Generators convert mechanical energy into electrical energy using rotating components and electromagnetic induction, making them suitable for large-scale power production. Solid-state generators rely on semiconductor devices to directly convert mechanical or thermal energy into electricity without moving parts, offering higher efficiency and durability. The solid-state design reduces maintenance needs and improves response time, but traditional generators remain preferable for high power output in heavy industrial applications.

Table of Comparison

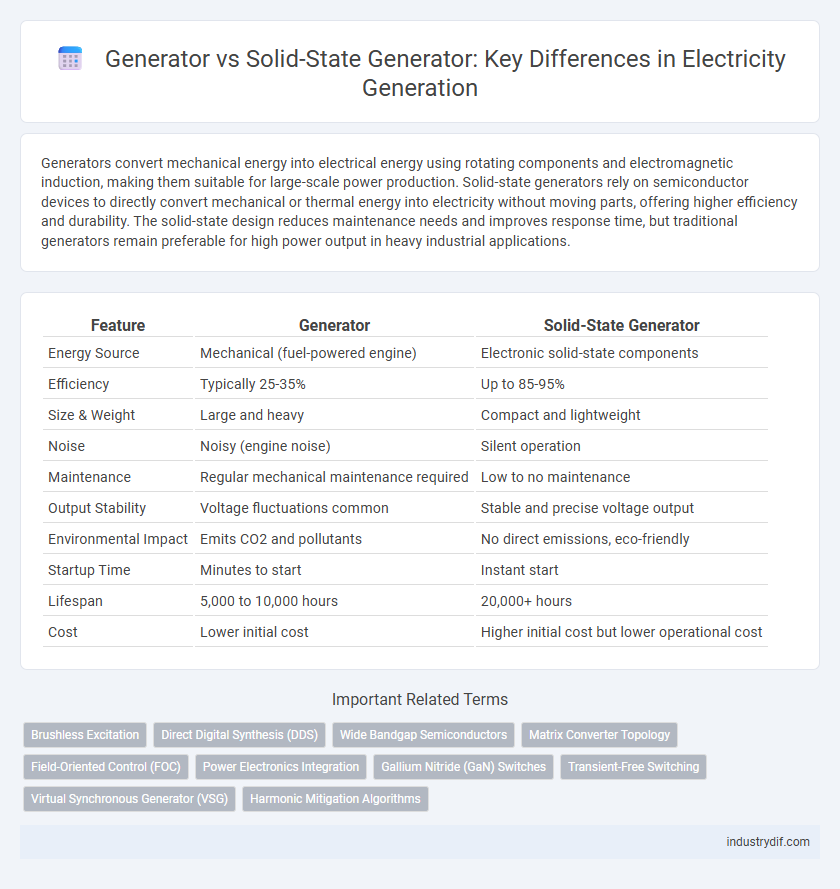

| Feature | Generator | Solid-State Generator |

|---|---|---|

| Energy Source | Mechanical (fuel-powered engine) | Electronic solid-state components |

| Efficiency | Typically 25-35% | Up to 85-95% |

| Size & Weight | Large and heavy | Compact and lightweight |

| Noise | Noisy (engine noise) | Silent operation |

| Maintenance | Regular mechanical maintenance required | Low to no maintenance |

| Output Stability | Voltage fluctuations common | Stable and precise voltage output |

| Environmental Impact | Emits CO2 and pollutants | No direct emissions, eco-friendly |

| Startup Time | Minutes to start | Instant start |

| Lifespan | 5,000 to 10,000 hours | 20,000+ hours |

| Cost | Lower initial cost | Higher initial cost but lower operational cost |

Introduction to Generators in the Electricity Industry

Generators convert mechanical energy into electrical energy, serving as critical components in power plants and grid systems. Traditional generators utilize electromagnetic induction with rotating coils and magnets to produce alternating current (AC). Solid-state generators, leveraging semiconductor technology, provide enhanced efficiency, compactness, and faster response times, revolutionizing electricity production and distribution.

What is a Conventional Generator?

A conventional generator converts mechanical energy into electrical energy using electromagnetic induction with rotating coils and a magnetic field. It typically consists of a rotor, stator, and slip rings or brushes to transfer electricity. Unlike solid-state generators that rely on semiconductor technology, conventional generators use mechanical parts, making them robust but subject to wear and maintenance.

Understanding Solid-State Generators

Solid-state generators convert mechanical energy into electrical energy using semiconductor components rather than traditional rotating parts, resulting in increased efficiency and reduced maintenance. Unlike conventional generators that rely on electromagnetic induction and moving coils, solid-state generators utilize power electronics and advanced materials to produce stable and precise electrical output. This technology enhances energy conversion reliability and supports integration with renewable energy systems and smart grids.

Working Principles: Generator vs Solid-State Generator

Traditional generators convert mechanical energy into electrical energy through electromagnetic induction, where a rotating coil within a magnetic field induces an electric current. Solid-state generators rely on semiconductor materials and electronic circuits to produce electricity by manipulating charge carriers without moving parts. The absence of mechanical motion in solid-state generators results in higher efficiency, reduced wear, and faster response times compared to conventional electromagnetic generators.

Efficiency Comparison

Traditional generators convert mechanical energy into electrical energy through electromagnetic induction, typically achieving efficiency rates between 85% and 95%. Solid-state generators utilize semiconductor materials to directly convert mechanical or thermal energy into electricity with fewer moving parts, often reaching efficiency levels exceeding 90%, especially in low-power applications. The higher energy conversion efficiency, reduced mechanical wear, and minimal maintenance requirements position solid-state generators as superior alternatives in settings demanding compactness and reliability.

Reliability and Maintenance Needs

Generators with mechanical components typically require frequent maintenance to ensure reliability, including regular oil changes and parts replacement. Solid-state generators, employing advanced power electronics, offer higher reliability by eliminating moving parts, significantly reducing maintenance demands and downtime. Their robust design enhances operational stability, making them ideal for critical applications where consistent power supply is essential.

Applications in Modern Electrical Systems

Generators are essential in modern electrical systems for converting mechanical energy into electrical power, supporting applications like backup power supply and grid stabilization. Solid-state generators, leveraging power electronics and semiconductor devices, offer advantages in renewable energy integration, electric vehicles, and microgrid technologies due to their compact size, higher efficiency, and faster response times. The shift toward smart grids and distributed energy resources emphasizes the growing role of solid-state generators in enhancing energy reliability and enabling seamless power management.

Environmental Impact Assessment

Traditional generators rely on fossil fuels, emitting significant greenhouse gases and contributing to air pollution, whereas solid-state generators offer a cleaner alternative by using semiconductor technology with minimal emissions. Solid-state generators reduce noise pollution and have a smaller carbon footprint due to higher efficiency and fewer moving parts. Environmental Impact Assessments highlight that adopting solid-state generators can substantially lower environmental degradation associated with electricity production.

Cost Analysis and Long-term Investment

A traditional generator typically involves higher initial costs and ongoing maintenance expenses due to mechanical wear and fuel consumption, making it less cost-effective over time. Solid-state generators offer lower operational costs and improved efficiency, reducing long-term investment risks through minimal maintenance and enhanced durability. Evaluating total cost of ownership highlights solid-state technology as a more economical and sustainable choice for extended power generation.

Future Trends in Generator Technologies

Future trends in generator technologies emphasize the shift towards solid-state generators, which offer higher efficiency, reduced maintenance, and compact design compared to traditional mechanical generators. Advancements in power electronics and semiconductor materials are enabling solid-state generators to deliver cleaner energy with improved reliability and faster response times. Integration with smart grids and renewable energy sources is driving the adoption of solid-state generator systems for sustainable and flexible electricity generation.

Related Important Terms

Brushless Excitation

Brushless excitation systems in generators eliminate the need for brushes and slip rings, reducing maintenance requirements and enhancing reliability compared to traditional solid-state generators. This technology improves voltage regulation and operational efficiency by using a rotating rectifier assembly to supply DC excitation without direct electrical contact.

Direct Digital Synthesis (DDS)

Direct Digital Synthesis (DDS) technology in solid-state generators enables precise frequency control, rapid waveform adjustments, and superior signal purity compared to traditional electromechanical generators. This results in enhanced efficiency, reduced signal distortion, and improved reliability for advanced electrical applications.

Wide Bandgap Semiconductors

Wide bandgap semiconductors enable solid-state generators to operate at higher voltages, temperatures, and frequencies compared to traditional electromagnetic generators, resulting in improved efficiency and reduced size. These advanced materials, such as silicon carbide (SiC) and gallium nitride (GaN), significantly enhance power density and thermal management in modern electricity generation systems.

Matrix Converter Topology

Matrix converter topology in solid-state generators offers direct AC-AC power conversion without intermediate DC stages, enhancing efficiency and reducing size compared to traditional mechanical generators. This topology enables precise output frequency and voltage control, making solid-state generators ideal for compact, high-performance electrical systems.

Field-Oriented Control (FOC)

Field-Oriented Control (FOC) significantly enhances the performance of both traditional generators and solid-state generators by enabling precise regulation of electromagnetic torque and flux, resulting in higher efficiency and reduced mechanical stress. Solid-state generators leverage FOC to optimize power conversion and dynamic response, offering superior control over conventional mechanical generators in renewable energy and electric vehicle applications.

Power Electronics Integration

Power electronics integration in traditional generators relies on mechanical energy conversion, whereas solid-state generators utilize semiconductor devices to directly convert mechanical or other forms of energy into electrical power with higher efficiency and faster response times. Solid-state generators enable precise control of output voltage and frequency through advanced power semiconductor components like IGBTs and MOSFETs, reducing losses and improving overall system reliability compared to conventional rotating machinery.

Gallium Nitride (GaN) Switches

Gallium Nitride (GaN) switches in solid-state generators enable higher efficiency, faster switching speeds, and greater thermal performance compared to traditional mechanical generators, significantly reducing energy losses and enhancing power density. These advanced GaN-based converters support compact, reliable electricity generation systems ideal for renewable and grid applications, surpassing conventional generator limitations.

Transient-Free Switching

Solid-state generators utilize semiconductor devices for transient-free switching, enabling rapid and precise control of electrical output without voltage spikes or current surges common in conventional generators. This advanced switching technology enhances system stability and reduces electromagnetic interference, making solid-state generators ideal for sensitive electronic applications and renewable energy integration.

Virtual Synchronous Generator (VSG)

Virtual Synchronous Generators (VSG) enhance grid stability by emulating the inertia and response characteristics of traditional synchronous generators through advanced power electronics and control algorithms. Unlike conventional generators, VSGs provide faster fault ride-through, improved frequency regulation, and seamless integration with renewable energy sources, making them critical for modern decentralized power systems.

Harmonic Mitigation Algorithms

Harmonic mitigation algorithms in solid-state generators significantly reduce waveform distortion by dynamically filtering and compensating for harmonic frequencies, unlike traditional generators that often produce higher harmonic content due to mechanical and electromagnetic inconsistencies. These algorithms improve power quality, enhance grid stability, and increase the efficiency of electrical systems in applications ranging from industrial motors to renewable energy integration.

Generator vs Solid-state generator Infographic

industrydif.com

industrydif.com