Manual quantity takeoff relies on labor-intensive processes prone to human error, leading to time-consuming adjustments and potential cost overruns. 5D quantity takeoff integrates 3D modeling and time scheduling, enabling accurate material estimation alongside project timelines for enhanced efficiency. This digital approach streamlines resource allocation, reduces risks, and improves overall construction project management.

Table of Comparison

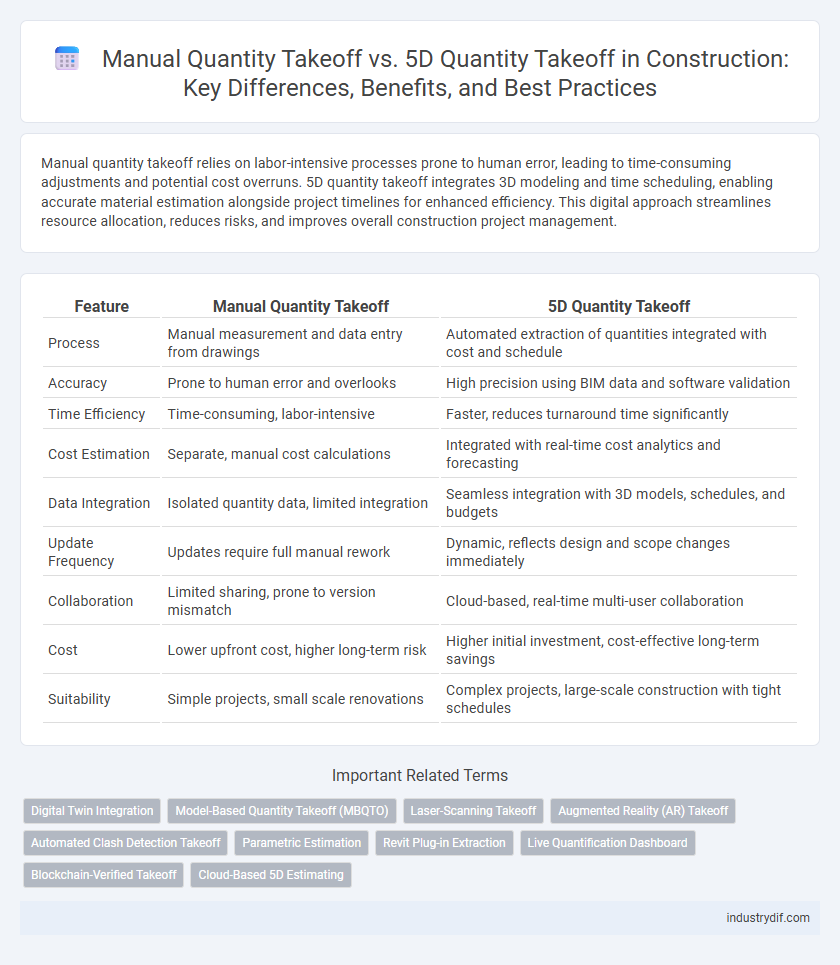

| Feature | Manual Quantity Takeoff | 5D Quantity Takeoff |

|---|---|---|

| Process | Manual measurement and data entry from drawings | Automated extraction of quantities integrated with cost and schedule |

| Accuracy | Prone to human error and overlooks | High precision using BIM data and software validation |

| Time Efficiency | Time-consuming, labor-intensive | Faster, reduces turnaround time significantly |

| Cost Estimation | Separate, manual cost calculations | Integrated with real-time cost analytics and forecasting |

| Data Integration | Isolated quantity data, limited integration | Seamless integration with 3D models, schedules, and budgets |

| Update Frequency | Updates require full manual rework | Dynamic, reflects design and scope changes immediately |

| Collaboration | Limited sharing, prone to version mismatch | Cloud-based, real-time multi-user collaboration |

| Cost | Lower upfront cost, higher long-term risk | Higher initial investment, cost-effective long-term savings |

| Suitability | Simple projects, small scale renovations | Complex projects, large-scale construction with tight schedules |

Introduction to Quantity Takeoff in Construction

Quantity takeoff in construction involves measuring and listing materials required for a project to ensure accurate cost estimation and resource planning. Manual quantity takeoff relies on traditional methods using blueprints and spreadsheets, which can be time-consuming and prone to human error. In contrast, 5D quantity takeoff integrates digital models and project timelines, enabling precise measurement and real-time cost analysis for enhanced project management.

Defining Manual Quantity Takeoff

Manual quantity takeoff involves physically measuring and recording material quantities from blueprints or drawings, often using spreadsheets or paper forms. This traditional method relies heavily on the estimator's accuracy and experience, making it time-consuming and prone to human error. Despite these challenges, manual quantity takeoff remains widely used in small-scale projects or where digital resources are limited.

Understanding 5D Quantity Takeoff

5D Quantity Takeoff integrates time and cost data with 3D models, enhancing accuracy and efficiency in construction project planning. Unlike Manual Quantity Takeoff, which relies on traditional measuring techniques and is prone to human error, 5D Quantity Takeoff automates material and labor estimations through Building Information Modeling (BIM) technology. This method enables real-time updates and more precise forecasting of project timelines and budgets, reducing risks and improving resource allocation.

Key Differences Between Manual and 5D Takeoff

Manual quantity takeoff relies on physical blueprints and manual calculations, increasing the risk of human error and consuming more time. 5D quantity takeoff integrates 3D modeling with project scheduling and cost estimation, providing real-time updates and enhanced accuracy. This digital approach improves collaboration, reduces rework, and accelerates decision-making in construction project management.

Accuracy and Error Rates: Manual vs 5D

Manual quantity takeoff often struggles with accuracy due to human error and time-consuming processes, leading to higher error rates and potential cost overruns. In contrast, 5D quantity takeoff integrates BIM technology to provide real-time material quantities with enhanced precision, significantly reducing discrepancies and miscalculations. This digital approach improves accuracy by automating measurements and linking quantities directly to project cost and schedule data, minimizing manual intervention and errors.

Time Efficiency and Labor Requirements

Manual quantity takeoff demands extensive labor hours and is prone to human error, significantly slowing project timelines. In contrast, 5D quantity takeoff leverages integrated BIM technology to automate measurements and cost estimations, drastically reducing time requirements. This digital approach minimizes labor input, enhances accuracy, and accelerates decision-making in construction project management.

Cost Implications of Each Method

Manual Quantity Takeoff often leads to higher labor costs and increased potential for human errors, resulting in budget overruns due to inaccurate material estimates. In contrast, 5D Quantity Takeoff integrates cost data with 3D models, enabling precise forecasting and real-time budget adjustments, significantly reducing contingency expenses. Construction projects utilizing 5D technology experience improved cost control, minimizing unexpected expenditures and optimizing resource allocation.

Integration with BIM and Project Management

Manual quantity takeoff relies on traditional methods such as paper blueprints and spreadsheets, often leading to increased errors and time consumption. In contrast, 5D quantity takeoff integrates seamlessly with Building Information Modeling (BIM), enabling real-time cost estimation and visualization linked directly to project schedules. This integration enhances project management by providing accurate, up-to-date data, facilitating better resource allocation and risk mitigation throughout the construction lifecycle.

Impact on Project Collaboration and Communication

Manual quantity takeoff often leads to fragmented data and communication gaps due to reliance on individual inputs and static documents, which hinders real-time collaboration among project stakeholders. In contrast, 5D quantity takeoff integrates cost, schedule, and quantity data into a centralized BIM platform, enabling synchronized updates and enhanced transparency that fosters effective teamwork. This collaborative environment reduces errors, accelerates decision-making, and improves overall project coordination.

Industry Trends: The Shift Toward 5D Quantity Takeoff

The construction industry increasingly adopts 5D quantity takeoff, integrating cost and scheduling data with 3D models to enhance accuracy and efficiency in project planning. This shift aligns with trends toward digital transformation and Building Information Modeling (BIM), enabling real-time updates and improved collaboration among stakeholders. Manual quantity takeoff remains in use for smaller projects but is gradually being replaced due to its susceptibility to errors and time-consuming nature.

Related Important Terms

Digital Twin Integration

Manual quantity takeoff relies on traditional blueprints and spreadsheets, leading to inefficiencies and higher risk of human error, whereas 5D quantity takeoff integrates with digital twin technology to provide real-time, accurate visualization of project quantities linked to time and cost data. Digital twin integration enhances project management by enabling dynamic updates and scenario analysis, improving resource allocation, cost forecasting, and overall construction efficiency.

Model-Based Quantity Takeoff (MBQTO)

Model-Based Quantity Takeoff (MBQTO) leverages Building Information Modeling (BIM) to automate and enhance accuracy in material quantity extraction, significantly reducing human error compared to traditional manual quantity takeoff methods. Integrating 5D data, MBQTO links quantities with cost and schedule information, optimizing project planning and resource allocation in construction management.

Laser-Scanning Takeoff

Manual quantity takeoff relies on traditional measurement techniques that are time-consuming and prone to human error, whereas 5D quantity takeoff integrates laser-scanning technology to capture precise, real-time dimensions and project data, enhancing accuracy and efficiency. Laser-scanning takeoff generates detailed 3D models that streamline the estimation process by automatically extracting quantities and linking them with cost and schedule data for more informed decision-making.

Augmented Reality (AR) Takeoff

Manual quantity takeoff relies on physical blueprints and handwritten notes, often leading to time-consuming errors and inefficiencies. 5D quantity takeoff integrated with Augmented Reality (AR) technology enables real-time visualization and precise measurement directly on-site, enhancing accuracy and accelerating project timelines.

Automated Clash Detection Takeoff

Automated clash detection takeoff in 5D quantity takeoff significantly enhances accuracy by integrating 3D BIM models with time and cost data, identifying conflicts early to prevent costly rework. Manual quantity takeoff relies on traditional blueprints and is prone to human error, lacking the ability to detect clashes automatically and optimize project timelines.

Parametric Estimation

Manual quantity takeoff relies on labor-intensive measurement from 2D drawings, often leading to inaccuracies and time-consuming revisions. In contrast, 5D quantity takeoff integrates parametric estimation through BIM models, enabling dynamic cost analysis and real-time updates that enhance precision and efficiency in construction project planning.

Revit Plug-in Extraction

Manual quantity takeoff relies heavily on human input and is prone to errors, whereas 5D quantity takeoff using Revit plug-in extraction automates the process by directly pulling accurate quantities from BIM models. This integration enhances cost estimation precision and project scheduling by linking quantities with time and cost data in real-time.

Live Quantification Dashboard

The Live Quantification Dashboard in 5D Quantity Takeoff integrates real-time data updates and visualizations, enabling precise cost estimation and project tracking compared to traditional manual quantity takeoff methods. This digital platform enhances accuracy by automatically linking quantities to scheduling and budgeting, reducing errors and accelerating decision-making processes in construction projects.

Blockchain-Verified Takeoff

Manual Quantity Takeoff relies on traditional methods prone to human error and delays, while 5D Quantity Takeoff integrates project scheduling and cost data for real-time updates. Blockchain-Verified Takeoff enhances 5D processes by ensuring immutable, transparent records of quantities and changes, improving auditability and trust among stakeholders in construction projects.

Cloud-Based 5D Estimating

Cloud-based 5D quantity takeoff integrates time and cost data with 3D models, enabling real-time collaboration and more accurate, dynamic project estimations compared to traditional manual quantity takeoff methods. This advanced approach reduces errors, accelerates the bidding process, and improves resource management by leveraging centralized data accessible from anywhere.

Manual Quantity Takeoff vs 5D Quantity Takeoff Infographic

industrydif.com

industrydif.com