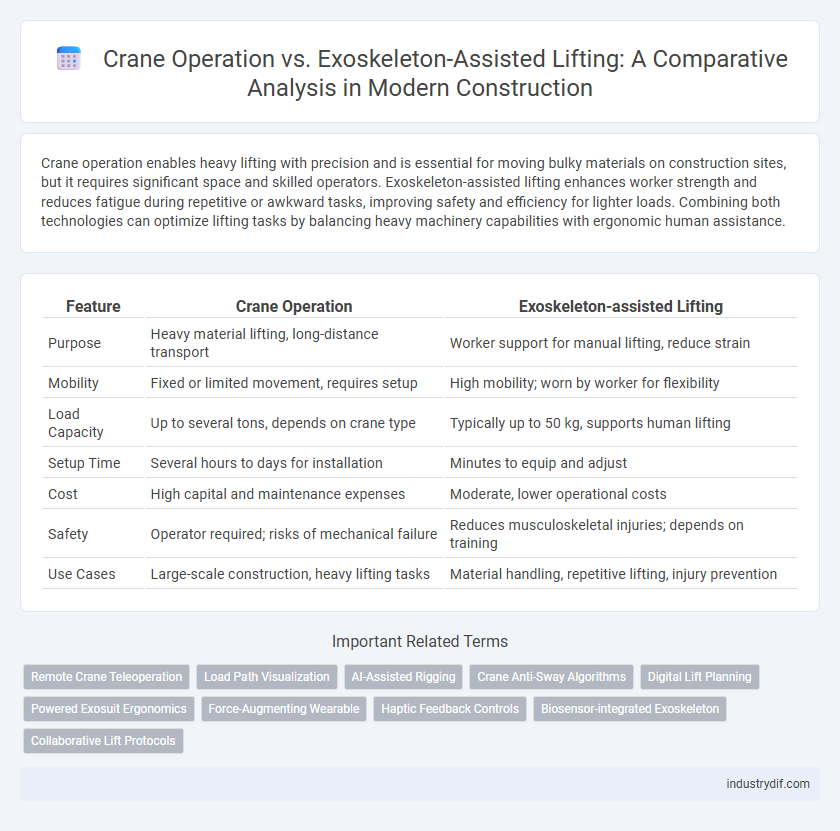

Crane operation enables heavy lifting with precision and is essential for moving bulky materials on construction sites, but it requires significant space and skilled operators. Exoskeleton-assisted lifting enhances worker strength and reduces fatigue during repetitive or awkward tasks, improving safety and efficiency for lighter loads. Combining both technologies can optimize lifting tasks by balancing heavy machinery capabilities with ergonomic human assistance.

Table of Comparison

| Feature | Crane Operation | Exoskeleton-assisted Lifting |

|---|---|---|

| Purpose | Heavy material lifting, long-distance transport | Worker support for manual lifting, reduce strain |

| Mobility | Fixed or limited movement, requires setup | High mobility; worn by worker for flexibility |

| Load Capacity | Up to several tons, depends on crane type | Typically up to 50 kg, supports human lifting |

| Setup Time | Several hours to days for installation | Minutes to equip and adjust |

| Cost | High capital and maintenance expenses | Moderate, lower operational costs |

| Safety | Operator required; risks of mechanical failure | Reduces musculoskeletal injuries; depends on training |

| Use Cases | Large-scale construction, heavy lifting tasks | Material handling, repetitive lifting, injury prevention |

Crane Operation: Key Functions in Modern Construction

Crane operation remains a cornerstone in modern construction, enabling the efficient lifting and precise placement of heavy materials such as steel beams and concrete panels. Its key functions include load handling, site mobility, and enhanced safety through advanced control systems like remote operation and load monitoring. These capabilities significantly expedite construction timelines while minimizing onsite risks compared to traditional manual lifting methods.

Exoskeleton-Assisted Lifting: Advancements and Applications

Exoskeleton-assisted lifting in construction enhances worker safety and productivity by reducing musculoskeletal strain during heavy material handling. Recent advancements include lightweight, ergonomic designs integrated with smart sensors that adapt to user movement and load conditions, optimizing support and injury prevention. Applications span steel erection, repetitive lifting tasks, and overhead work, significantly minimizing fatigue and injury risk compared to traditional crane operation in confined or complex environments.

Safety Standards: Crane Operation vs Exoskeleton Technology

Crane operation mandates strict adherence to OSHA and ANSI safety standards, including regular inspections, load capacity limits, and operator certification to prevent accidents and ensure site safety. Exoskeleton-assisted lifting integrates ergonomic support and reduces musculoskeletal injury risks, supported by emerging safety protocols from organizations like NIOSH that emphasize user training and device maintenance. Comparing both, cranes focus on mechanical load management and environmental hazard control, while exoskeletons enhance human biomechanics with real-time monitoring for fatigue and posture, forming a complementary approach to workplace safety.

Efficiency Comparison: Cranes and Wearable Exoskeletons

Crane operation provides high load capacity and reach, making it ideal for lifting heavy materials over long distances on construction sites, which enhances overall project efficiency by reducing manual labor demands. Wearable exoskeletons improve worker endurance and reduce fatigue by supporting human lifting efforts during repetitive or moderate-load tasks, enabling faster task completion and minimizing injury risks. Combining cranes for heavy, large-scale lifting with exoskeleton-assisted manual handling optimizes efficiency by leveraging mechanical strength and human mobility for diverse construction activities.

Workforce Training: Crane Operators and Exoskeleton Users

Crane operation requires extensive workforce training focused on mastering controls, safety protocols, and load management to ensure precision and prevent accidents. Exoskeleton-assisted lifting demands specialized training emphasizing ergonomic safety, proper device calibration, and real-time monitoring of user movement to reduce musculoskeletal strain. Both skill sets enhance construction efficiency but rely on distinct training methodologies tailored to equipment complexity and human-machine interaction.

Cost Analysis: Investment in Cranes vs Exoskeleton Systems

Investment in crane operation involves significant upfront costs, including purchase, installation, and maintenance of heavy machinery, often ranging from $150,000 to over $1 million per unit. Exoskeleton-assisted lifting systems present a lower initial investment, with prices typically between $5,000 and $15,000 per suit, reducing long-term operational expenses by minimizing worker fatigue and injury-related costs. Cost analysis reveals cranes demand higher capital expenditure but offer greater load capacity, while exoskeletons optimize labor efficiency and safety at a fraction of the cost, making them complementary solutions in construction environments.

Load Capacity: Exoskeletons Versus Industrial Cranes

Industrial cranes typically offer load capacities ranging from several tons to hundreds of tons, enabling the handling of extremely heavy materials on construction sites. Exoskeleton-assisted lifting systems, while enhancing human strength and endurance, generally support loads up to 50 kilograms, focusing on reducing worker strain rather than replacing heavy machinery. The significant disparity in load capacity highlights cranes as essential for large-scale lifting tasks, whereas exoskeletons complement manual labor by improving safety and efficiency in moderate load handling.

Site Flexibility: Mobility of Cranes and Exoskeleton Devices

Cranes provide high lifting capacity and extended reach but are limited by their fixed setup and crane site requirements, reducing flexibility on congested or uneven terrain. Exoskeleton-assisted lifting enhances worker mobility and allows for dynamic movement across complex site layouts without the need for repositioning heavy machinery. This mobility advantage enables more efficient task execution in confined spaces where crane access is restricted.

Ergonomics and Worker Health: Traditional vs Exoskeleton Lifting

Crane operation in construction relies on mechanical lifting, reducing direct physical strain but increasing risks related to load control and operator ergonomics. Exoskeleton-assisted lifting enhances worker health by supporting posture and reducing musculoskeletal stress during manual handling tasks, promoting better ergonomics on-site. Comparing the two, exoskeletons offer improved physical well-being for laborers, while cranes provide efficiency for heavy loads at a distance.

Future Trends: Integrating Cranes with Exoskeleton Technology

Future trends in construction emphasize the integration of crane operation with exoskeleton-assisted lifting to enhance worker safety and increase efficiency on job sites. Combining advanced sensor technology in cranes with wearable exoskeleton systems enables real-time load management and reduces physical strain on operators. This convergence of automation and wearable robotics is projected to revolutionize heavy lifting, enabling more precise control and minimizing workplace injuries in complex construction environments.

Related Important Terms

Remote Crane Teleoperation

Remote crane teleoperation enhances construction site safety by allowing operators to control cranes from secure locations, reducing exposure to hazardous environments. Integrating exoskeleton-assisted lifting with remote teleoperation can optimize worker ergonomics and increase precision in heavy load handling.

Load Path Visualization

Crane operation utilizes advanced load path visualization software to precisely monitor stress distribution and ensure safe lifting trajectories, enhancing operator control and reducing structural risks. Exoskeleton-assisted lifting integrates real-time biomechanical feedback and augmented reality displays, enabling workers to visualize load paths directly on their bodies for optimized posture and injury prevention.

AI-Assisted Rigging

AI-assisted rigging enhances crane operation by integrating machine learning algorithms that optimize load positioning and improve safety during lifts. Exoskeleton-assisted lifting complements this technology by reducing operator fatigue and increasing precision, ultimately streamlining construction workflows.

Crane Anti-Sway Algorithms

Crane anti-sway algorithms utilize sensor data and predictive modeling to minimize load oscillations, enhancing precision and safety in crane operation on construction sites. Compared to exoskeleton-assisted lifting, these algorithms significantly increase load control efficiency, reducing the risk of accidents and improving project timelines.

Digital Lift Planning

Digital lift planning enhances crane operation safety and efficiency by integrating real-time data, risk assessments, and load characteristics, reducing errors and downtime. Exoskeleton-assisted lifting complements this by improving worker ergonomics and strength, but digital tools in crane operation remain crucial for precise lift path simulation and resource coordination.

Powered Exosuit Ergonomics

Powered exosuit ergonomics enhance crane operation by reducing operator fatigue and minimizing musculoskeletal strain during heavy lifting tasks. Integrating exoskeleton-assisted lifting with traditional crane use improves safety and efficiency by distributing load stress and supporting natural body movements.

Force-Augmenting Wearable

Force-augmenting wearable exoskeletons enhance crane operation by reducing musculoskeletal strain and increasing lifting endurance for construction workers, enabling safer and more efficient manual load handling. Unlike traditional crane operation that relies solely on mechanical lifting, exoskeleton-assisted lifting integrates human biomechanics with powered support, improving precision and minimizing fatigue during repetitive or heavy-duty tasks.

Haptic Feedback Controls

Crane operation relies heavily on haptic feedback controls to provide operators with precise tactile sensations that enhance maneuverability and load stability, reducing the risk of accidents in complex construction environments. Exoskeleton-assisted lifting integrates advanced haptic feedback systems to improve wearer posture and force distribution, significantly decreasing operator fatigue while increasing lift accuracy and safety on-site.

Biosensor-integrated Exoskeleton

Biosensor-integrated exoskeletons enhance crane operation by providing real-time feedback on worker posture and muscle strain, reducing the risk of injury and increasing lifting precision. These smart wearables optimize manual lifting tasks by adapting assistance levels based on biosensor data, improving efficiency and safety on construction sites.

Collaborative Lift Protocols

Collaborative lift protocols in construction prioritize synchronized coordination between crane operation and exoskeleton-assisted lifting to enhance safety and efficiency during heavy material handling. Integrating real-time communication systems and standardized load-sharing procedures reduces the risk of accidents and optimizes load distribution across mechanical and human-assisted support.

Crane Operation vs Exoskeleton-assisted Lifting Infographic

industrydif.com

industrydif.com