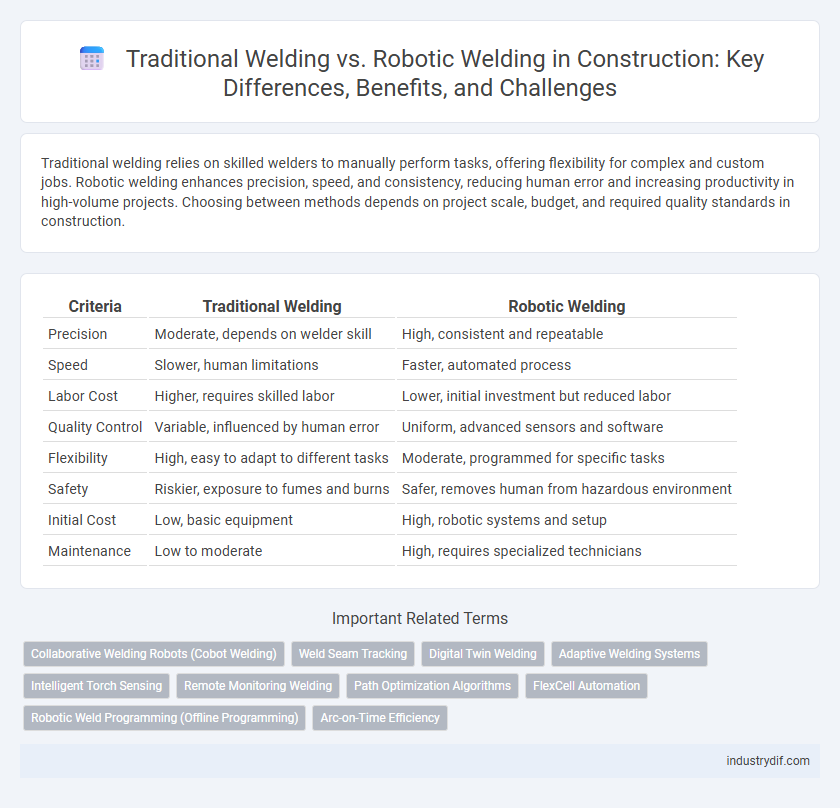

Traditional welding relies on skilled welders to manually perform tasks, offering flexibility for complex and custom jobs. Robotic welding enhances precision, speed, and consistency, reducing human error and increasing productivity in high-volume projects. Choosing between methods depends on project scale, budget, and required quality standards in construction.

Table of Comparison

| Criteria | Traditional Welding | Robotic Welding |

|---|---|---|

| Precision | Moderate, depends on welder skill | High, consistent and repeatable |

| Speed | Slower, human limitations | Faster, automated process |

| Labor Cost | Higher, requires skilled labor | Lower, initial investment but reduced labor |

| Quality Control | Variable, influenced by human error | Uniform, advanced sensors and software |

| Flexibility | High, easy to adapt to different tasks | Moderate, programmed for specific tasks |

| Safety | Riskier, exposure to fumes and burns | Safer, removes human from hazardous environment |

| Initial Cost | Low, basic equipment | High, robotic systems and setup |

| Maintenance | Low to moderate | High, requires specialized technicians |

Introduction to Welding Methods in Construction

Traditional welding in construction relies on skilled labor using manual techniques such as Shielded Metal Arc Welding (SMAW) and Gas Metal Arc Welding (GMAW) for precise metal joining. Robotic welding utilizes automated systems equipped with programmable robots to enhance consistency, speed, and safety in repetitive welding tasks. The choice between traditional and robotic welding depends on project scale, complexity, and budget considerations within the construction industry.

Overview of Traditional Welding Techniques

Traditional welding techniques in construction predominantly include arc welding, MIG (Metal Inert Gas) welding, and TIG (Tungsten Inert Gas) welding, each leveraging manual skill for joining metal components. These methods rely on a skilled welder's ability to control heat, filler material, and welding speed to create strong, durable bonds essential for structural integrity. Despite advancements in automation, traditional welding remains vital for complex, custom, or low-volume fabrication tasks where precision and flexibility are critical.

The Rise of Robotic Welding in Construction

Robotic welding in construction has surged due to its precision, speed, and consistency, outperforming traditional welding methods in complex structural assemblies. Integration of advanced sensors and AI enables robotic systems to adapt to varied construction materials and designs, significantly reducing human error and enhancing safety on-site. As construction projects demand higher efficiency and quality, robotic welding continues to revolutionize industry standards and productivity metrics.

Precision and Accuracy: Human vs Machine

Robotic welding delivers superior precision and accuracy compared to traditional welding, consistently producing uniform welds with minimal defects due to advanced sensors and programmed controls. Human welders, while skilled, are more prone to variability caused by fatigue, environmental factors, and manual technique differences. In high-precision construction projects, robotic welding enhances structural integrity and reduces rework by maintaining exact measurements and consistent heat application.

Productivity and Speed in Welding Processes

Robotic welding significantly enhances productivity by enabling continuous, high-speed operations with consistent precision, reducing cycle times compared to traditional welding methods. Traditional welding relies heavily on skilled labor and manual processes, often resulting in slower production rates and greater variability in weld quality. Increased automation through robotic welding minimizes errors and rework, leading to faster project completion and improved overall efficiency in construction welding tasks.

Cost Analysis: Labor, Equipment, and Maintenance

Traditional welding involves higher labor costs due to skilled manual workers required for each weld, while robotic welding reduces labor expenses by automating repetitive tasks. Equipment costs for robotic welding are initially higher, involving advanced machinery and programming, but these are offset over time by increased efficiency and reduced error rates. Maintenance expenses for traditional welding are generally lower in equipment upkeep but higher in labor downtime, whereas robotic systems demand specialized maintenance and software updates, balancing long-term cost efficiency.

Safety Considerations in Welding Operations

Traditional welding in construction poses higher risks of exposure to fumes, burns, and eye damage due to close human proximity to welding arcs, requiring stringent personal protective equipment (PPE) and ventilation systems. Robotic welding significantly reduces these safety hazards by automating the process within enclosed environments, minimizing direct human contact with dangerous elements. Enhanced precision and consistency of robotic welding also lower the likelihood of accidents caused by operator error, improving overall site safety standards.

Skill Requirements and Workforce Implications

Traditional welding demands highly skilled artisans with extensive hands-on experience to ensure precision and safety, often requiring years of apprenticeship and certification. Robotic welding minimizes the need for manual dexterity, shifting the workforce demand toward technicians skilled in programming, maintenance, and operation of automated systems. This transition reshapes construction labor dynamics, favoring technical expertise over manual welding craftsmanship and influencing workforce training programs.

Quality Control and Consistency in Welds

Robotic welding provides superior quality control by ensuring precise, repeatable welds with minimal human error, critical for maintaining structural integrity in construction projects. Traditional welding depends heavily on the skill and consistency of individual welders, often resulting in variability in weld strength and appearance. Automated systems incorporate real-time monitoring and adjustments, enhancing consistency and reducing defects, which is essential for meeting construction industry standards.

Future Trends in Welding Technology for Construction

Robotic welding is revolutionizing construction by delivering higher precision, consistent quality, and enhanced safety compared to traditional welding methods. Future trends emphasize the integration of AI-driven robotic systems and real-time monitoring sensors, enabling adaptive welding processes that improve efficiency and reduce human error. Advances in automation and machine learning are shaping welding technology to address complex construction demands while minimizing costs and environmental impact.

Related Important Terms

Collaborative Welding Robots (Cobot Welding)

Collaborative welding robots (cobot welding) enhance construction efficiency by combining traditional welding precision with automated consistency, enabling safer, faster, and higher-quality welds on complex structural components. Integrating cobots reduces human error and operator fatigue while maintaining flexibility on-site, transforming conventional welding processes into advanced, scalable solutions for modern construction projects.

Weld Seam Tracking

Traditional welding relies on skilled operators for weld seam tracking, which can lead to inconsistencies and increased inspection time. Robotic welding uses advanced sensors and real-time feedback systems to precisely track weld seams, ensuring higher accuracy and uniformity in construction projects.

Digital Twin Welding

Traditional welding relies heavily on manual skill and lacks real-time monitoring, often resulting in inconsistencies and increased errors. Digital Twin Welding integrates robotic systems with virtual simulations, enabling precise process control, predictive maintenance, and optimized weld quality through continuous data feedback and real-time adjustments.

Adaptive Welding Systems

Adaptive welding systems enhance both traditional and robotic welding processes by continuously monitoring and adjusting welding parameters in real-time to improve accuracy and reduce defects. These systems utilize sensors and AI algorithms to adapt to variable joint conditions, increasing efficiency and weld quality in complex construction projects.

Intelligent Torch Sensing

Intelligent torch sensing in robotic welding enhances precision and real-time monitoring by detecting torch position, temperature, and arc length, reducing defects and improving weld quality compared to traditional welding methods. This technology enables adaptive control and consistent performance, minimizing human error and increasing efficiency on construction sites.

Remote Monitoring Welding

Traditional welding relies heavily on manual skill and direct supervision, often limiting real-time quality control and increasing the risk of human error. Robotic welding with remote monitoring technology enables precise, consistent welds through automated processes while allowing supervisors to oversee operations remotely, enhancing efficiency and reducing downtime in construction projects.

Path Optimization Algorithms

Path optimization algorithms in robotic welding significantly enhance precision and efficiency by calculating the shortest and most effective welding paths, reducing material waste and cycle time compared to traditional welding methods. Traditional welding relies heavily on skilled labor for path accuracy, often leading to inconsistencies and slower production rates, whereas robotic welding integrates advanced algorithms to ensure consistent weld quality and optimized operational workflows.

FlexCell Automation

FlexCell Automation integrates robotic welding to enhance precision, consistency, and productivity in construction projects, reducing human error and labor costs compared to traditional welding. This advanced automation system adapts to complex welding tasks with programmable flexibility, streamlining fabrication and increasing overall efficiency on job sites.

Robotic Weld Programming (Offline Programming)

Robotic weld programming, specifically offline programming, enables the creation and simulation of weld paths in virtual environments, drastically reducing on-site downtime and increasing precision in construction projects. This method integrates 3D modeling and CAD data to optimize weld quality and operational efficiency compared to traditional welding techniques.

Arc-on-Time Efficiency

Traditional welding typically exhibits lower arc-on-time efficiency due to manual setup and operator fatigue, limiting productivity on construction projects. Robotic welding enhances arc-on-time by delivering consistent, continuous operation with precise control, significantly increasing welding speed and reducing downtime.

Traditional Welding vs Robotic Welding Infographic

industrydif.com

industrydif.com