Concrete offers versatility and cost-effectiveness for a wide range of construction projects, providing adequate strength and durability for most standard applications. Ultra-High Performance Concrete (UHPC) outperforms traditional concrete with superior compressive strength, enhanced durability, and improved resistance to environmental stressors, making it ideal for high-load structures and long-lasting infrastructure. Choosing between concrete and UHPC depends on project requirements, budget constraints, and desired longevity.

Table of Comparison

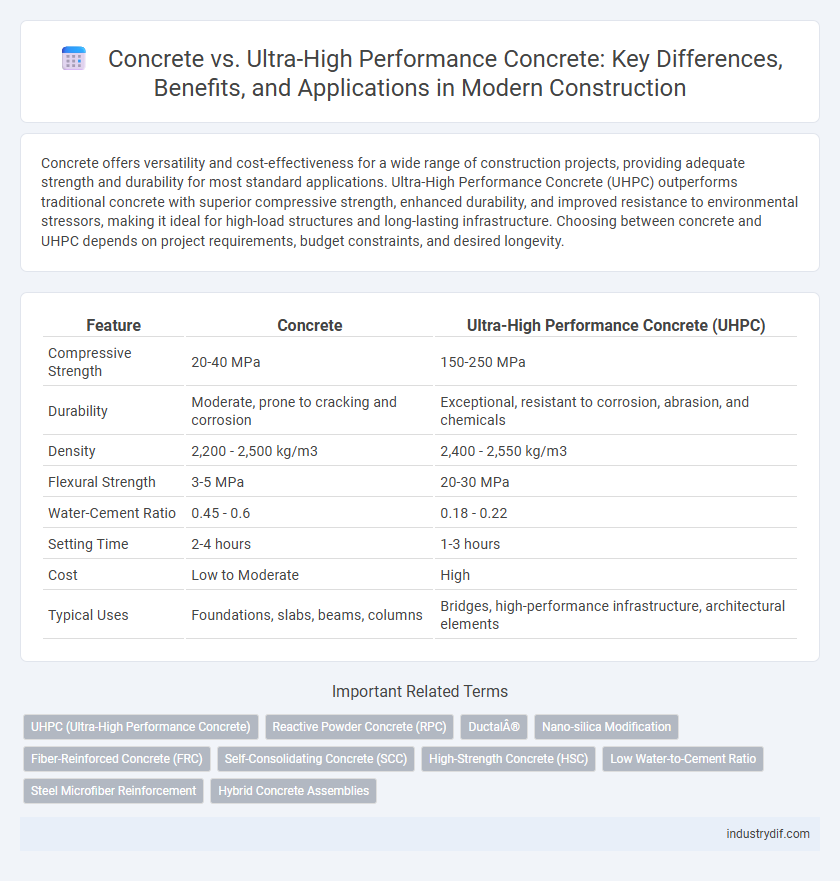

| Feature | Concrete | Ultra-High Performance Concrete (UHPC) |

|---|---|---|

| Compressive Strength | 20-40 MPa | 150-250 MPa |

| Durability | Moderate, prone to cracking and corrosion | Exceptional, resistant to corrosion, abrasion, and chemicals |

| Density | 2,200 - 2,500 kg/m3 | 2,400 - 2,550 kg/m3 |

| Flexural Strength | 3-5 MPa | 20-30 MPa |

| Water-Cement Ratio | 0.45 - 0.6 | 0.18 - 0.22 |

| Setting Time | 2-4 hours | 1-3 hours |

| Cost | Low to Moderate | High |

| Typical Uses | Foundations, slabs, beams, columns | Bridges, high-performance infrastructure, architectural elements |

Introduction to Concrete and Ultra-High Performance Concrete

Concrete, a composite material composed of cement, water, aggregates, and often admixtures, is widely used in construction due to its strength, durability, and versatility. Ultra-High Performance Concrete (UHPC) represents an advanced category of concrete with superior mechanical properties, including compressive strengths exceeding 150 MPa and enhanced durability from optimized particle packing and fiber reinforcement. UHPC's microstructure results in exceptional resistance to environmental degradation, making it ideal for infrastructure requiring extended service life and minimal maintenance.

Composition Differences: Conventional vs. UHPC

Conventional concrete primarily consists of cement, water, coarse aggregates, and fine aggregates, with typical compressive strengths ranging from 20 to 40 MPa. Ultra-High Performance Concrete (UHPC) incorporates a refined particle packing system using fine powders such as silica fume and quartz, along with superplasticizers and steel fibers, resulting in compressive strengths exceeding 150 MPa and significantly enhanced durability. The optimized microstructure of UHPC reduces porosity and improves tensile strength, making it suitable for advanced structural applications requiring superior performance and longevity.

Mechanical Properties and Strength Comparison

Ultra-High Performance Concrete (UHPC) demonstrates significantly superior mechanical properties compared to standard concrete, with compressive strengths exceeding 150 MPa, while conventional concrete typically ranges between 20 to 40 MPa. UHPC's enhanced microstructure and fiber reinforcement provide exceptional tensile strength and durability, enabling superior resistance to cracking and increased longevity in structural applications. This advanced composite material offers increased flexural strength and toughness, making it ideal for infrastructure requiring high load-bearing capacity and extended service life.

Durability and Longevity Factors

Ultra-High Performance Concrete (UHPC) exhibits significantly superior durability compared to traditional concrete due to its dense microstructure and enhanced resistance to chemical attacks, abrasion, and freeze-thaw cycles. UHPC's longevity is extended by its low permeability, reducing water ingress and mitigating corrosion risks for embedded steel reinforcements. These factors collectively result in longer service life and reduced maintenance costs for infrastructure projects using UHPC.

Workability and Placement Techniques

Ultra-high performance concrete (UHPC) offers superior workability compared to conventional concrete due to its optimized particle packing and reduced water-to-cement ratio, allowing for easier flow in complex formworks. Placement techniques for UHPC require meticulous control, such as self-consolidation methods and careful vibration to avoid segregation and ensure uniform density. Standard concrete typically permits more traditional placement approaches like pouring and mechanical vibration but may suffer from lower fluidity and increased labor during finishing.

Cost Analysis: Initial vs. Lifecycle Costs

Ultra-High Performance Concrete (UHPC) involves higher initial costs compared to conventional concrete due to specialized materials and production techniques. However, UHPC's superior durability, reduced maintenance, and extended lifespan significantly lower lifecycle costs by minimizing repair frequency and enhancing structural resilience. Investing in UHPC offers long-term economic benefits despite the upfront expense, especially in infrastructure projects demanding high performance and durability.

Environmental Impact and Sustainability

Ultra-High Performance Concrete (UHPC) significantly reduces environmental impact by using less material due to its superior strength and durability compared to traditional concrete, resulting in lower carbon emissions over its lifetime. UHPC's dense microstructure enhances resistance to corrosion and weathering, extending the lifespan of structures and minimizing the need for repairs and replacements. Sustainable construction leverages UHPC to optimize resource efficiency while meeting stringent environmental regulations and reducing the overall carbon footprint of infrastructure projects.

Applications in Modern Construction Projects

Ultra-high performance concrete (UHPC) is increasingly favored in modern construction projects for its exceptional strength, durability, and resistance to environmental stressors compared to traditional concrete. This advanced material enables the creation of thinner, lighter structural elements, including bridge decks, facades, and seismic-resistant components, allowing for innovative architectural designs and extended service life. Applications span infrastructure, high-rise buildings, and complex precast elements where enhanced mechanical properties and longevity are critical.

Limitations and Challenges of UHPC

Ultra-High Performance Concrete (UHPC) faces limitations such as high material costs and complex manufacturing processes, restricting its widespread adoption in standard construction projects. Its dense microstructure demands precise quality control and specialized curing methods to achieve optimal performance, challenging on-site applications. Additionally, the limited availability of standardized design codes for UHPC complicates engineering integration and long-term durability assessments.

Future Trends in Concrete Technology

Ultra-High Performance Concrete (UHPC) is revolutionizing the construction industry by offering superior strength, durability, and environmental resistance compared to traditional concrete. Future trends focus on integrating nanotechnology and advanced fiber reinforcement in UHPC to enhance sustainability and performance in infrastructure projects. Adoption of UHPC enables longer service life and reduced maintenance costs, driving its demand in smart city developments and resilient building designs.

Related Important Terms

UHPC (Ultra-High Performance Concrete)

Ultra-High Performance Concrete (UHPC) offers exceptional compressive strength exceeding 150 MPa and superior durability compared to traditional concrete, enhancing structural longevity and resistance to environmental factors. Its dense microstructure and advanced fiber reinforcement significantly reduce permeability and improve tensile strength, making UHPC ideal for critical infrastructure, bridges, and architectural applications requiring minimal maintenance and extended service life.

Reactive Powder Concrete (RPC)

Reactive Powder Concrete (RPC), a type of Ultra-High Performance Concrete (UHPC), offers superior compressive strength exceeding 200 MPa and enhanced durability compared to traditional concrete, making it ideal for advanced construction applications requiring exceptional load-bearing capacity and longevity. Featuring a dense microstructure with minimized porosity due to optimized particle packing and steel fiber reinforcement, RPC exhibits remarkable resistance to chemical attack and abrasion, significantly extending the lifespan of structural components.

Ductal®

Ultra-High Performance Concrete (UHPC), exemplified by Ductal(r), offers superior compressive strengths exceeding 150 MPa and enhanced durability compared to traditional concrete, making it ideal for demanding structural applications. Its dense microstructure and optimized fiber reinforcement provide exceptional ductility and resistance to environmental degradation, significantly extending the lifespan of infrastructure projects.

Nano-silica Modification

Nano-silica modification significantly enhances Ultra-High Performance Concrete (UHPC) by refining its microstructure, increasing compressive strength beyond 150 MPa and improving durability through pore filling and reduced permeability. Unlike conventional concrete with typical compressive strength of 20-40 MPa, nano-silica in UHPC promotes hydration and densifies the cement matrix, resulting in superior mechanical properties and longevity for demanding construction applications.

Fiber-Reinforced Concrete (FRC)

Fiber-Reinforced Concrete (FRC) enhances traditional concrete's durability and tensile strength by embedding fibers such as steel, glass, or synthetic materials, significantly reducing cracking and improving impact resistance. Ultra-High Performance Concrete (UHPC) incorporates optimized FRC technology with a densely packed microstructure and higher fiber content, resulting in exceptional compressive strength above 150 MPa and superior longevity, making it ideal for critical infrastructure projects.

Self-Consolidating Concrete (SCC)

Self-Consolidating Concrete (SCC) is a highly flowable, non-segregating concrete that eliminates the need for mechanical vibration, providing superior surface finishes and faster construction times compared to traditional concrete. Ultra-High Performance Concrete (UHPC) enhances SCC properties with exceptional compressive strength exceeding 150 MPa, improved durability, and greater resistance to environmental stressors, making it ideal for infrastructure and architectural applications requiring longevity and minimal maintenance.

High-Strength Concrete (HSC)

Ultra-High Performance Concrete (UHPC) significantly surpasses traditional High-Strength Concrete (HSC) in compressive strength, often exceeding 150 MPa compared to HSC's typical range of 40-100 MPa, offering enhanced durability, reduced permeability, and superior resistance to environmental stressors. The dense microstructure of UHPC, achieved through optimized particle packing and fiber reinforcement, results in exceptional mechanical properties and extended lifespan in critical infrastructure projects.

Low Water-to-Cement Ratio

Ultra-High Performance Concrete (UHPC) features a significantly lower water-to-cement ratio, typically below 0.25, compared to traditional concrete's 0.40 to 0.60, resulting in superior strength, durability, and reduced permeability. This low water-to-cement ratio in UHPC enhances its microstructure density, making it ideal for high-performance construction applications requiring exceptional load-bearing capacity and resistance to environmental degradation.

Steel Microfiber Reinforcement

Steel microfiber reinforcement in ultra-high performance concrete (UHPC) significantly enhances its tensile strength and crack resistance compared to traditional concrete, enabling thinner, more durable structural elements. This reinforcement improves the material's ductility and impact resistance, making UHPC ideal for advanced construction applications requiring superior durability and longevity.

Hybrid Concrete Assemblies

Hybrid concrete assemblies combine traditional concrete's cost-effectiveness with ultra-high performance concrete's (UHPC) superior strength and durability, optimizing structural integrity and longevity in construction projects. Incorporating UHPC in critical load-bearing areas enhances crack resistance and reduces maintenance costs, making hybrid systems ideal for infrastructure requiring advanced performance and cost-efficient solutions.

Concrete vs Ultra-High Performance Concrete Infographic

industrydif.com

industrydif.com