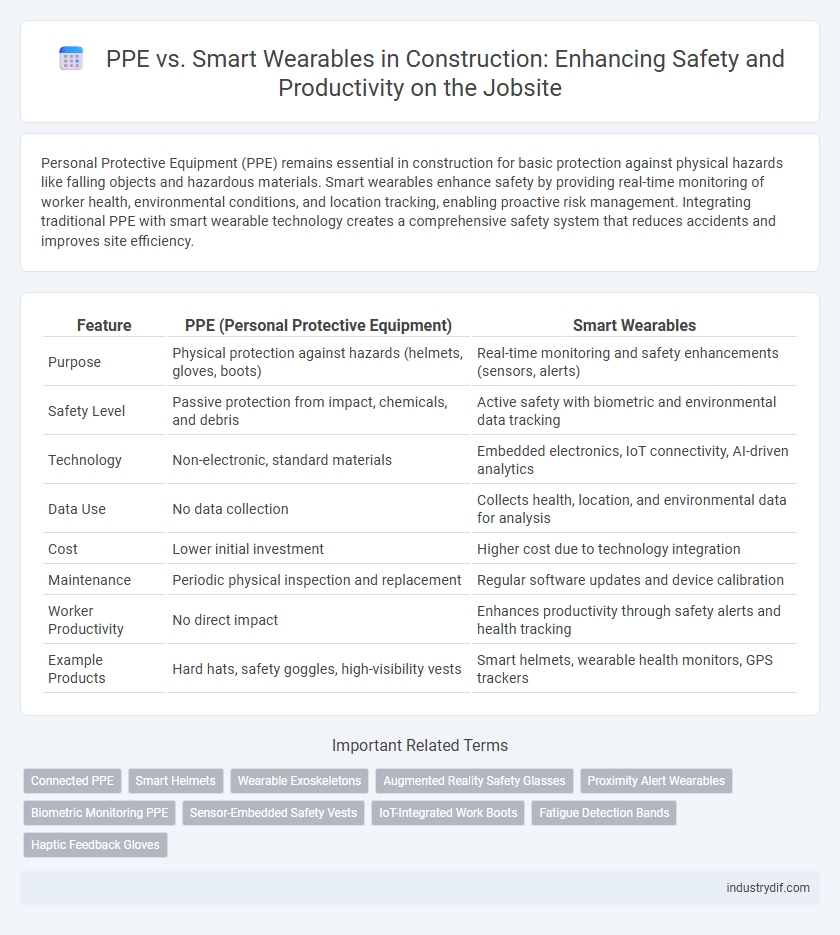

Personal Protective Equipment (PPE) remains essential in construction for basic protection against physical hazards like falling objects and hazardous materials. Smart wearables enhance safety by providing real-time monitoring of worker health, environmental conditions, and location tracking, enabling proactive risk management. Integrating traditional PPE with smart wearable technology creates a comprehensive safety system that reduces accidents and improves site efficiency.

Table of Comparison

| Feature | PPE (Personal Protective Equipment) | Smart Wearables |

|---|---|---|

| Purpose | Physical protection against hazards (helmets, gloves, boots) | Real-time monitoring and safety enhancements (sensors, alerts) |

| Safety Level | Passive protection from impact, chemicals, and debris | Active safety with biometric and environmental data tracking |

| Technology | Non-electronic, standard materials | Embedded electronics, IoT connectivity, AI-driven analytics |

| Data Use | No data collection | Collects health, location, and environmental data for analysis |

| Cost | Lower initial investment | Higher cost due to technology integration |

| Maintenance | Periodic physical inspection and replacement | Regular software updates and device calibration |

| Worker Productivity | No direct impact | Enhances productivity through safety alerts and health tracking |

| Example Products | Hard hats, safety goggles, high-visibility vests | Smart helmets, wearable health monitors, GPS trackers |

Understanding Traditional PPE in Construction

Traditional Personal Protective Equipment (PPE) in construction includes helmets, gloves, steel-toed boots, high-visibility vests, and safety goggles designed to protect workers from physical hazards like falling objects, sharp materials, and electrical risks. These equipment items provide essential barriers against injuries but lack real-time monitoring capabilities or data collection features. Understanding the limitations of conventional PPE highlights the growing need for integrating smart wearables that offer enhanced safety through sensor technology and hazard detection.

Introduction to Smart Wearables for Construction Safety

Smart wearables in construction enhance safety by providing real-time monitoring of workers' health and environmental conditions, surpassing traditional PPE's passive protection. Devices such as smart helmets, vests with sensors, and wearable GPS trackers detect hazards like falls, excessive fatigue, and toxic gas exposure, enabling immediate alerts and prevention. Integration of IoT and AI in these wearables allows for data-driven safety management, reducing accidents and improving compliance on construction sites.

Key Differences Between PPE and Smart Wearables

Personal Protective Equipment (PPE) primarily functions as physical barriers safeguarding construction workers from environmental hazards such as impact, chemicals, and falling debris, whereas smart wearables incorporate technology to monitor health metrics, environmental conditions, and worker location in real-time. PPE includes items like helmets, gloves, and safety goggles designed for compliance with safety standards, while smart wearables feature sensors, GPS, and connectivity to provide data-driven insights enhancing situational awareness and accident prevention. The key difference lies in PPE's passive protective role versus smart wearables' active monitoring and communication capabilities enhancing overall site safety management.

Advantages of Traditional PPE

Traditional PPE in construction offers reliable physical protection against hazards such as falling debris, sharp objects, and chemical exposure, ensuring worker safety on-site. It is cost-effective, easy to deploy, and does not depend on batteries or software updates, making it highly dependable in varying work environments. Furthermore, PPE is widely accepted and mandated by safety regulations, supporting compliance and reducing liability risks for construction companies.

Benefits of Smart Wearables in Construction

Smart wearables in construction enhance worker safety by providing real-time biometric monitoring and hazard detection, reducing accident risks on-site. Unlike traditional PPE, these devices offer continuous data collection and instant alerts for environmental dangers such as gas leaks or structural weaknesses. Integration with IoT systems allows for improved project management through tracking location, productivity, and equipment usage.

Integration of Smart Technology with PPE

Integrating smart technology with Personal Protective Equipment (PPE) revolutionizes construction safety by embedding sensors that monitor environmental hazards and worker health metrics in real time. Smart wearables such as helmets with impact detection, smart vests with GPS tracking, and breathable gloves with biometric sensors enhance situational awareness and enable immediate response to accidents or exposure risks. This fusion of PPE and IoT-driven smart devices significantly reduces workplace injuries and improves compliance with safety regulations on construction sites.

Cost Comparison: PPE vs Smart Wearables

Traditional Personal Protective Equipment (PPE) typically involves lower upfront costs but incurs recurring expenses for replacement and maintenance, while smart wearables have higher initial investment due to advanced technology integration such as sensors and connectivity. Over time, smart wearables can reduce overall costs by enabling real-time monitoring, improving worker safety, and minimizing downtime or accident-related expenses. Cost comparison should also factor in the potential for enhanced productivity and data-driven safety improvements unique to smart wearables in construction environments.

Regulatory Standards for PPE and Smart Wearables

Regulatory standards for Personal Protective Equipment (PPE) in construction are governed by OSHA and ANSI, ensuring compliance with safety criteria such as impact resistance and durability. Smart wearables, classified under both PPE and electronic device regulations, must meet cybersecurity guidelines and interoperability standards set by agencies like the FCC and ISO. Integration of smart technology into PPE requires adherence to dual compliance frameworks to guarantee both physical protection and data security on construction sites.

Challenges and Limitations of Smart Wearables

Smart wearables in construction face significant challenges including limited battery life, data privacy concerns, and interoperability issues with existing safety systems. The high cost of deployment and maintenance restricts widespread adoption on large-scale industrial sites. Furthermore, environmental factors such as dust, moisture, and physical impacts can impair the durability and functionality of these devices.

Future Trends in Construction Safety Technology

Smart wearables in construction are revolutionizing safety by integrating real-time hazard detection and biometric monitoring, surpassing traditional PPE limitations. Emerging trends highlight AI-powered helmets and smart vests that communicate environmental risks and worker health data to centralized safety systems. These innovations are set to reduce accidents, enhance compliance, and drive a new era of proactive construction site safety management.

Related Important Terms

Connected PPE

Connected PPE integrates traditional personal protective equipment with smart wearable technology to enhance worker safety on construction sites by providing real-time monitoring of environmental hazards and vital signs. This fusion improves compliance, reduces accidents, and enables data-driven decision-making for proactive risk management.

Smart Helmets

Smart helmets in construction integrate advanced sensors and augmented reality to enhance worker safety by providing real-time hazard detection and communication capabilities, surpassing traditional PPE in proactive risk management. These helmets improve situational awareness, reduce accident rates, and enable data-driven safety protocols, revolutionizing on-site protection standards.

Wearable Exoskeletons

Wearable exoskeletons in construction significantly enhance worker safety and productivity by reducing physical strain and preventing musculoskeletal injuries during heavy lifting tasks. These smart wearable devices integrate ergonomic design with advanced sensors to support posture and movement, offering real-time feedback and injury risk reduction.

Augmented Reality Safety Glasses

Augmented Reality (AR) safety glasses in construction enhance traditional personal protective equipment (PPE) by providing real-time hazard identification, hands-free access to project data, and improved situational awareness through layered digital information. These smart wearables increase worker safety and productivity by reducing human error and enabling immediate response to on-site risks.

Proximity Alert Wearables

Proximity alert wearables enhance construction site safety by providing real-time hazard detection, reducing the risk of accidents compared to traditional PPE that relies on visual or manual awareness. These smart wearables utilize sensors and Bluetooth technology to alert workers of nearby heavy machinery or hazardous zones, improving proactive risk management.

Biometric Monitoring PPE

Biometric monitoring PPE integrates advanced sensors to continuously track workers' vital signs such as heart rate, body temperature, and fatigue levels, enhancing safety by providing real-time health data on construction sites. These smart wearables surpass traditional PPE by enabling early detection of potential health risks, reducing accidents, and improving emergency response efficiency.

Sensor-Embedded Safety Vests

Sensor-embedded safety vests integrate advanced PPE with IoT technology, enabling real-time monitoring of environmental hazards and worker vital signs to enhance construction site safety. These smart wearables increase injury prevention by providing instant alerts for temperature extremes, toxic gas exposure, and falls, surpassing traditional PPE's passive protection.

IoT-Integrated Work Boots

IoT-integrated work boots enhance construction site safety by providing real-time location tracking, hazard detection, and worker health monitoring, surpassing traditional PPE's static protection. These smart wearables utilize embedded sensors and connectivity to deliver actionable insights, reducing accidents and improving response times on-site.

Fatigue Detection Bands

Fatigue detection bands in construction PPE integrate biometric sensors to monitor workers' vital signs and alert supervisors to early signs of fatigue, reducing accident risks and improving on-site safety. These smart wearables offer real-time data analysis, surpassing traditional PPE by enhancing worker health monitoring and enabling proactive intervention.

Haptic Feedback Gloves

Haptic feedback gloves in construction enhance worker safety and precision by providing tactile sensations that simulate real-world touch, enabling better handling of tools and materials in hazardous environments. Unlike traditional PPE, these smart wearables integrate advanced sensors and real-time data, improving situational awareness and reducing accident risks on construction sites.

PPE vs Smart Wearables Infographic

industrydif.com

industrydif.com