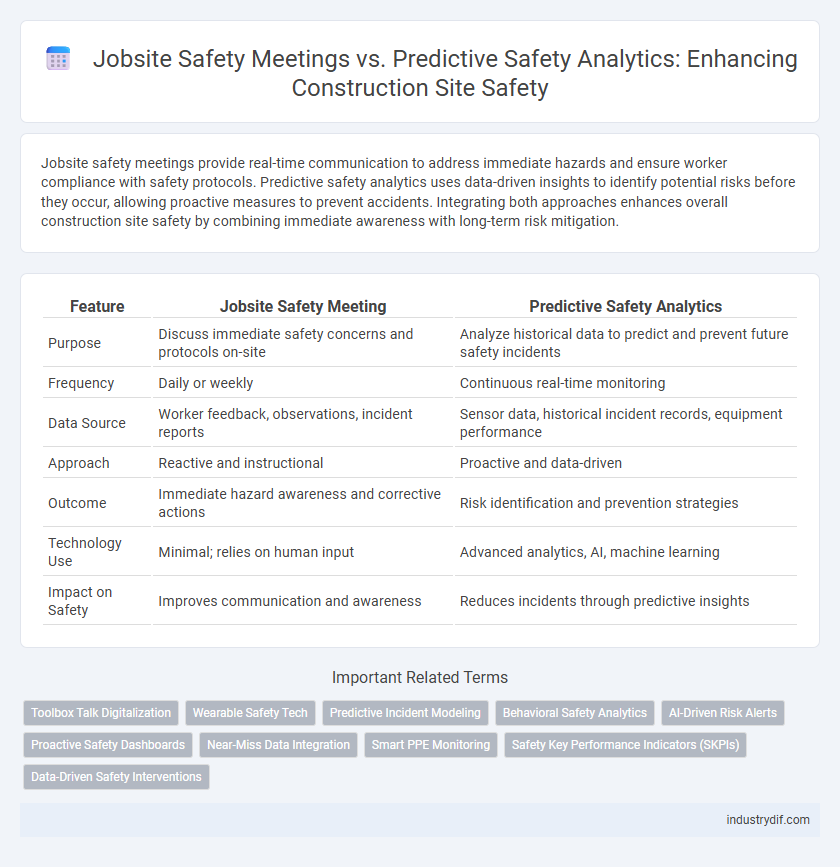

Jobsite safety meetings provide real-time communication to address immediate hazards and ensure worker compliance with safety protocols. Predictive safety analytics uses data-driven insights to identify potential risks before they occur, allowing proactive measures to prevent accidents. Integrating both approaches enhances overall construction site safety by combining immediate awareness with long-term risk mitigation.

Table of Comparison

| Feature | Jobsite Safety Meeting | Predictive Safety Analytics |

|---|---|---|

| Purpose | Discuss immediate safety concerns and protocols on-site | Analyze historical data to predict and prevent future safety incidents |

| Frequency | Daily or weekly | Continuous real-time monitoring |

| Data Source | Worker feedback, observations, incident reports | Sensor data, historical incident records, equipment performance |

| Approach | Reactive and instructional | Proactive and data-driven |

| Outcome | Immediate hazard awareness and corrective actions | Risk identification and prevention strategies |

| Technology Use | Minimal; relies on human input | Advanced analytics, AI, machine learning |

| Impact on Safety | Improves communication and awareness | Reduces incidents through predictive insights |

Overview of Jobsite Safety Meetings

Jobsite safety meetings are critical for reinforcing workplace protocols, discussing hazard identifications, and ensuring worker compliance with safety regulations. These meetings typically involve direct communication between managers and workers to review recent incidents, update safety procedures, and promote a culture of proactive risk management. Regular jobsite safety meetings contribute significantly to reducing accidents and improving overall construction site safety performance.

Introduction to Predictive Safety Analytics

Predictive safety analytics uses data-driven algorithms to identify potential hazards on construction sites before they occur, enhancing traditional jobsite safety meetings by providing proactive risk management. By analyzing historical incident reports, worker behavior, and environmental conditions, this technology enables real-time insights that improve decision-making and reduce accidents. Integrating predictive safety analytics into construction safety protocols helps optimize resource allocation and strengthens overall site safety performance.

Key Differences Between Traditional and Predictive Safety Approaches

Jobsite safety meetings rely on historical incident data and worker feedback to address immediate hazards through communication and training. Predictive safety analytics uses real-time data from sensors, wearables, and AI algorithms to forecast potential risks and proactively prevent accidents. The key difference lies in the shift from reactive, periodic safety checks to continuous, data-driven risk management in construction environments.

Benefits of Regular Jobsite Safety Meetings

Regular jobsite safety meetings significantly enhance workplace hazard awareness by fostering real-time communication and immediate feedback among construction teams. Consistent meetings promote a proactive safety culture, reducing accident rates and improving compliance with OSHA regulations. These gatherings ensure that safety protocols are continuously reinforced, leading to higher employee engagement and a safer jobsite environment.

Advantages of Implementing Predictive Safety Analytics

Predictive safety analytics in construction leverages real-time data and machine learning algorithms to identify potential hazards before they occur, significantly reducing workplace accidents. Unlike traditional jobsite safety meetings, which rely on retrospective analysis and human observation, predictive analytics provides continuous risk assessment and proactive intervention. Implementing predictive safety analytics enhances accuracy in hazard identification, optimizes resource allocation, and improves overall safety performance on construction sites.

Integrating Predictive Technology with Safety Meetings

Integrating predictive safety analytics into jobsite safety meetings enhances hazard identification by leveraging real-time data and machine learning algorithms to forecast potential risks before they occur. This fusion allows construction teams to proactively address safety concerns, reducing incidents and improving compliance with OSHA standards. Using advanced predictive technology during safety discussions promotes a culture of continuous improvement and data-driven decision-making on construction sites.

Data Collection in Construction Safety Practices

Jobsite safety meetings rely on real-time observations and worker feedback to identify hazards, while predictive safety analytics use data collection from sensors, wearables, and historical incident reports to forecast potential risks. Incorporating predictive analytics enhances construction safety practices by analyzing trends and enabling proactive interventions before incidents occur. Data collection through IoT devices and digital platforms provides comprehensive insights that improve hazard identification beyond traditional safety meeting discussions.

Impact on Incident Reduction and Risk Management

Jobsite safety meetings provide immediate hazard communication and compliance reinforcement, directly reducing incidents through real-time awareness. Predictive safety analytics leverage historical data and machine learning to identify potential risks before they manifest, enabling proactive risk management strategies. Combining traditional meetings with predictive analytics enhances incident reduction by transforming reactive safety practices into data-driven prevention models.

Challenges in Adopting Predictive Safety Solutions

Predictive safety analytics in construction face challenges such as high implementation costs, data integration complexities, and workforce resistance to new technologies. Jobsite safety meetings remain a traditional method owing to their direct communication and immediate feedback, but they lack the proactivity offered by predictive solutions. Overcoming these adoption barriers requires combining real-time data processing with effective change management strategies to enhance overall safety outcomes.

Future Trends in Construction Site Safety

Jobsite safety meetings provide immediate hazard awareness through on-site communication, while predictive safety analytics leverage real-time data and machine learning to forecast and prevent potential accidents. Future trends in construction site safety emphasize integrating predictive analytics with IoT sensors and wearable technology to enable proactive risk management and enhance worker protection. The adoption of AI-driven safety platforms will transform traditional jobsite protocols by offering dynamic, data-driven insights that reduce incidents and improve compliance.

Related Important Terms

Toolbox Talk Digitalization

Jobsite safety meetings, traditionally conducted through in-person toolbox talks, are undergoing digital transformation by integrating predictive safety analytics to proactively identify and mitigate risks before incidents occur. Leveraging real-time data and machine learning algorithms enhances the effectiveness of safety discussions, enabling construction teams to shift from reactive compliance to proactive hazard prevention.

Wearable Safety Tech

Wearable safety tech enhances jobsite safety meetings by providing real-time data on worker movements and environmental hazards, enabling predictive safety analytics to identify risks before accidents occur. Integrating sensor-equipped wearables with predictive models reduces workplace injuries and optimizes safety protocols on construction sites.

Predictive Incident Modeling

Predictive incident modeling leverages advanced data analytics and machine learning algorithms to foresee potential hazards on construction sites, enabling proactive measures that significantly reduce accident rates. Unlike traditional jobsite safety meetings that rely on reactive communication, predictive safety analytics integrates real-time data to identify risk patterns, enhancing overall safety management and compliance.

Behavioral Safety Analytics

Behavioral safety analytics uses data-driven insights to predict and prevent workplace incidents by analyzing patterns in employee behavior, enhancing traditional jobsite safety meetings that primarily focus on hazard communication and compliance. Integrating predictive safety analytics with regular safety meetings fosters a proactive safety culture, reducing accidents through targeted interventions based on real behavioral data.

AI-Driven Risk Alerts

Jobsite safety meetings provide essential real-time communication on hazards, but AI-driven predictive safety analytics enhance risk management by continuously analyzing data to generate proactive risk alerts, reducing incidents before they occur. Integrating machine learning algorithms with sensor data and historical injury records enables construction firms to identify patterns and potential threats, significantly improving on-site decision-making and worker protection.

Proactive Safety Dashboards

Proactive safety dashboards integrate predictive safety analytics to identify potential hazards before they occur, enhancing traditional jobsite safety meetings by providing real-time, data-driven insights. This approach improves risk management by enabling construction managers to monitor trends and implement preventive measures, reducing workplace incidents efficiently.

Near-Miss Data Integration

Integrating near-miss data into predictive safety analytics enhances the accuracy of hazard identification by analyzing real-time jobsite safety meeting reports and incident patterns. This synergy allows construction managers to proactively mitigate risks and improve overall site safety performance through data-driven decision-making.

Smart PPE Monitoring

Jobsite safety meetings provide essential real-time communication about hazards, while predictive safety analytics leverage data from smart PPE monitoring to proactively identify risks before incidents occur. Integrating smart PPE sensors with predictive analytics enhances jobsite safety by continuously tracking worker health and environmental conditions, reducing accidents through early hazard detection.

Safety Key Performance Indicators (SKPIs)

Jobsite safety meetings provide real-time hazard identification and worker engagement, directly impacting Safety Key Performance Indicators (SKPIs) such as incident rates and near-miss frequency. Predictive safety analytics enhance SKPIs by leveraging historical data and machine learning models to forecast potential risks, enabling proactive interventions that reduce accidents and improve overall jobsite safety performance.

Data-Driven Safety Interventions

Jobsite safety meetings rely on real-time observations and immediate hazard discussions to prevent accidents, while predictive safety analytics leverages historical data and machine learning algorithms to identify patterns and forecast potential risks, enabling proactive, data-driven safety interventions. Integrating predictive analytics into construction safety programs enhances risk mitigation by targeting high-risk activities before incidents occur, improving overall jobsite safety outcomes.

Jobsite Safety Meeting vs Predictive Safety Analytics Infographic

industrydif.com

industrydif.com