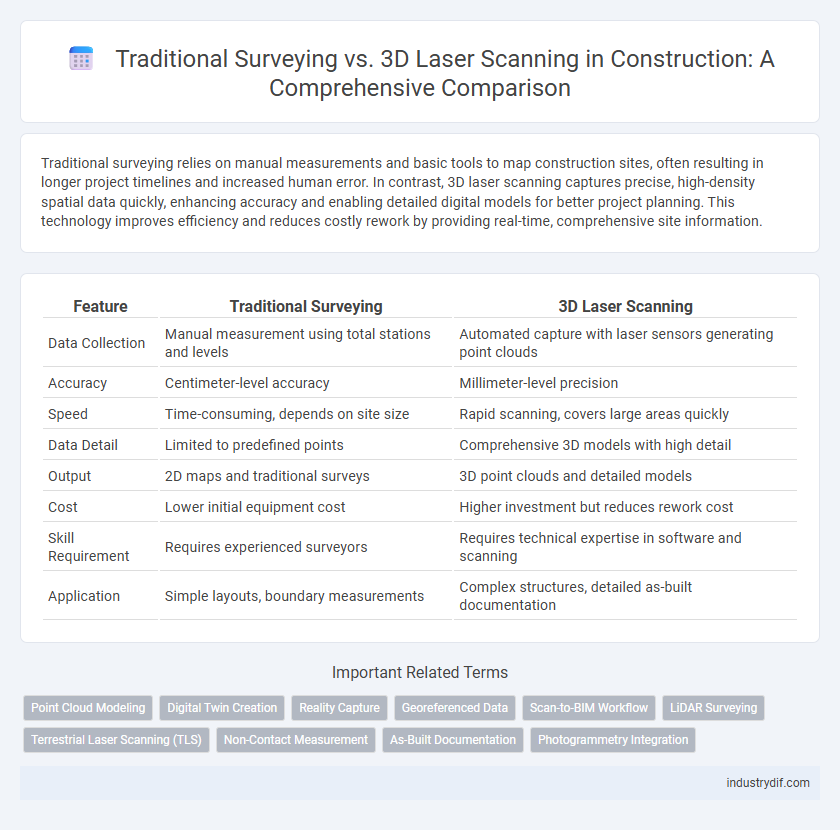

Traditional surveying relies on manual measurements and basic tools to map construction sites, often resulting in longer project timelines and increased human error. In contrast, 3D laser scanning captures precise, high-density spatial data quickly, enhancing accuracy and enabling detailed digital models for better project planning. This technology improves efficiency and reduces costly rework by providing real-time, comprehensive site information.

Table of Comparison

| Feature | Traditional Surveying | 3D Laser Scanning |

|---|---|---|

| Data Collection | Manual measurement using total stations and levels | Automated capture with laser sensors generating point clouds |

| Accuracy | Centimeter-level accuracy | Millimeter-level precision |

| Speed | Time-consuming, depends on site size | Rapid scanning, covers large areas quickly |

| Data Detail | Limited to predefined points | Comprehensive 3D models with high detail |

| Output | 2D maps and traditional surveys | 3D point clouds and detailed models |

| Cost | Lower initial equipment cost | Higher investment but reduces rework cost |

| Skill Requirement | Requires experienced surveyors | Requires technical expertise in software and scanning |

| Application | Simple layouts, boundary measurements | Complex structures, detailed as-built documentation |

Introduction to Surveying Methods in Construction

Traditional surveying in construction relies on manual measurements using tools like theodolites, total stations, and measuring tapes to capture site dimensions and elevations, providing accurate but time-consuming data collection. 3D laser scanning employs LiDAR technology to rapidly generate dense point clouds that create precise digital models of construction sites, enabling faster data acquisition and enhanced accuracy. The integration of 3D laser scanning improves project planning, clash detection, and progress monitoring compared to conventional surveying methods.

What is Traditional Surveying?

Traditional surveying involves using manual tools such as total stations, theodolites, and leveling instruments to measure distances, angles, and elevations on construction sites. This method relies on human interpretation and physical markers, which can be time-consuming and prone to errors in complex terrains. Despite its limitations, traditional surveying remains essential for preliminary site assessments and basic topographical mapping in construction projects.

Fundamentals of 3D Laser Scanning

3D laser scanning utilizes laser beams to capture precise spatial data, creating detailed, high-resolution point clouds that represent physical structures accurately. Unlike traditional surveying methods relying on manual measurements and line-of-sight tools, 3D laser scanning drastically reduces human error and accelerates data collection on complex construction sites. The technology enables comprehensive analysis, from topographic mapping to structural inspections, enhancing project accuracy and efficiency in construction workflows.

Accuracy Comparison: Traditional vs 3D Laser Scanning

Traditional surveying methods typically achieve accuracy within a few millimeters but are often susceptible to human error and environmental conditions. 3D laser scanning offers sub-millimeter precision by capturing millions of data points rapidly, minimizing manual measurements and increasing reliability. This advanced technology enhances project outcomes through highly detailed and accurate spatial data, reducing rework and improving design integration.

Time Efficiency and Project Timelines

Traditional surveying methods often involve manual measurements and multiple site visits, leading to longer data collection times and extended project timelines. In contrast, 3D laser scanning captures precise spatial data rapidly, significantly reducing onsite survey time and accelerating project completion. The enhanced time efficiency of 3D laser scanning enables quicker decision-making and minimizes delays in construction scheduling.

Data Collection and Output Formats

Traditional surveying relies on manual measurements using tools like theodolites and total stations, generating point data often recorded on paper or basic digital formats such as CSV or TXT. In contrast, 3D laser scanning captures millions of data points instantly, producing dense, high-resolution point clouds compatible with advanced BIM software formats like LAS, E57, and PLY. The advanced data capture and versatile output options of 3D laser scanning significantly enhance accuracy and streamline integration with digital construction workflows.

Cost Implications and Budget Considerations

Traditional surveying incurs lower initial equipment costs but often requires more labor hours, leading to higher overall project expenses. 3D laser scanning involves higher upfront investment in advanced technology yet significantly reduces time spent on data collection and minimizes rework, resulting in long-term cost savings. Budget considerations must balance immediate expenditure against efficiency gains and accuracy improvements offered by laser scanning.

Applications in Modern Construction Projects

Traditional surveying remains essential for basic topographic mapping and boundary determination in construction, offering reliable point-to-point measurements for site layout. 3D laser scanning excels in capturing comprehensive, high-density spatial data for complex geometries, enabling precise as-built documentation, clash detection, and BIM integration. Modern construction projects benefit from the combination of traditional accuracy with the advanced visualization and data processing capabilities of 3D laser scanning, improving efficiency and reducing rework.

Limitations and Challenges of Each Method

Traditional surveying relies heavily on manual measurements, which can be time-consuming and prone to human error, especially in complex or large-scale construction sites. 3D laser scanning offers rapid data capture with high accuracy but faces challenges such as high equipment costs, data processing complexity, and limitations in capturing reflective or obstructed surfaces. Both methods may encounter difficulties in adverse weather conditions, impacting data quality and project timelines.

Future Trends: Advancements in Surveying Technologies

Future trends in construction surveying prominently feature advancements like 3D laser scanning, which offers enhanced accuracy, real-time data capture, and comprehensive spatial analysis compared to traditional surveying methods reliant on manual measurements and optical instruments. The integration of Artificial Intelligence and machine learning into 3D scanning technology further accelerates data processing, enabling predictive modeling and automated feature extraction that revolutionizes project planning and execution. As these innovations become more accessible, they drive increased efficiency, reduce human error, and support complex infrastructure development with superior dimensional precision and faster turnaround times.

Related Important Terms

Point Cloud Modeling

Traditional surveying relies on manual measurements and conventional tools, often resulting in less detailed and time-consuming data collection compared to 3D laser scanning. 3D laser scanning generates high-density point cloud models that provide precise, comprehensive spatial data for enhanced accuracy and efficiency in construction project planning and monitoring.

Digital Twin Creation

Traditional surveying methods rely on manual measurements and point data collection, which are time-consuming and prone to human error, limiting their accuracy in digital twin creation for construction projects. In contrast, 3D laser scanning captures high-density spatial data rapidly and precisely, enabling the generation of detailed and accurate digital twins that enhance project visualization, monitoring, and decision-making.

Reality Capture

Traditional surveying relies on manual measurements and basic instruments, which can be time-consuming and less precise for complex construction sites. 3D laser scanning captures millions of accurate data points in real-time, enabling detailed reality capture that enhances project accuracy and reduces rework in construction workflows.

Georeferenced Data

Traditional surveying relies on manual measurements and manual entry of coordinates, often leading to less precise georeferenced data due to human errors and equipment limitations. In contrast, 3D laser scanning captures millions of spatial points instantly, producing highly accurate, georeferenced data sets that enhance construction planning, monitoring, and decision-making processes.

Scan-to-BIM Workflow

Traditional surveying relies on manual measurements and 2D data, often leading to longer project timelines and increased risk of human error. The Scan-to-BIM workflow leverages 3D laser scanning to create highly accurate digital twins, streamlining design, coordination, and construction processes with enhanced precision and efficiency.

LiDAR Surveying

LiDAR surveying utilizes laser pulses to generate precise 3D point clouds of construction sites, enabling faster data capture compared to traditional surveying methods that rely on manual measurements and total stations. This technology enhances accuracy, reduces human error, and facilitates comprehensive site analysis for complex geometries and large-scale infrastructure projects.

Terrestrial Laser Scanning (TLS)

Terrestrial Laser Scanning (TLS) offers precise, high-density point cloud data capturing complex construction site geometries faster than traditional surveying methods reliant on total stations and manual measurements. TLS enhances accuracy in as-built documentation, clash detection, and progress monitoring, significantly reducing human error and onsite time while enabling detailed 3D modeling for effective project management.

Non-Contact Measurement

Traditional surveying relies on contact-based methods such as total stations and leveling instruments, requiring physical access to measurement points, which can be time-consuming and prone to human error. In contrast, 3D laser scanning employs non-contact measurement technology using laser beams to capture precise spatial data quickly and accurately, enhancing safety and efficiency on construction sites.

As-Built Documentation

Traditional surveying relies on manually collected measurements that can introduce human error and take significant time, whereas 3D laser scanning captures millions of precise data points rapidly, producing accurate as-built documentation. This advanced technology enhances project efficiency by creating detailed digital models that improve verification, clash detection, and future renovations.

Photogrammetry Integration

Traditional surveying methods rely on manual measurements and basic optical instruments, which can be time-consuming and less accurate for complex sites, while 3D laser scanning offers rapid, high-precision data capture with detailed point clouds. Integrating photogrammetry with 3D laser scanning enhances data richness by combining accurate spatial measurements and high-resolution imagery, enabling comprehensive 3D models for improved analysis and decision-making in construction projects.

Traditional Surveying vs 3D Laser Scanning Infographic

industrydif.com

industrydif.com