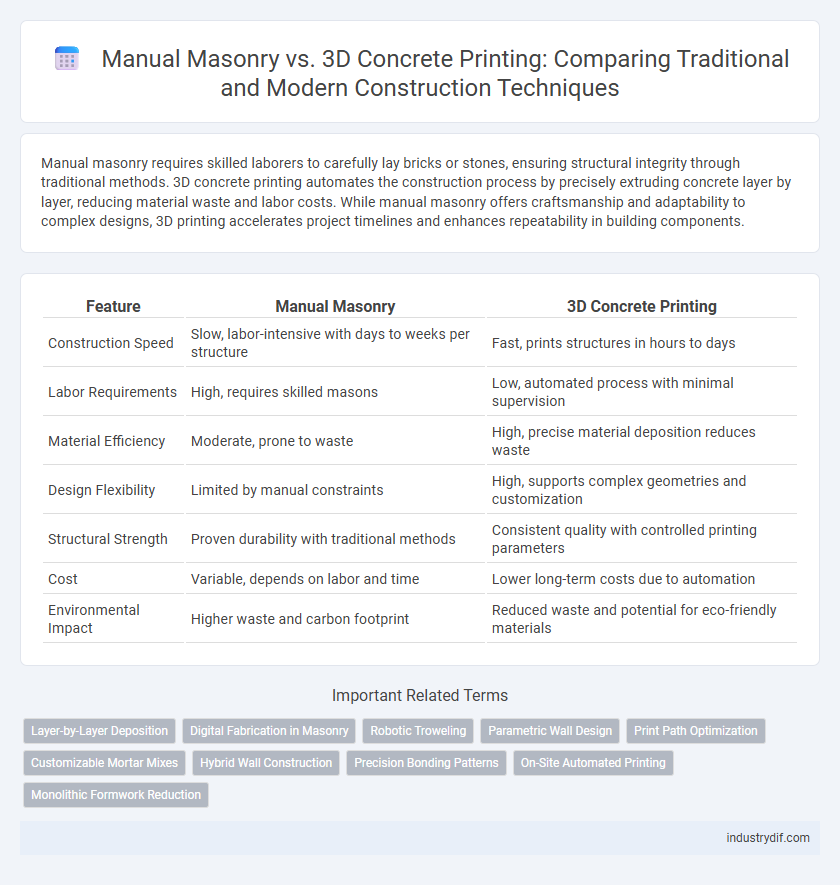

Manual masonry requires skilled laborers to carefully lay bricks or stones, ensuring structural integrity through traditional methods. 3D concrete printing automates the construction process by precisely extruding concrete layer by layer, reducing material waste and labor costs. While manual masonry offers craftsmanship and adaptability to complex designs, 3D printing accelerates project timelines and enhances repeatability in building components.

Table of Comparison

| Feature | Manual Masonry | 3D Concrete Printing |

|---|---|---|

| Construction Speed | Slow, labor-intensive with days to weeks per structure | Fast, prints structures in hours to days |

| Labor Requirements | High, requires skilled masons | Low, automated process with minimal supervision |

| Material Efficiency | Moderate, prone to waste | High, precise material deposition reduces waste |

| Design Flexibility | Limited by manual constraints | High, supports complex geometries and customization |

| Structural Strength | Proven durability with traditional methods | Consistent quality with controlled printing parameters |

| Cost | Variable, depends on labor and time | Lower long-term costs due to automation |

| Environmental Impact | Higher waste and carbon footprint | Reduced waste and potential for eco-friendly materials |

Introduction to Manual Masonry and 3D Concrete Printing

Manual masonry involves skilled laborers shaping and assembling bricks, stones, or blocks to construct walls and structures, relying heavily on craftsmanship and traditional techniques. In contrast, 3D concrete printing utilizes automated, computer-controlled machines to layer concrete precisely, enabling faster construction with reduced material waste and labor costs. Both methods serve critical roles in construction, with manual masonry offering artisanal quality and 3D printing providing efficiency and innovative design possibilities.

Historical Evolution of Construction Techniques

Manual masonry has been a cornerstone of construction for millennia, relying on skilled craftsmen to shape and assemble materials like stone and brick with precision. The historical evolution of construction techniques witnessed a shift with the emergence of 3D concrete printing, which automates the layering process, reducing labor and material waste while enabling complex architectural designs. This transition marks a significant innovation in construction technology, blending traditional craftsmanship knowledge with advanced digital fabrication methods.

Materials Used in Manual Masonry vs 3D Printing

Manual masonry predominantly utilizes traditional materials such as bricks, concrete blocks, and mortar, which comprise cement, sand, and water, providing proven structural strength and durability. In contrast, 3D concrete printing employs specially formulated, pumpable concrete mixtures with additives that enhance flowability, setting time, and bonding capability, optimized for layer-by-layer extrusion. These material innovations in 3D printing enable faster construction with reduced waste while maintaining structural integrity comparable to conventional masonry.

Comparative Construction Processes

Manual masonry relies on skilled labor to lay bricks or stones sequentially, requiring time-intensive precision and physical effort, while 3D concrete printing automates layer-by-layer deposition using specialized printers to rapidly build complex structures with minimal human intervention. The traditional masonry process involves mortar mixing, brick alignment, and curing phases, whereas 3D printing utilizes computer-aided design (CAD) models to extrude customizable concrete mixtures directly onto the construction site, reducing material waste. Efficiency gains from 3D printing result in faster build times and consistent quality control compared to the variability and slower pace inherent in manual masonry techniques.

Structural Integrity and Durability

Manual masonry offers proven structural integrity through time-tested techniques, providing durable and resilient building foundations with strong bonding between bricks or stones. 3D concrete printing enhances precision and uniformity, reducing human error and creating optimized load-bearing structures with high material consistency. Both methods contribute to long-term durability, but 3D printing enables complex geometries that improve stress distribution, while manual masonry relies on skilled craftsmanship for enhanced robustness.

Cost Efficiency and Budget Considerations

Manual masonry involves higher labor costs and extended project timelines, increasing overall expenses significantly compared to 3D concrete printing. 3D concrete printing reduces material waste and labor needs, providing substantial budget savings and faster construction cycles. The initial investment in 3D printing technology is offset by long-term cost efficiency and enhanced project scalability.

Labor Requirements and Workforce Skills

Manual masonry demands highly skilled laborers with expertise in bricklaying, stone cutting, and mortar application, often requiring extensive training and hands-on experience. 3D concrete printing reduces the need for specialized manual labor, instead relying on technicians proficient in operating and maintaining automated machinery and digital design software. This shift significantly lowers workforce size but increases the demand for tech-savvy professionals capable of managing advanced construction technology.

Project Turnaround Time and Scheduling

Manual masonry often requires longer project turnaround times due to labor-intensive processes and dependency on skilled craftsmen, leading to potential scheduling delays. In contrast, 3D concrete printing significantly accelerates construction by automating layering, reducing material waste, and enabling continuous operation, which enhances adherence to tight project schedules. Project managers leveraging 3D printing technology benefit from predictable timelines and faster completion rates, optimizing overall workflow efficiency.

Sustainability and Environmental Impact

Manual masonry relies heavily on traditional materials like fired bricks and cement, which often involve high carbon emissions due to energy-intensive manufacturing processes and resource extraction. In contrast, 3D concrete printing utilizes precise material placement, reducing waste by up to 60% and enabling the use of eco-friendly or recycled concrete mixes that lower the overall carbon footprint. This technology also minimizes site disruption and energy consumption during construction, making it a more sustainable solution compared to conventional masonry methods.

Future Trends in Construction Technology

3D concrete printing is revolutionizing the construction industry by enabling faster project completion and reducing material waste compared to manual masonry. Advances in robotics, AI integration, and sustainable materials are driving the scalability of 3D printing for complex architectural designs and affordable housing solutions. Future trends indicate a shift towards hybrid techniques that combine the precision of automated printing with the craftsmanship of traditional masonry for enhanced structural integrity and aesthetic appeal.

Related Important Terms

Layer-by-Layer Deposition

Manual masonry relies on skilled labor to apply mortar and place bricks or blocks layer-by-layer, ensuring structural integrity through precise alignment and craftsmanship. In contrast, 3D concrete printing automates the layer-by-layer deposition process using computer-controlled nozzles, enabling faster construction with reduced material waste and enhanced design flexibility.

Digital Fabrication in Masonry

Digital fabrication in masonry through 3D concrete printing significantly enhances precision, reduces material waste, and accelerates construction timelines compared to traditional manual masonry techniques. This technology enables complex architectural designs with consistent quality, optimizing resource efficiency and labor costs in modern construction projects.

Robotic Troweling

Robotic troweling in 3D concrete printing ensures consistent surface quality and accelerates project timelines by automating the finishing process, minimizing human error compared to traditional manual masonry. This technology enhances precision in layer smoothing and curing control, resulting in structurally sound and aesthetically superior concrete surfaces.

Parametric Wall Design

Parametric wall design in 3D concrete printing enables precise customization of complex geometries and optimized material usage, surpassing the limitations of manual masonry in speed and structural efficiency. This technology allows for the integration of advanced architectural features and functional elements within walls, significantly reducing labor costs and construction waste.

Print Path Optimization

Manual masonry relies on skilled labor to shape and place each brick, often leading to variability in build precision and slower progress. Print path optimization in 3D concrete printing enhances efficiency by strategically planning nozzle movements, reducing material waste, and enabling faster, more accurate construction of complex structures.

Customizable Mortar Mixes

Manual masonry allows precise control over mortar mix customization, enabling adjustments in water-cement ratios and additives to suit specific project requirements. In contrast, 3D concrete printing utilizes programmable mix formulations optimized for flowability and setting time, enhancing consistency but limiting real-time on-site modifications.

Hybrid Wall Construction

Hybrid wall construction combines manual masonry's craftsmanship with 3D concrete printing's precision to optimize structural integrity and reduce labor costs. Utilizing printed concrete layers for core support and hand-laid masonry for finishes enhances durability, speed, and customization in modern building projects.

Precision Bonding Patterns

Manual masonry relies on skilled labor to create precision bonding patterns, but human error often leads to inconsistencies in alignment and mortar distribution. In contrast, 3D concrete printing utilizes computer-controlled extrusion, ensuring exact replication of complex bonding patterns with superior accuracy and uniformity.

On-Site Automated Printing

On-site automated 3D concrete printing significantly reduces labor costs and construction time by precisely depositing layers directly at the build location, eliminating the need for extensive formwork and scaffolding associated with manual masonry. This technology enhances structural accuracy and design flexibility, enabling complex geometries and integrated utilities that manual masonry cannot efficiently achieve.

Monolithic Formwork Reduction

Manual masonry involves assembling bricks or blocks individually, resulting in time-intensive processes and significant formwork usage, while 3D concrete printing significantly reduces monolithic formwork by extruding concrete in precise layers directly on-site. This technology minimizes material waste and labor costs, enhancing construction speed and structural efficiency in complex designs.

Manual Masonry vs 3D Concrete Printing Infographic

industrydif.com

industrydif.com