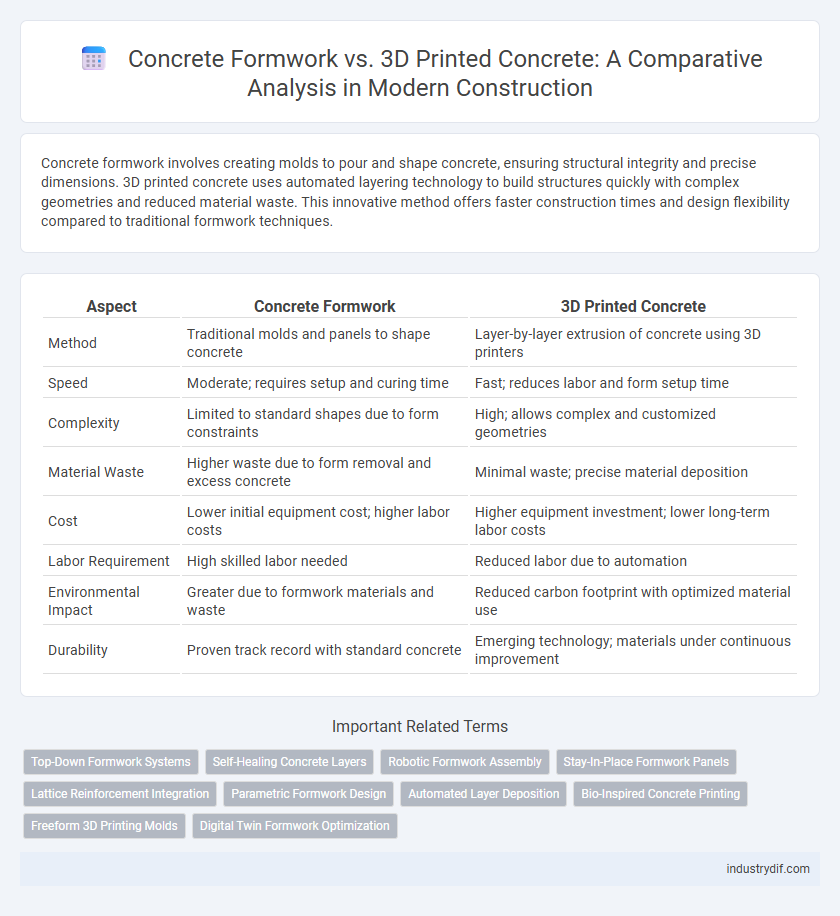

Concrete formwork involves creating molds to pour and shape concrete, ensuring structural integrity and precise dimensions. 3D printed concrete uses automated layering technology to build structures quickly with complex geometries and reduced material waste. This innovative method offers faster construction times and design flexibility compared to traditional formwork techniques.

Table of Comparison

| Aspect | Concrete Formwork | 3D Printed Concrete |

|---|---|---|

| Method | Traditional molds and panels to shape concrete | Layer-by-layer extrusion of concrete using 3D printers |

| Speed | Moderate; requires setup and curing time | Fast; reduces labor and form setup time |

| Complexity | Limited to standard shapes due to form constraints | High; allows complex and customized geometries |

| Material Waste | Higher waste due to form removal and excess concrete | Minimal waste; precise material deposition |

| Cost | Lower initial equipment cost; higher labor costs | Higher equipment investment; lower long-term labor costs |

| Labor Requirement | High skilled labor needed | Reduced labor due to automation |

| Environmental Impact | Greater due to formwork materials and waste | Reduced carbon footprint with optimized material use |

| Durability | Proven track record with standard concrete | Emerging technology; materials under continuous improvement |

Introduction to Concrete Formwork and 3D Printed Concrete

Concrete formwork traditionally relies on assembled molds made from wood, steel, or plastic to shape and support poured concrete until it hardens. In contrast, 3D printed concrete uses robotic additive manufacturing to layer material precisely, enabling complex designs and reducing material waste. Both techniques play crucial roles in modern construction, with formwork offering versatility and 3D printing providing innovation in design and efficiency.

Key Differences Between Traditional Formwork and 3D Printing

Traditional concrete formwork requires extensive labor, material costs, and time for setup and removal, relying on wooden or metal molds to shape concrete. In contrast, 3D printed concrete eliminates the need for form molds by extruding layers of concrete through a nozzle, enabling complex geometries and faster construction timelines. The precision and automation in 3D printing reduce material waste, improve design flexibility, and streamline project workflows compared to conventional formwork methods.

Material Properties and Compatibility

Concrete formwork relies on traditional materials such as wood, steel, or plastic, offering high compressive strength and durability that support precise shaping during curing. In contrast, 3D printed concrete utilizes specialized, fast-setting mixes with enhanced flowability and reduced aggregate size to ensure layer adhesion and structural integrity without formwork. Compatibility with reinforcement varies; conventional formwork easily integrates with steel rebar, whereas 3D printed methods often require incorporating fibers or novel reinforcement techniques to maintain tensile strength.

Speed and Efficiency in Construction

Concrete formwork requires significant labor and time for setup and removal, limiting construction speed. In contrast, 3D printed concrete drastically reduces formwork time by directly depositing material layer-by-layer, enhancing efficiency. This technology accelerates project timelines and lowers labor costs, making it a transformative solution in modern construction.

Labor Requirements and Skill Sets

Concrete formwork demands skilled carpenters and labor-intensive setup involving precise measurements and manual assembly, resulting in higher labor costs and extended timelines. In contrast, 3D printed concrete reduces labor requirements significantly by automating the building process, requiring operators trained in digital fabrication and 3D printing technology. The shift towards 3D printing in construction involves a transition from traditional craftsmanship to specialized technical expertise in software and machine operation.

Cost Considerations and Budget Impact

Concrete formwork requires significant labor and materials, resulting in higher upfront costs and extended project timelines. 3D printed concrete minimizes the need for formwork and manual labor, reducing construction expenses and accelerating build speed. Budget impact favors 3D printing for projects aiming to optimize cost efficiency through automation and material savings.

Design Flexibility and Architectural Limits

Concrete formwork offers traditional design flexibility with customizable molds for various shapes but is constrained by the complexity and cost of intricate forms. 3D printed concrete surpasses these limits by enabling highly complex, free-form architectural designs without the need for extensive molds or formwork, significantly reducing material waste and labor. This technology expands architectural possibilities, allowing for innovative structures that were previously impractical or too costly with conventional formwork.

Environmental Impact and Sustainability

Concrete formwork generates significant waste through single-use plywood and metal materials, contributing to deforestation and landfill issues, whereas 3D printed concrete minimizes material use by precisely depositing only the necessary amount, reducing overall resource consumption. The lower energy demand and decreased carbon footprint of 3D printed concrete, achieved through automated processes and optimized geometry designs, enhance sustainability compared to traditional formwork methods reliant on energy-intensive fabrication and transportation. Embracing 3D printed concrete supports green construction practices by cutting raw material waste, lowering CO2 emissions, and enabling complex, resilient structures with reduced environmental impact.

Structural Performance and Quality Control

Concrete formwork offers consistent structural performance through established mold designs, ensuring uniform load distribution and surface finish, while 3D printed concrete enables complex geometries with reduced material waste and precise layer-by-layer deposition that enhances structural integrity at critical points. Quality control in traditional formwork depends on accurate mold fabrication and skilled labor to avoid defects, whereas 3D printing integrates real-time monitoring and automation, significantly reducing human error and improving material consistency. Both methods present unique advantages in durability and precision, but 3D printed concrete is rapidly advancing with digital controls that optimize structural performance beyond conventional limitations.

Future Trends in Concrete Construction Technologies

Concrete formwork remains essential for shaping and supporting conventional cast-in-place concrete structures, offering versatility and reliability in varied construction scenarios. 3D printed concrete leverages additive manufacturing technology to enable rapid, precise, and complex architectural designs with reduced material waste and labor costs. Future trends in concrete construction technologies emphasize integrating 3D printing with smart sensors and sustainable materials to enhance efficiency, durability, and environmental impact.

Related Important Terms

Top-Down Formwork Systems

Top-down formwork systems enhance construction efficiency by enabling simultaneous slab casting and structural support erection, reducing cycle time and labor costs in traditional concrete formwork. In contrast, 3D printed concrete eliminates formwork entirely by layering material digitally, offering design flexibility and minimizing material waste, but currently faces challenges in scalability and structural reinforcement integration.

Self-Healing Concrete Layers

Concrete formwork traditionally shapes and supports concrete until it cures, while 3D printed concrete leverages advanced layering techniques to enable self-healing properties through embedded microcapsules or bacteria in the mix. Self-healing concrete layers in 3D printing enhance durability by autonomously sealing cracks, reducing maintenance costs, and extending the lifespan of structures compared to conventional formwork methods.

Robotic Formwork Assembly

Robotic formwork assembly in concrete construction offers precise, rapid installation with minimal human error, enhancing efficiency compared to traditional concrete formwork methods. Unlike 3D printed concrete that extrudes material layer by layer, robotic formwork enables complex geometric shaping through automated mold setup, allowing seamless integration of reinforcement and embedded systems.

Stay-In-Place Formwork Panels

Stay-in-place formwork panels in traditional concrete construction provide structural support and act as permanent molds, enhancing durability and reducing labor time compared to removable forms. In contrast, 3D printed concrete eliminates the need for formwork entirely by directly depositing material layer-by-layer, enabling complex designs and material efficiency but currently lacks integrated stay-in-place panel benefits.

Lattice Reinforcement Integration

Concrete formwork provides a traditional framework for integrating lattice reinforcement, ensuring structural stability through precise placement and support during curing. In contrast, 3D printed concrete enables the direct embedding of complex lattice reinforcements within the printed layers, offering enhanced material efficiency and design flexibility.

Parametric Formwork Design

Parametric formwork design leverages computational algorithms to create highly customizable and precise concrete molds, enhancing the efficiency and complexity of traditional concrete formwork in construction. Compared to 3D printed concrete, parametric formwork enables large-scale production with smooth surface finishes and structural integrity, while 3D printing offers rapid prototyping and intricate geometric possibilities without the need for physical molds.

Automated Layer Deposition

Automated layer deposition in 3D printed concrete enables precise, customizable structural designs with minimal material waste, contrasting traditional concrete formwork which relies on manual assembly and rigid molds. This digital fabrication technique significantly reduces labor costs and construction time while enhancing architectural complexity and sustainability in building projects.

Bio-Inspired Concrete Printing

Bio-inspired concrete printing in 3D construction advances traditional concrete formwork by mimicking natural structures to optimize material distribution and enhance structural resilience. This method reduces waste, shortens build times, and enables complex geometries that conventional formwork cannot achieve efficiently.

Freeform 3D Printing Molds

Freeform 3D printing molds revolutionize concrete formwork by enabling precise customization of complex geometries that traditional methods struggle to achieve, enhancing design flexibility and reducing labor costs. These advanced molds improve surface finish quality and accelerate construction timelines by minimizing the need for manual adjustments and formwork assembly.

Digital Twin Formwork Optimization

Digital twin formwork optimization leverages real-time data and simulation to enhance accuracy and reduce material waste in both concrete formwork and 3D printed concrete applications. Integrating digital twins with 3D printed concrete allows precise control over complex geometries, accelerating construction timelines and improving structural performance compared to traditional formwork methods.

Concrete Formwork vs 3D Printed Concrete Infographic

industrydif.com

industrydif.com