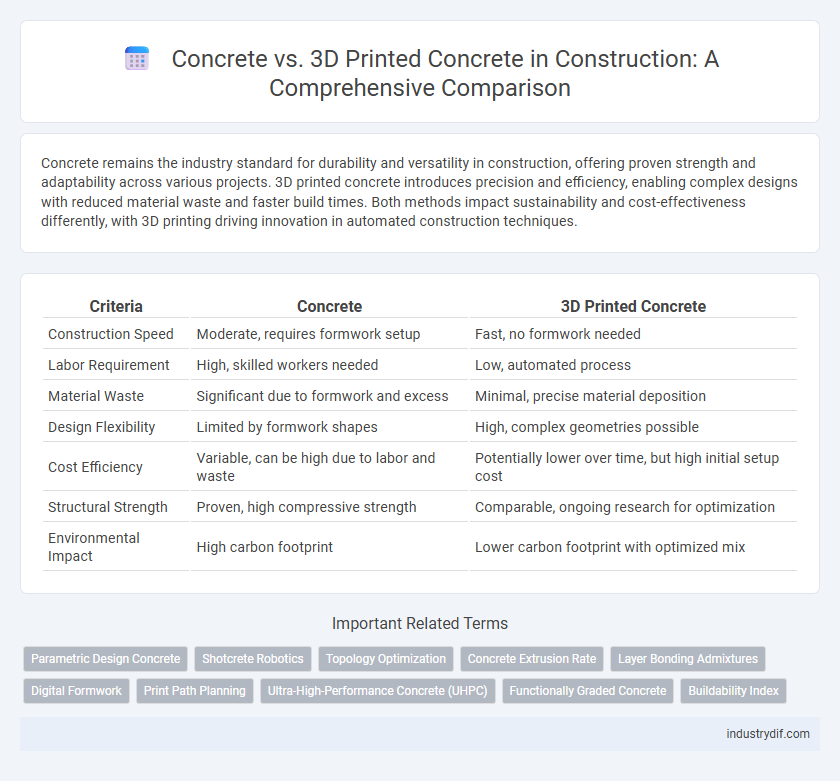

Concrete remains the industry standard for durability and versatility in construction, offering proven strength and adaptability across various projects. 3D printed concrete introduces precision and efficiency, enabling complex designs with reduced material waste and faster build times. Both methods impact sustainability and cost-effectiveness differently, with 3D printing driving innovation in automated construction techniques.

Table of Comparison

| Criteria | Concrete | 3D Printed Concrete |

|---|---|---|

| Construction Speed | Moderate, requires formwork setup | Fast, no formwork needed |

| Labor Requirement | High, skilled workers needed | Low, automated process |

| Material Waste | Significant due to formwork and excess | Minimal, precise material deposition |

| Design Flexibility | Limited by formwork shapes | High, complex geometries possible |

| Cost Efficiency | Variable, can be high due to labor and waste | Potentially lower over time, but high initial setup cost |

| Structural Strength | Proven, high compressive strength | Comparable, ongoing research for optimization |

| Environmental Impact | High carbon footprint | Lower carbon footprint with optimized mix |

Material Composition: Traditional vs 3D Printed Concrete

Traditional concrete consists of cement, water, sand, and coarse aggregates mixed to form a durable and strong material, while 3D printed concrete typically uses a specialized mixture with higher cement content, additives, and fine aggregates to optimize flowability and setting time. The material composition in 3D printed concrete is tailored for layer adhesion and rapid hardening to support complex geometries without formwork. Variations in admixtures and rheology modifiers in 3D printed concrete significantly enhance precision and structural integrity compared to conventional concrete mixes.

Strength and Durability Comparison

Concrete traditionally used in construction offers proven compressive strength typically ranging from 3,000 to 5,000 psi, ensuring robust durability in load-bearing applications. 3D printed concrete, enhanced with advanced admixtures and layer-by-layer deposition techniques, can achieve comparable or superior tensile strength and durability through optimized material placement and curing processes. The additive manufacturing approach reduces material waste and potential weak points, resulting in structures with enhanced resilience against environmental stressors and improved long-term performance.

Speed of Construction: Manual vs Automated Methods

Traditional concrete construction involves manual mixing, pouring, and curing processes that typically extend project timelines due to labor-intensive steps and curing periods. 3D printed concrete significantly accelerates construction speed by using automated layering techniques that reduce material waste and eliminate the need for formwork, enabling faster erection of complex structures. Automated 3D printing systems allow continuous, precise deposition of concrete, resulting in project completion times reduced by up to 50% compared to conventional methods.

Design Flexibility and Customization

Concrete offers reliable strength and durability but is limited in design flexibility due to traditional formwork constraints. 3D printed concrete enables complex geometries and intricate designs, allowing for unprecedented customization without the need for molds. This technology reduces material waste and accelerates the construction process while supporting innovative architectural expressions.

Cost Efficiency and Scalability

Traditional concrete remains cost-efficient for large-scale construction due to established supply chains and economies of scale, while 3D printed concrete offers significant savings by reducing labor and material waste. 3D printed concrete allows for rapid, customizable designs with minimal formwork, enhancing scalability for complex architectural projects. Despite higher initial technology investments, 3D printed concrete's precision and reduced construction time optimize cost efficiency in customized or smaller batch productions.

Environmental Impact and Sustainability

Traditional concrete production generates approximately 8% of global CO2 emissions due to cement manufacturing, contributing significantly to environmental degradation. In contrast, 3D printed concrete uses precise material application and advanced formulations to reduce waste and carbon footprint, enhancing sustainability in construction. The adoption of 3D printed concrete promotes energy efficiency and resource conservation while minimizing landfill impact from construction debris.

Labor Requirements and Skillsets

Traditional concrete construction demands extensive labor with specialized skills in mixing, pouring, and finishing, often requiring multiple tradespeople on-site. In contrast, 3D printed concrete significantly reduces labor intensity by automating the layering process, relying on technicians skilled in operating advanced robotic equipment and digital design software. This shift in skillsets emphasizes expertise in robotics, computer-aided design (CAD), and material science, transforming workforce dynamics in the construction industry.

Quality Control and Consistency

Traditional concrete benefits from well-established quality control protocols ensuring uniform mix ratios and curing processes, resulting in consistent structural integrity. 3D printed concrete leverages automated extrusion and precise layer-by-layer deposition, enhancing consistency by minimizing human error and material variability. Advanced sensors integrated within 3D printing systems provide real-time feedback, further improving quality control compared to conventional methods.

Applications in Modern Construction

Concrete remains a cornerstone material in traditional construction for foundations, walls, and infrastructure, prized for its durability and load-bearing capacity. 3D printed concrete, leveraging computer-controlled layering, enables the creation of complex architectural designs and customizable structures with reduced material waste and labor costs. Modern construction increasingly adopts 3D printed concrete for rapid prototyping, intricate facade elements, and sustainable building solutions.

Future Trends in Concrete Technology

3D printed concrete is revolutionizing the construction industry by enabling faster, more efficient building processes with reduced labor costs and material waste compared to traditional concrete methods. Innovations in printable concrete mixtures enhance durability and sustainability through the incorporation of recycled materials and advanced additives that improve strength and curing time. Future trends indicate that integrating automation, AI-driven design optimization, and eco-friendly materials will further transform concrete technology, promoting smart construction and reducing the environmental footprint.

Related Important Terms

Parametric Design Concrete

Parametric design in concrete construction allows for precise control over complex geometries and material efficiency, enabling the production of intricate forms that traditional concrete methods cannot achieve. 3D printed concrete leverages parametric design software to optimize structural performance and reduce waste, offering faster construction times and greater customization compared to conventional concrete casting techniques.

Shotcrete Robotics

Shotcrete robotics enhances traditional concrete application by automating the spraying process, improving precision and reducing labor costs in construction projects. Compared to conventional 3D printed concrete, shotcrete robotics enables faster layering with superior adhesion and minimal material waste, optimizing structural integrity and project efficiency.

Topology Optimization

Topology optimization in concrete construction enhances material distribution for strength and durability while minimizing waste, making traditional concrete designs less efficient compared to 3D printed concrete. 3D printed concrete enables intricate geometries and precise control over structural topology, optimizing load paths and reducing material use, leading to innovative, cost-effective, and sustainable building solutions.

Concrete Extrusion Rate

Concrete extrusion rate in traditional concrete pouring averages around 1 to 3 meters per hour, constrained by manual layer application and setting times, whereas 3D printed concrete can achieve extrusion rates exceeding 5 meters per hour due to automated, continuous deposition. Enhanced extrusion rates in 3D printed concrete enable faster construction cycles and improved material efficiency, significantly reducing labor costs and project timelines.

Layer Bonding Admixtures

Layer bonding admixtures in 3D printed concrete significantly enhance interlayer adhesion by improving the chemical and mechanical bonding between successive layers, reducing delamination and increasing structural integrity compared to traditional concrete. These admixtures optimize rheological properties, enabling better control of printability and setting time, which results in stronger, more durable constructs with minimized weak interfaces.

Digital Formwork

Digital formwork in 3D printed concrete allows precise, customizable molds that significantly reduce material waste and labor costs compared to traditional concrete casting. This innovative technology enhances structural complexity and build speed by eliminating the need for conventional formwork, offering increased design flexibility and sustainability in construction projects.

Print Path Planning

Print path planning in 3D printed concrete optimizes layer deposition, minimizing material waste and enhancing structural integrity through precise geometric control. Traditional concrete placement relies on manual formwork, limiting design complexity and increasing labor costs compared to the automated, customizable path execution of 3D printing technology.

Ultra-High-Performance Concrete (UHPC)

Ultra-High-Performance Concrete (UHPC) exhibits superior mechanical properties and durability compared to traditional concrete, offering compressive strengths exceeding 150 MPa and enhanced resistance to environmental degradation. When integrated with 3D printing technology, UHPC enables precise, complex architectural forms with reduced material waste and accelerated construction times, revolutionizing modern building methods.

Functionally Graded Concrete

Functionally graded concrete (FGC) enhances structural performance by varying material composition and properties along the volume, optimizing strength and durability where needed most. Compared to traditional concrete, 3D printed concrete enables precise control of FGC gradients layer-by-layer, reducing material waste and enabling complex, customized designs in construction projects.

Buildability Index

Concrete exhibits a traditional buildability index characterized by its well-understood setting time and compressive strength, allowing for consistent layering and formwork stability in construction. In contrast, 3D printed concrete demonstrates a higher buildability index due to its rapid setting properties and controlled extrusion rate, enabling complex geometries and reduced material waste while maintaining structural integrity.

Concrete vs 3D Printed Concrete Infographic

industrydif.com

industrydif.com