer setup times and increased risk, whereas robotic systems utilize sensors and programmable controls to optimize platform positioning and worker access dynamically.

Remote Scaffold Operation

Remote scaffold operation enhances construction safety by enabling workers to control robotic scaffolding systems from a distance, reducing the risk of falls and accidents associated with traditional scaffolding setups. This technology integrates advanced sensors and automation, allowing precise positioning and real-time monitoring, which optimizes project efficiency and minimizes on-site labor requirements.

Modular Robotic Scaffold Units

Modular robotic scaffold units revolutionize traditional scaffolding by offering automated assembly, enhanced safety features, and adaptability to complex construction sites, reducing labor costs and construction timelines. These units integrate advanced sensors and AI-driven controls to ensure precise positioning and real-time monitoring, significantly improving efficiency and risk management compared to conventional scaffold systems.

Predictive Scaffold Maintenance

Predictive scaffold maintenance in traditional scaffolding relies heavily on manual inspections and scheduled checks, often leading to unexpected downtime and safety risks. Robotic scaffolding integrates IoT sensors and AI-driven analytics to continuously monitor structural integrity, enabling real-time detection of wear and potential failures, significantly enhancing safety and operational efficiency.

Smart Scaffold Tagging

Smart scaffold tagging in robotic scaffolding enhances real-time monitoring, safety compliance, and inventory management, significantly reducing human error compared to traditional scaffolding methods. This technology integrates IoT sensors and RFID tags to provide precise data on scaffold usage, structural integrity, and worker presence, optimizing construction site efficiency and safety.

Traditional Scaffolding vs Robotic Scaffolding Infographic

industrydif.com

industrydif.com