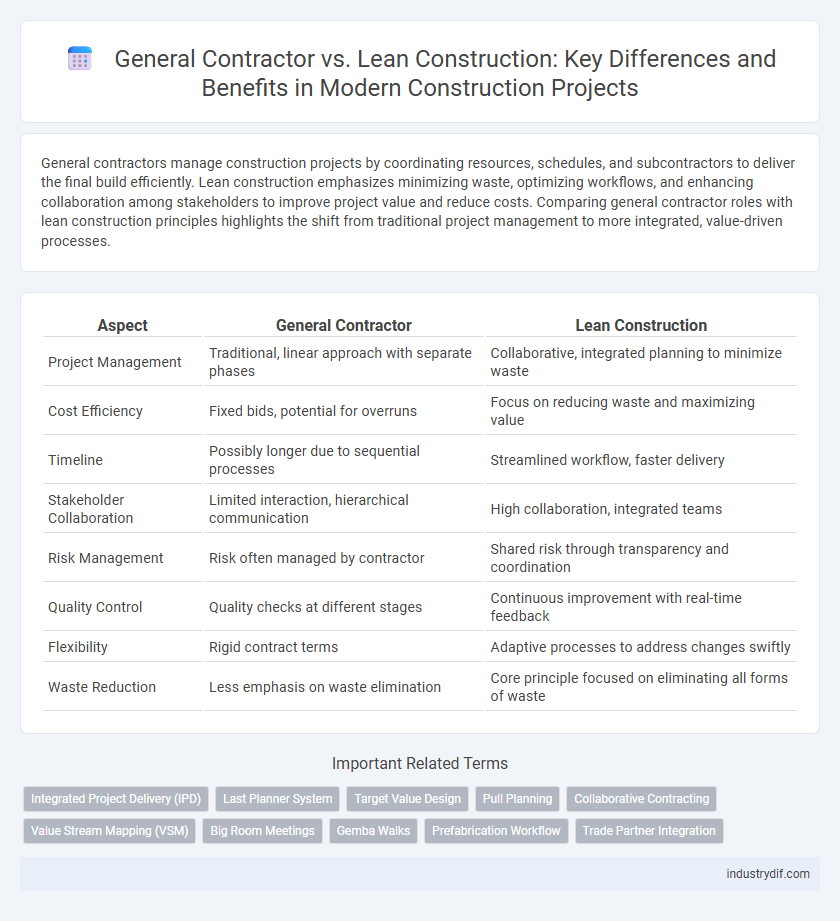

General contractors manage construction projects by coordinating resources, schedules, and subcontractors to deliver the final build efficiently. Lean construction emphasizes minimizing waste, optimizing workflows, and enhancing collaboration among stakeholders to improve project value and reduce costs. Comparing general contractor roles with lean construction principles highlights the shift from traditional project management to more integrated, value-driven processes.

Table of Comparison

| Aspect | General Contractor | Lean Construction |

|---|---|---|

| Project Management | Traditional, linear approach with separate phases | Collaborative, integrated planning to minimize waste |

| Cost Efficiency | Fixed bids, potential for overruns | Focus on reducing waste and maximizing value |

| Timeline | Possibly longer due to sequential processes | Streamlined workflow, faster delivery |

| Stakeholder Collaboration | Limited interaction, hierarchical communication | High collaboration, integrated teams |

| Risk Management | Risk often managed by contractor | Shared risk through transparency and coordination |

| Quality Control | Quality checks at different stages | Continuous improvement with real-time feedback |

| Flexibility | Rigid contract terms | Adaptive processes to address changes swiftly |

| Waste Reduction | Less emphasis on waste elimination | Core principle focused on eliminating all forms of waste |

Introduction to Construction Project Delivery Methods

General contractors traditionally manage construction projects by coordinating labor, materials, and subcontractors under a single contract, ensuring project completion within scope, time, and budget. Lean construction emphasizes maximizing value and minimizing waste through collaborative processes, continuous improvement, and just-in-time delivery. Understanding these construction project delivery methods helps stakeholders select strategies that optimize efficiency, cost control, and overall project success.

Defining the Role of a General Contractor

A General Contractor manages the overall construction project, coordinating subcontractors, scheduling, budgeting, and ensuring compliance with safety and building codes. In contrast, Lean Construction emphasizes maximizing value by minimizing waste, fostering collaboration, and continuously improving processes throughout the project lifecycle. Defining the role of a General Contractor within Lean Construction requires integrating traditional project management with lean principles to enhance efficiency and deliver higher quality outcomes.

Key Principles of Lean Construction

Lean Construction emphasizes eliminating waste, optimizing workflows, and enhancing value for clients through continuous improvement and collaboration. Key principles include just-in-time delivery, pull scheduling, integrated project delivery, and respect for people, promoting efficiency and reducing costs. Unlike traditional general contractors focused on task completion, Lean Construction fosters transparency, communication, and stakeholder involvement throughout the project lifecycle.

Project Management Approaches: Traditional vs Lean

General contractors typically follow traditional project management approaches emphasizing sequential workflows, fixed scopes, and hierarchal decision-making structures. Lean construction focuses on collaborative processes, continuous improvement, and minimizing waste through integrated project delivery and pull planning techniques. Adopting lean principles enhances efficiency, reduces costs, and improves communication across project stakeholders compared to conventional methods used by general contractors.

Cost Control: General Contractor Method vs Lean Construction

Cost control in the General Contractor method often relies on fixed bids and change orders, which can lead to budget overruns due to unforeseen conditions. Lean Construction emphasizes continuous collaboration and waste reduction through techniques like Last Planner System, resulting in more accurate cost forecasting and minimized variability. Projects using Lean Construction typically achieve higher cost efficiency by integrating real-time data and aligning subcontractor incentives with overall project goals.

Scheduling and Timeline Optimization

General contractors traditionally manage construction projects through fixed schedules and linear timelines, often resulting in delays due to resource conflicts and scope changes. Lean Construction emphasizes continuous workflow, reducing waste by optimizing scheduling with techniques like critical chain project management and just-in-time delivery. This approach enhances timeline predictability, improves resource allocation, and accelerates project completion.

Risk Management Strategies in Construction

General contractors typically employ traditional risk management strategies focusing on contract clauses, insurance, and compliance to mitigate project risks. Lean construction, however, integrates collaborative risk management through continuous communication, waste reduction, and just-in-time delivery to minimize uncertainties. Emphasizing early stakeholder involvement and real-time problem-solving, lean construction enhances proactive risk control compared to the reactive approaches of general contractors.

Subcontractor Coordination and Collaboration

General contractors traditionally manage subcontractor coordination through hierarchical structures, often leading to communication delays and inefficiencies. Lean construction emphasizes collaborative workflows and integrated project delivery, fostering real-time information sharing and proactive problem-solving among subcontractors. This approach reduces waste, enhances schedule adherence, and improves overall project outcomes through seamless subcontractor collaboration.

Quality Assurance and Continuous Improvement

General contractors integrate quality assurance protocols to ensure project compliance with industry standards, relying on traditional methods that emphasize inspection and correction. Lean construction, however, embeds quality assurance within continuous improvement processes, using real-time data and collaborative workflows to prevent defects and enhance efficiency. This approach reduces rework costs and accelerates project timelines by fostering proactive problem-solving and waste elimination.

Choosing the Right Construction Approach for Your Project

Selecting the right construction approach depends on project goals, timelines, and budget constraints; general contractors offer comprehensive management and traditional project delivery, ensuring accountability and clear contracts. Lean Construction emphasizes minimizing waste and maximizing efficiency through collaborative planning and continuous improvement, ideal for complex projects requiring flexibility and innovation. Evaluating the scale, complexity, and stakeholder engagement level helps determine whether a general contractor or lean construction methodology best aligns with your project's success criteria.

Related Important Terms

Integrated Project Delivery (IPD)

Integrated Project Delivery (IPD) enhances collaboration among general contractors, architects, and owners, streamlining workflows and reducing risks through shared responsibilities and transparent communication. Lean Construction principles embedded within IPD minimize waste and maximize value by promoting early stakeholder involvement and continuous process improvement.

Last Planner System

General contractors traditionally manage construction projects through hierarchical scheduling, while Lean Construction employs the Last Planner System to enhance workflow reliability by fostering collaboration and real-time planning among all stakeholders. The Last Planner System reduces delays and waste by ensuring tasks are planned based on actual capacity and commitment, improving project delivery timelines and cost efficiency.

Target Value Design

General contractors traditionally manage project schedules and budgets, while Lean Construction emphasizes Target Value Design (TVD) to optimize costs and performance through collaborative planning and continuous value improvement. TVD aligns project goals with client budgets by integrating design, construction, and operational inputs, reducing waste and enhancing efficiency throughout the construction process.

Pull Planning

Pull planning in lean construction enhances project efficiency by aligning tasks with subcontractor availability and workflow, reducing delays and waste compared to traditional general contractor scheduling. This method fosters collaboration and just-in-time task execution, optimizing resource use and accelerating project delivery timelines.

Collaborative Contracting

Collaborative contracting in lean construction enhances project efficiency by fostering transparent communication and shared risk between general contractors and stakeholders, reducing waste and improving workflow. Unlike traditional general contracting, this approach aligns all parties towards common goals through integrated teams and value-based partnerships.

Value Stream Mapping (VSM)

General contractors traditionally manage construction projects through sequential phases, often encountering inefficiencies that Value Stream Mapping (VSM) in Lean Construction aims to eliminate by visualizing and optimizing workflow from design to delivery. Lean Construction leverages VSM to identify waste, reduce project lead times, and enhance collaboration, resulting in improved value and reduced costs compared to conventional general contracting methods.

Big Room Meetings

Big Room Meetings in Lean Construction enhance collaboration by co-locating general contractors, subcontractors, and stakeholders to streamline decision-making and reduce project delays. Unlike traditional general contractor approaches, this method fosters transparency, early conflict resolution, and continuous improvement for optimized project delivery.

Gemba Walks

General contractors enhance project efficiency by implementing Gemba Walks, directly observing on-site processes to identify bottlenecks and improve communication among teams. Lean Construction leverages Gemba Walks to promote continuous improvement, reduce waste, and optimize workflow by engaging frontline workers in real-time problem-solving.

Prefabrication Workflow

General contractors traditionally manage on-site construction tasks, while lean construction emphasizes a prefabrication workflow that streamlines processes, reduces waste, and accelerates project timelines. Implementing prefabricated components off-site enables lean construction to enhance quality control and minimize on-site labor, optimizing overall project efficiency.

Trade Partner Integration

Trade partner integration in lean construction enhances collaboration and minimizes waste by involving subcontractors early in the design and planning process, contrasting with the traditional general contractor model that often operates in a segmented, sequential manner. This integration improves project efficiency, reduces delays, and fosters continuous improvement through transparent communication and shared responsibilities.

General Contractor vs Lean Construction Infographic

industrydif.com

industrydif.com