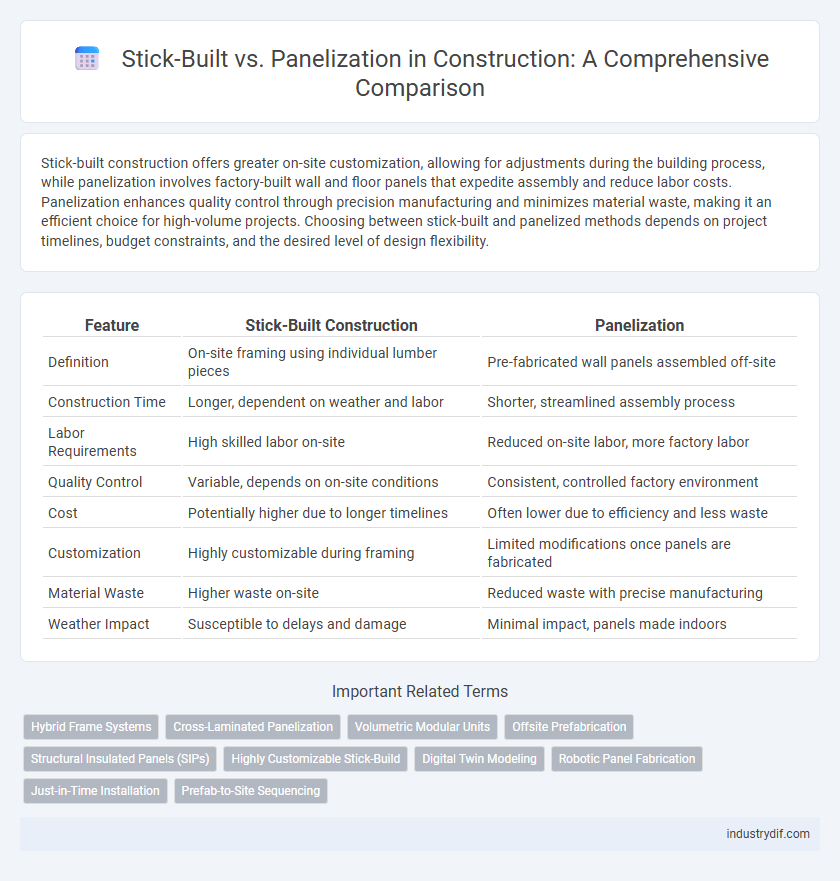

Stick-built construction offers greater on-site customization, allowing for adjustments during the building process, while panelization involves factory-built wall and floor panels that expedite assembly and reduce labor costs. Panelization enhances quality control through precision manufacturing and minimizes material waste, making it an efficient choice for high-volume projects. Choosing between stick-built and panelized methods depends on project timelines, budget constraints, and the desired level of design flexibility.

Table of Comparison

| Feature | Stick-Built Construction | Panelization |

|---|---|---|

| Definition | On-site framing using individual lumber pieces | Pre-fabricated wall panels assembled off-site |

| Construction Time | Longer, dependent on weather and labor | Shorter, streamlined assembly process |

| Labor Requirements | High skilled labor on-site | Reduced on-site labor, more factory labor |

| Quality Control | Variable, depends on on-site conditions | Consistent, controlled factory environment |

| Cost | Potentially higher due to longer timelines | Often lower due to efficiency and less waste |

| Customization | Highly customizable during framing | Limited modifications once panels are fabricated |

| Material Waste | Higher waste on-site | Reduced waste with precise manufacturing |

| Weather Impact | Susceptible to delays and damage | Minimal impact, panels made indoors |

Overview of Stick-Built and Panelization Methods

Stick-built construction involves assembling individual framing components such as studs, joists, and rafters directly on-site, allowing for customization and flexibility in design. Panelization consists of factory-built wall panels transported to the site for rapid assembly, improving construction speed and reducing labor costs. Both methods impact project timelines, construction quality, and material waste management in distinct ways.

Historical Evolution in Construction Techniques

Stick-built construction has dominated residential building since the early 20th century, emphasizing on-site framing with individual lumber pieces assembled manually. Panelization emerged mid-century, introducing factory-produced wall panels that improved construction speed and quality control by minimizing on-site labor. Advances in materials technology and automation continue to drive the shift towards panelization, reflecting a broader industry trend favoring efficiency and sustainability.

Core Differences: Stick-Built vs Panelization

Stick-built construction involves assembling individual framing components on-site, providing flexibility for custom adjustments and complex designs, while panelization pre-fabricates wall panels in a controlled factory environment, enhancing precision and reducing on-site labor time. Stick-built methods typically require longer construction timelines due to on-site assembly and weather dependencies, whereas panelization allows for faster installation and improved quality control through standardized manufacturing processes. Choosing between stick-built and panelization hinges on project size, budget, timeline, and design complexity, with panelization often favored for its efficiency and consistency in large-scale developments.

Material Selection and Sourcing

Material selection in stick-built construction emphasizes on-site procurement of individual framing components like studs, joists, and sheathing, allowing for customization but often leading to variability in quality and availability. Panelization relies on pre-fabricated wall panels produced in controlled factory environments using standardized materials such as engineered wood or structural insulated panels, enhancing consistency and reducing waste. Sourcing for panelized systems often streamlines supply chains with bulk orders from manufacturers, contrasting with stick-built methods where multiple suppliers and local availability can affect timelines and costs.

Labor Requirements and Skilled Trades

Stick-built construction demands a higher labor input with skilled carpenters on-site for framing, cutting, and assembling individual components, leading to longer build times. Panelization reduces on-site labor by prefabricating wall and floor panels in controlled factory environments with specialized machinery and skilled technicians, streamlining installation and improving quality control. The shift from stick-built to panelized methods minimizes dependency on fluctuating labor availability and skilled trade shortages while enhancing construction efficiency.

Construction Timelines and Project Scheduling

Stick-built construction typically requires longer timelines due to on-site framing and sequential assembly, which can be affected by weather and site conditions. Panelization streamlines project scheduling by fabricating wall panels off-site in controlled environments, reducing on-site labor and accelerating installation. This prefabrication method shortens overall construction duration, improves timeline predictability, and minimizes weather-related delays.

Cost Analysis: Upfront and Lifecycle Expenses

Stick-built construction typically involves higher upfront labor costs due to on-site assembly and customization, but offers flexibility in design modifications during the build. Panelization reduces initial labor expenses through factory-prepared wall sections, accelerating project timelines and minimizing on-site waste, which can lower overall lifecycle costs. Lifecycle expenses favor panelization by enhancing energy efficiency and reducing maintenance through precision manufacturing and consistent quality control.

Quality Control and On-Site Challenges

Stick-built construction allows for greater flexibility in quality control through continuous on-site inspections, enabling immediate adjustments to materials and methods. Panelization reduces on-site challenges by fabricating wall panels in controlled factory environments, minimizing weather delays and site variability. Both approaches impact project timelines and quality assurance, with stick-built offering real-time oversight while panelization ensures precision and consistency before delivery.

Sustainability and Environmental Impact

Stick-built construction typically generates more on-site waste and consumes higher energy due to extended build times, increasing its environmental footprint. Panelization reduces waste by factory precision cutting and allows for faster assembly, lowering energy use and minimizing site disturbance. Emphasizing sustainable materials in panelized systems further enhances their environmental benefits compared to traditional stick-built methods.

Future Trends in Construction Methods

Future trends in construction methods emphasize increased adoption of panelization due to its efficiency, reduced labor costs, and faster assembly times compared to traditional stick-built techniques. Integration of advanced materials like cross-laminated timber (CLT) and prefabricated modules is driving innovation in off-site manufacturing, promoting sustainability and precision in building processes. Smart construction technologies, including automation and digital modeling, further enhance the scalability and quality control of panelized systems, shaping the future of residential and commercial construction.

Related Important Terms

Hybrid Frame Systems

Hybrid frame systems combine stick-built and panelization techniques to optimize structural strength and construction speed, using stick framing for complex architectural details and prefabricated panels for uniform sections. This approach reduces on-site labor costs and minimizes material waste while enhancing design flexibility and overall project efficiency.

Cross-Laminated Panelization

Cross-laminated timber (CLT) panelization offers superior structural strength, precision, and faster on-site assembly compared to traditional stick-built construction, reducing labor costs and construction time. CLT panels provide enhanced sustainability with engineered wood's carbon sequestration benefits while improving energy efficiency through airtight building envelopes.

Volumetric Modular Units

Volumetric modular units offer faster construction times and enhanced quality control compared to traditional stick-built methods by assembling complete sections off-site, reducing on-site labor and weather-related delays. This panelization approach streamlines project schedules and minimizes material waste, making it an efficient solution for scalable construction projects.

Offsite Prefabrication

Offsite prefabrication enhances construction efficiency by assembling stick-built components or modular panels in controlled factory environments, reducing on-site labor and waste. Panelization offers faster installation times and improved quality control compared to traditional stick-built methods, making it a preferred choice for large-scale residential and commercial projects.

Structural Insulated Panels (SIPs)

Structural Insulated Panels (SIPs) offer superior energy efficiency and faster installation compared to traditional stick-built construction by integrating insulation and structural components into prefabricated panels. These panels enhance building strength, reduce waste, and improve airtightness, making SIPs a cost-effective solution in modern construction projects.

Highly Customizable Stick-Build

Stick-built construction offers unparalleled flexibility for highly customizable home designs, allowing precise modifications to architectural details, layouts, and structural components on-site. This method supports unique features and non-standard dimensions that panelization cannot easily accommodate, making it ideal for bespoke residential projects.

Digital Twin Modeling

Digital twin modeling in construction enhances the precision of both stick-built and panelization methods by creating real-time virtual replicas of the building process, enabling detailed monitoring and adjustments. This technology optimizes resource allocation, reduces errors, and improves collaboration between design and construction phases, significantly accelerating project timelines.

Robotic Panel Fabrication

Robotic panel fabrication in panelization significantly enhances construction efficiency by automating precise cutting and assembly of wall panels, reducing material waste and labor costs compared to traditional stick-built methods. This technology enables faster project completion with consistent quality control, making it ideal for large-scale residential and commercial builds.

Just-in-Time Installation

Stick-built construction allows for greater flexibility on-site but often requires longer installation times due to sequential assembly processes. Panelization streamlines just-in-time installation by delivering pre-fabricated wall panels directly to the site, reducing labor costs and minimizing delays caused by weather or material shortages.

Prefab-to-Site Sequencing

Stick-built construction involves on-site assembly of individual components, allowing flexible scheduling but often extending project timelines due to weather and labor variability. Panelization accelerates prefab-to-site sequencing by delivering pre-assembled wall and floor panels, reducing on-site work and improving construction efficiency and quality control.

Stick-Built vs Panelization Infographic

industrydif.com

industrydif.com