Building Information Modeling (BIM) provides a detailed digital representation of a building's physical and functional characteristics during the design and construction phases. Digital Twin technology extends beyond BIM by continuously integrating real-time data from sensors and IoT devices to monitor, simulate, and optimize the building's performance throughout its lifecycle. This dynamic interaction enables proactive maintenance and operational efficiency, making Digital Twins a valuable evolution in construction management.

Table of Comparison

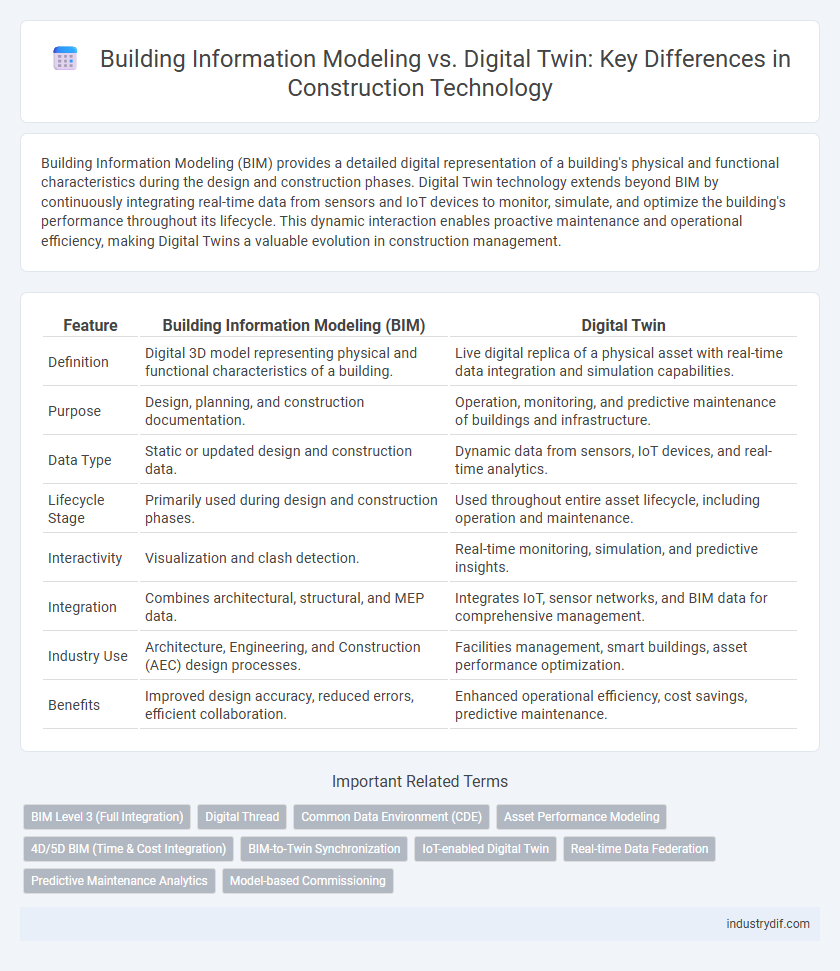

| Feature | Building Information Modeling (BIM) | Digital Twin |

|---|---|---|

| Definition | Digital 3D model representing physical and functional characteristics of a building. | Live digital replica of a physical asset with real-time data integration and simulation capabilities. |

| Purpose | Design, planning, and construction documentation. | Operation, monitoring, and predictive maintenance of buildings and infrastructure. |

| Data Type | Static or updated design and construction data. | Dynamic data from sensors, IoT devices, and real-time analytics. |

| Lifecycle Stage | Primarily used during design and construction phases. | Used throughout entire asset lifecycle, including operation and maintenance. |

| Interactivity | Visualization and clash detection. | Real-time monitoring, simulation, and predictive insights. |

| Integration | Combines architectural, structural, and MEP data. | Integrates IoT, sensor networks, and BIM data for comprehensive management. |

| Industry Use | Architecture, Engineering, and Construction (AEC) design processes. | Facilities management, smart buildings, asset performance optimization. |

| Benefits | Improved design accuracy, reduced errors, efficient collaboration. | Enhanced operational efficiency, cost savings, predictive maintenance. |

Understanding Building Information Modeling (BIM)

Building Information Modeling (BIM) is a digital representation of the physical and functional characteristics of a facility, providing a shared knowledge resource for information about a building throughout its lifecycle. BIM integrates multi-dimensional data, including 3D models, materials, and spatial relationships, enabling improved collaboration among architects, engineers, and contractors. This comprehensive approach enhances design accuracy, reduces errors, and optimizes project management compared to traditional construction methods.

Defining Digital Twin Technology

Digital Twin technology in construction involves creating a dynamic, real-time virtual replica of physical assets, incorporating data from sensors, BIM models, and IoT devices to simulate, monitor, and optimize building performance. Unlike Building Information Modeling (BIM), which provides a static, data-rich 3D representation during design and construction phases, Digital Twins extend beyond by integrating live operational data throughout the building lifecycle. This enables predictive maintenance, energy efficiency improvements, and informed decision-making, transforming asset management and facility operations.

Core Differences Between BIM and Digital Twin

Building Information Modeling (BIM) serves as a digital representation of a building's physical and functional characteristics during design and construction phases, primarily used for planning, visualization, and coordination. Digital Twin extends beyond BIM by integrating real-time sensor data and analytics to provide dynamic, continuously updated models that reflect the actual operating conditions of the asset throughout its lifecycle. The core difference lies in BIM's static nature for project execution versus the Digital Twin's dynamic, real-time monitoring and predictive capabilities for facility management and optimization.

Applications of BIM in Construction Projects

Building Information Modeling (BIM) enhances construction projects through detailed 3D modeling, clash detection, and project visualization, enabling precise planning and coordination among stakeholders. BIM's applications include cost estimation, scheduling, and resource management, which improve project efficiency and reduce delays. Integration with digital twins extends BIM's functionality by providing real-time monitoring and performance analysis for optimized facility management throughout the building lifecycle.

How Digital Twin Enhances Construction Management

Digital Twin technology enhances construction management by providing real-time, dynamic simulations of physical assets, enabling predictive maintenance and improved project monitoring. Unlike traditional Building Information Modeling (BIM), which offers static 3D models and planning data, Digital Twin integrates IoT sensors and live data feeds for continuous performance analysis. This leads to optimized resource allocation, accelerated decision-making, and reduced risk throughout the construction lifecycle.

Data Integration: BIM vs Digital Twin

Building Information Modeling (BIM) centralizes design and construction data during project planning, enabling detailed 3D models and documentation for collaboration. Digital Twins integrate real-time sensor data with BIM models, creating dynamic representations that monitor and optimize building performance throughout its lifecycle. While BIM focuses on static design data integration, Digital Twins emphasize continuous data assimilation for operational insights and predictive maintenance.

Real-Time Monitoring: The Digital Twin Advantage

Digital Twin technology offers superior real-time monitoring by integrating live data from sensors embedded in construction sites and buildings, enabling continuous performance analysis and immediate issue detection. Building Information Modeling (BIM) primarily provides static 3D models for design and collaboration but lacks dynamic real-time data capture and simulation capabilities. This real-time monitoring advantage of Digital Twins enhances proactive maintenance, optimizes asset management, and improves construction project outcomes through accurate, up-to-date digital replicas.

Lifecycle Management in BIM and Digital Twin

Building Information Modeling (BIM) provides a detailed 3D digital representation of a construction project's physical and functional characteristics, primarily used during design and construction phases for effective lifecycle management. Digital Twin technology extends beyond BIM by integrating real-time data from sensors and IoT devices, enabling continuous monitoring, predictive maintenance, and operational optimization throughout the asset's entire lifecycle. Lifecycle management with Digital Twins enhances asset performance and reduces operational costs by offering dynamic insights that evolve with the built environment.

Challenges in Adopting BIM and Digital Twin

Challenges in adopting Building Information Modeling (BIM) and Digital Twin technologies in construction include high initial costs, complex integration with existing systems, and the need for skilled professionals proficient in advanced software. Data interoperability issues and lack of standardized protocols hinder seamless collaboration among stakeholders, while concerns about data security and privacy present ongoing obstacles. Furthermore, resistance to change within organizations and the need for continuous updates and maintenance limit widespread implementation.

Future Trends: Bridging BIM and Digital Twin in Construction

Future trends in construction emphasize the integration of Building Information Modeling (BIM) and Digital Twin technologies to enhance project lifecycle management and operational efficiency. Advances in real-time data analytics, IoT sensors, and AI-driven simulations enable seamless synchronization between BIM's design phase and Digital Twin's real-world asset management. This convergence facilitates predictive maintenance, optimized resource allocation, and improved decision-making across construction and facility management sectors.

Related Important Terms

BIM Level 3 (Full Integration)

Building Information Modeling (BIM) Level 3 represents full integration with a shared, cloud-based platform that enables all stakeholders to collaborate on a unified 3D model, enhancing data consistency and project efficiency. Digital Twin extends BIM Level 3 by incorporating real-time sensor data and IoT connectivity for dynamic asset management, predictive maintenance, and operational simulation throughout the building lifecycle.

Digital Thread

Building Information Modeling (BIM) provides a detailed 3D representation of a construction project during its design and build phases, while Digital Twin extends this by offering a dynamic, real-time digital replica of the physical asset throughout its entire lifecycle. The Digital Thread connects BIM data, sensor inputs, and operational systems, enabling continuous feedback, predictive maintenance, and enhanced decision-making in facility management.

Common Data Environment (CDE)

Building Information Modeling (BIM) and Digital Twin technologies both rely heavily on a robust Common Data Environment (CDE) to centralize, manage, and share project information, enhancing collaboration and decision-making throughout the construction lifecycle. While BIM provides a detailed 3D model and data coordination during design and construction phases, Digital Twins extend this with real-time sensor data integration and operational analytics, maintaining an up-to-date virtual representation of the physical asset within the CDE.

Asset Performance Modeling

Building Information Modeling (BIM) provides detailed 3D representations and data management during the design and construction phases, while Digital Twin technology extends to real-time asset performance modeling by integrating sensor data and operational analytics throughout the building lifecycle. Asset performance modeling within Digital Twins enables predictive maintenance, energy efficiency optimization, and enhanced facility management, surpassing BIM's static data capabilities.

4D/5D BIM (Time & Cost Integration)

4D/5D Building Information Modeling (BIM) integrates time and cost data, enabling precise scheduling and budget forecasting throughout the construction lifecycle. Digital Twin technology extends this by creating a real-time, dynamic virtual replica of the physical asset, enhancing project management through continuous monitoring and predictive analytics.

BIM-to-Twin Synchronization

Building Information Modeling (BIM) provides the foundational 3D digital representations of physical and functional characteristics during the construction phase, while Digital Twin technology extends this by enabling real-time synchronization with operational data for accurate monitoring and predictive analytics. BIM-to-Twin synchronization ensures seamless integration of design updates, sensor data, and environmental conditions, optimizing asset management and lifecycle performance in smart building operations.

IoT-enabled Digital Twin

Building Information Modeling (BIM) serves as a static digital representation of a building's physical and functional characteristics, while IoT-enabled Digital Twin extends BIM by integrating real-time sensor data to monitor and optimize building performance dynamically. This convergence of BIM and IoT technologies facilitates predictive maintenance, energy efficiency, and enhanced decision-making throughout the building lifecycle.

Real-time Data Federation

Building Information Modeling (BIM) serves as a static 3D digital representation of a building's physical and functional characteristics, while Digital Twin integrates real-time data federation to continuously update the model with live sensor inputs, operational analytics, and environmental conditions. This dynamic synchronization enhances decision-making, predictive maintenance, and lifecycle management by providing an up-to-date, comprehensive view of the construction asset.

Predictive Maintenance Analytics

Building Information Modeling (BIM) provides detailed 3D representations and design data foundational for project planning, whereas Digital Twin technology integrates real-time sensor data and IoT analytics to enable accurate predictive maintenance analytics. Predictive maintenance leverages Digital Twin's continuous monitoring to forecast equipment failures and optimize building lifecycle management beyond BIM's static design models.

Model-based Commissioning

Building Information Modeling (BIM) serves as a comprehensive digital representation of a building's physical and functional characteristics during design and construction, while Digital Twin extends BIM by integrating real-time data for dynamic model-based commissioning throughout the building lifecycle. Model-based commissioning leverages Digital Twin's continuous data feedback to optimize system performance, enabling proactive maintenance and reducing operational costs compared to traditional BIM-based commissioning processes.

Building Information Modeling vs Digital Twin Infographic

industrydif.com

industrydif.com