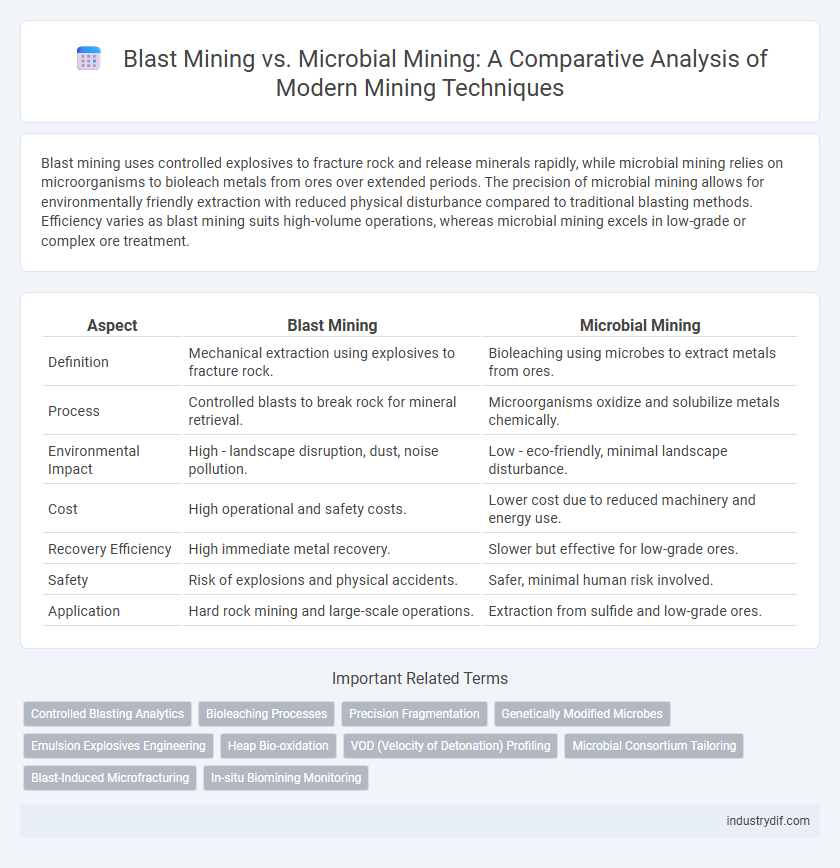

Blast mining uses controlled explosives to fracture rock and release minerals rapidly, while microbial mining relies on microorganisms to bioleach metals from ores over extended periods. The precision of microbial mining allows for environmentally friendly extraction with reduced physical disturbance compared to traditional blasting methods. Efficiency varies as blast mining suits high-volume operations, whereas microbial mining excels in low-grade or complex ore treatment.

Table of Comparison

| Aspect | Blast Mining | Microbial Mining |

|---|---|---|

| Definition | Mechanical extraction using explosives to fracture rock. | Bioleaching using microbes to extract metals from ores. |

| Process | Controlled blasts to break rock for mineral retrieval. | Microorganisms oxidize and solubilize metals chemically. |

| Environmental Impact | High - landscape disruption, dust, noise pollution. | Low - eco-friendly, minimal landscape disturbance. |

| Cost | High operational and safety costs. | Lower cost due to reduced machinery and energy use. |

| Recovery Efficiency | High immediate metal recovery. | Slower but effective for low-grade ores. |

| Safety | Risk of explosions and physical accidents. | Safer, minimal human risk involved. |

| Application | Hard rock mining and large-scale operations. | Extraction from sulfide and low-grade ores. |

Introduction to Blast Mining and Microbial Mining

Blast mining utilizes controlled explosive charges to fracture rock and extract minerals with high efficiency in large-scale operations. Microbial mining, also known as bioleaching, employs specific microorganisms to biologically oxidize and dissolve valuable metals from ores, enabling eco-friendly extraction in low-grade deposits. Both methods optimize mineral recovery but differ significantly in scalability, environmental impact, and operational mechanisms.

Fundamental Principles of Blast Mining

Blast mining relies on controlled explosive detonation to fracture rock, enabling efficient extraction of valuable minerals from blast holes strategically drilled in ore bodies. The fundamental principles involve precise calculation of charge size, timing, and placement to maximize rock fragmentation while minimizing ground vibrations and environmental impact. This energy-intensive technique contrasts with microbial mining, which utilizes specific microorganisms to bioleach metals in a slower, more environmentally friendly process.

Overview of Microbial Mining Techniques

Microbial mining techniques utilize specific microorganisms to extract metals from ores through bioleaching and biomining processes, offering an environmentally friendly alternative to traditional blast mining. These methods involve the oxidation of sulfide minerals by bacteria such as Acidithiobacillus ferrooxidans, enabling efficient recovery of metals like copper, gold, and uranium from low-grade ores. Compared to blast mining, microbial mining reduces environmental impact, lowers energy consumption, and enhances metal recovery rates in complex ore bodies.

Resource Efficiency: Blast vs Microbial Mining

Blast mining rapidly extracts large volumes of ore but often results in significant resource loss and environmental degradation due to its imprecise nature. Microbial mining enhances resource efficiency by selectively targeting metal ores through bioleaching processes, minimizing waste and reducing energy consumption. The bio-based approach optimizes metal recovery rates and promotes sustainable mining practices by lowering the ecological footprint compared to conventional blasting methods.

Environmental Impact Comparison

Blast mining generates significant environmental damage, including air and noise pollution, habitat destruction, and large amounts of mining waste. Microbial mining offers a more sustainable alternative by utilizing natural microorganisms to extract metals, resulting in lower energy consumption and minimal toxic byproducts. This biotechnological approach significantly reduces soil and water contamination, promoting better ecosystem preservation compared to traditional blast mining methods.

Operational Safety and Risk Factors

Blast mining involves controlled explosions to fragment rock, posing significant risks such as ground vibrations, flying debris, and toxic gas emissions, which demand stringent safety protocols and protective equipment. Microbial mining employs microorganisms to extract metals, greatly reducing physical hazards and environmental impact but requires strict monitoring of microbial activity to prevent unintended biohazard risks. Both methods require tailored operational safety measures, with blast mining emphasizing physical risk management and microbial mining focusing on biological containment and environmental control.

Cost Analysis: Initial and Ongoing Expenses

Blast mining requires significant initial investment in explosives, heavy machinery, and safety infrastructure, leading to high upfront costs. Ongoing expenses include maintenance of equipment, labor, and environmental management, often resulting in fluctuating operational costs. In contrast, microbial mining involves lower initial expenses due to minimal machinery needs but may incur prolonged ongoing costs from culture maintenance, nutrient supply, and slower extraction rates impacting overall financial efficiency.

Ore Recovery Efficiency and Yield Rates

Blast mining offers rapid ore recovery with yield rates typically ranging from 70% to 85%, but it generates significant waste and environmental disruption. Microbial mining, or bioleaching, improves ore recovery efficiency by selectively extracting metals from low-grade ores with yield rates between 60% and 90%, depending on microbial activity and ore composition. Optimization of microbial consortia and process parameters can enhance yield rates, making microbial mining a more sustainable choice with higher purity outputs compared to blast mining.

Applications and Suitability for Different Minerals

Blast mining is primarily applied in extracting hard minerals like coal, iron ore, and limestone due to its efficiency in breaking large rock masses quickly. Microbial mining, or bioleaching, targets metals such as copper, gold, and uranium by utilizing bacteria to dissolve and extract metals from low-grade ores and waste materials, making it suitable for environmentally sensitive operations. The choice between blast mining and microbial mining depends on ore type, environmental impact considerations, and economic viability for specific mineral deposits.

Future Trends in Mining: Innovations and Sustainability

Blast mining, a traditional extraction method, faces growing challenges due to environmental concerns and increasing regulatory restrictions, prompting a shift toward more sustainable approaches like microbial mining. Microbial mining utilizes bacteria and archaea to bioleach metals from ores, offering enhanced efficiency, reduced energy consumption, and lower ecological impact, aligning with future trends prioritizing green technologies. Innovations in microbial mining are expected to drive sustainable resource recovery, minimize environmental footprint, and support circular economy models in the evolving mining industry.

Related Important Terms

Controlled Blasting Analytics

Blast mining utilizes controlled blasting analytics to enhance fragmentation precision, improve safety, and optimize explosive energy distribution. Microbial mining, conversely, leverages bioleaching techniques without traditional blasting, emphasizing chemical kinetics and microbial metabolism over controlled fragmentation.

Bioleaching Processes

Blast mining relies on controlled explosives to fragment ore for extraction, while microbial mining utilizes bioleaching processes where specific bacteria, such as Acidithiobacillus ferrooxidans, oxidize sulfide minerals to solubilize metals like copper and gold. Bioleaching offers an environmentally sustainable alternative by reducing the need for harsh chemicals and energy-intensive blasting, enhancing metal recovery in low-grade ores through biochemical reactions.

Precision Fragmentation

Blast mining achieves precision fragmentation through controlled explosives that break rock into manageable sizes, optimizing ore extraction efficiency. In contrast, microbial mining offers ultra-precise fragmentation by leveraging biological processes to selectively dissolve ore minerals, minimizing waste and reducing environmental impact.

Genetically Modified Microbes

Genetically modified microbes in microbial mining enhance metal extraction efficiency by breaking down ores at a molecular level, reducing environmental impact compared to traditional blast mining methods that rely on explosives and cause significant ecological disruption. Advances in genetic engineering enable the development of microbes tailored to extract specific metals such as copper, gold, and uranium, offering a sustainable and cost-effective alternative to blasting techniques.

Emulsion Explosives Engineering

Emulsion explosives engineering enhances blast mining efficiency by providing controlled energy release and improved safety through water resistance and high detonation velocity. Microbial mining, although environmentally friendly, lacks the rapid fragmentation capabilities of emulsion explosives used in blast mining, making it less suitable for large-scale ore extraction.

Heap Bio-oxidation

Blast mining employs controlled explosives to fracture ore deposits, enabling efficient extraction of minerals, while microbial mining utilizes bio-oxidation by specialized microorganisms to break down sulfide ores in heaps, enhancing metal recovery. Heap bio-oxidation is a cost-effective microbial mining technique where bacteria such as Acidithiobacillus ferrooxidans oxidize sulfide minerals, facilitating gold extraction from refractory ores.

VOD (Velocity of Detonation) Profiling

Blast mining relies heavily on precise VOD (Velocity of Detonation) profiling to optimize explosive energy distribution and fragment rock efficiently, enhancing overall productivity. In contrast, microbial mining bypasses traditional explosive methods, rendering VOD profiling irrelevant while emphasizing bioleaching kinetics and microbial activity rates to improve mineral extraction.

Microbial Consortium Tailoring

Microbial consortium tailoring in microbial mining enhances metal recovery by optimizing synergistic interactions between diverse microbial species for efficient bioleaching of ores, contrasting with blast mining's reliance on explosives for mineral extraction. This biotechnological approach reduces environmental impact and operational costs while improving selectivity and extraction rates in mining processes.

Blast-Induced Microfracturing

Blast-induced microfracturing enhances rock fragmentation by generating a network of microcracks that improve permeability and ore recoverability in blast mining operations. Unlike microbial mining, which relies on biochemical processes to extract metals, blast mining's microfracturing accelerates physical disintegration, optimizing subsequent mineral processing efficiency.

In-situ Biomining Monitoring

Blast mining involves explosive techniques to fragment rock for mineral extraction, generating significant environmental disturbance and requiring extensive safety protocols. In contrast, microbial mining utilizes microorganisms to leach metals directly from ores in situ, with monitoring centered on bioactivity, metal solubilization rates, and environmental parameters to optimize recovery and minimize ecological impact.

Blast mining vs Microbial mining Infographic

industrydif.com

industrydif.com