Surface mining involves the excavation of large open pits to extract minerals close to the earth's surface, offering high productivity and cost efficiency for shallow deposits. Autonomous haulage mining utilizes driverless vehicles to transport extracted material, enhancing safety, reducing labor costs, and increasing operational efficiency in both surface and underground mining environments. The integration of autonomous haulage systems in surface mining optimizes haul cycles, improves fuel consumption, and minimizes environmental impact through precise fleet management.

Table of Comparison

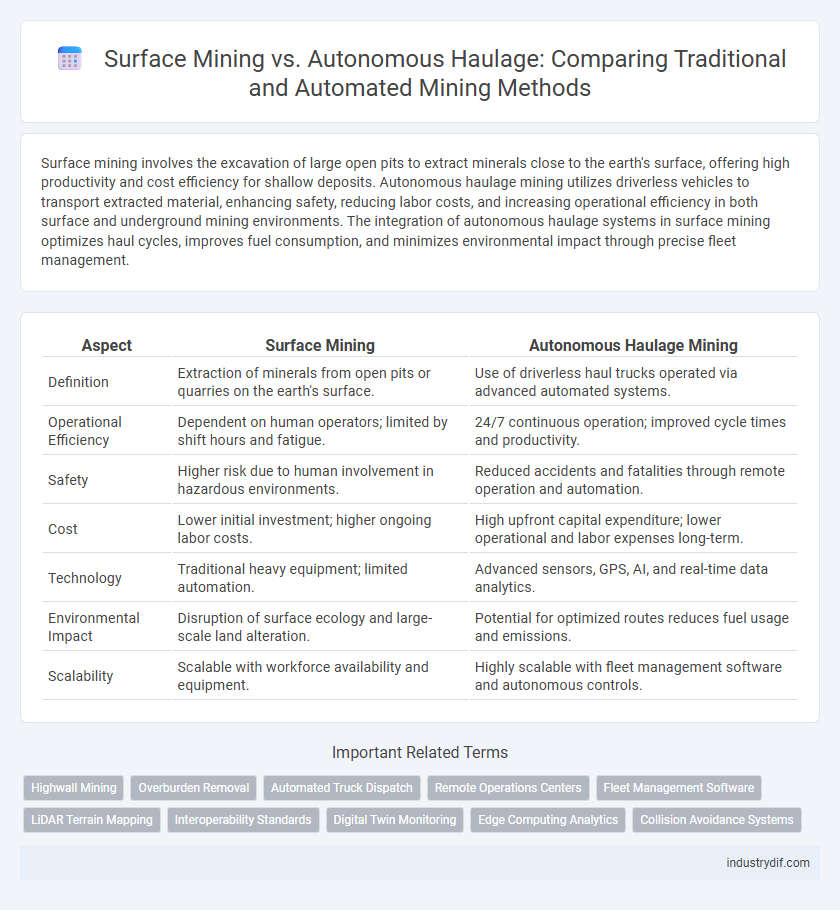

| Aspect | Surface Mining | Autonomous Haulage Mining |

|---|---|---|

| Definition | Extraction of minerals from open pits or quarries on the earth's surface. | Use of driverless haul trucks operated via advanced automated systems. |

| Operational Efficiency | Dependent on human operators; limited by shift hours and fatigue. | 24/7 continuous operation; improved cycle times and productivity. |

| Safety | Higher risk due to human involvement in hazardous environments. | Reduced accidents and fatalities through remote operation and automation. |

| Cost | Lower initial investment; higher ongoing labor costs. | High upfront capital expenditure; lower operational and labor expenses long-term. |

| Technology | Traditional heavy equipment; limited automation. | Advanced sensors, GPS, AI, and real-time data analytics. |

| Environmental Impact | Disruption of surface ecology and large-scale land alteration. | Potential for optimized routes reduces fuel usage and emissions. |

| Scalability | Scalable with workforce availability and equipment. | Highly scalable with fleet management software and autonomous controls. |

Overview of Surface Mining Techniques

Surface mining techniques include open-pit mining, strip mining, and quarrying, each designed to extract minerals from the earth's surface efficiently. Autonomous haulage mining utilizes driverless trucks equipped with advanced GPS and sensor technologies, significantly enhancing operational safety and productivity. Integration of autonomous haulage systems with traditional surface mining methods optimizes ore transport, reduces labor costs, and minimizes environmental impact.

Introduction to Autonomous Haulage Systems

Autonomous Haulage Systems (AHS) revolutionize surface mining by automating the transportation of materials using driverless trucks equipped with advanced sensors and GPS technology. These systems enhance operational efficiency, reduce human error, and improve safety by enabling continuous, precise haulage in challenging mining environments. Integration of AHS with real-time data analytics optimizes fleet management and minimizes downtime compared to traditional surface mining haulage methods.

Key Differences Between Traditional and Autonomous Haulage

Surface mining relies on human-operated trucks and equipment for material extraction and transportation, limiting operational hours and increasing labor costs. Autonomous haulage systems use driverless trucks equipped with advanced GPS, sensors, and AI technology, enhancing safety, efficiency, and continuous operation. Key differences include reduced human error, lower operational costs, and improved production rates in autonomous haulage compared to traditional surface mining methods.

Safety Enhancements in Autonomous Haulage Mining

Autonomous haulage mining significantly improves safety by reducing human exposure to hazardous environments and minimizing the risk of accidents caused by operator error. Advanced sensors and real-time monitoring systems enable autonomous vehicles to detect obstacles and adjust routes, enhancing operational safety. Surface mining operations integrating autonomous haulage experience fewer incidents and lower fatality rates compared to traditional surface mining methods.

Efficiency and Productivity Comparisons

Surface mining achieves high productivity through large-scale equipment and open-pit designs, enabling rapid extraction of near-surface minerals. Autonomous haulage mining enhances efficiency by utilizing driverless trucks equipped with GPS and advanced sensors, reducing human error and enabling continuous operation with optimized routes. Compared to traditional surface mining, autonomous haulage systems significantly decrease operational costs and increase cycle times, resulting in higher overall efficiency and improved resource recovery rates.

Environmental Impact: Surface Mining vs Autonomous Technology

Surface mining generates significant environmental disruption through large-scale land disturbance, habitat destruction, and increased dust and noise pollution. Autonomous haulage systems in mining reduce emissions and energy consumption by optimizing vehicle routes and speeds, leading to lower carbon footprints and minimizing ecological damage. Implementation of autonomous technology also enhances operational safety and reduces the need for extensive land clearing, contributing to more sustainable mining practices.

Initial Investment and Operating Costs

Surface mining requires a substantial initial investment in heavy machinery and land preparation, whereas autonomous haulage systems demand high upfront costs for advanced technology and integration. Operating costs for surface mining include fuel, labor, and maintenance, while autonomous haulage reduces labor expenses but incurs ongoing expenses for software, sensors, and system monitoring. Overall, autonomous haulage mining offers potential cost savings over time through enhanced efficiency and reduced human resource requirements despite higher initial technology investments.

Workforce Implications and Skill Requirements

Surface mining demands a workforce skilled in operating heavy machinery and performing manual inspections, emphasizing physical labor and technical maintenance knowledge. Autonomous haulage mining shifts the skill requirements towards advanced technological competencies, such as programming, system monitoring, and data analysis, reducing the need for on-site operators. This transition impacts workforce size and training programs, necessitating upskilling and reskilling initiatives to manage automated equipment and ensure operational safety and efficiency.

Case Studies: Successful Adoption of Autonomous Haulage

Case studies of autonomous haulage systems in surface mining demonstrate significant improvements in safety, productivity, and cost efficiency. Companies like Rio Tinto and BHP have reported up to 30% increase in haulage efficiency and a 50% reduction in operational costs by integrating autonomous trucks. These successful adoptions highlight how autonomous haulage mining can optimize ore transport and reduce human error in large-scale surface mining operations.

Future Trends in Surface and Autonomous Haulage Mining

Future trends in surface mining emphasize increased adoption of autonomous haulage systems to enhance operational efficiency, safety, and cost reduction. Integration of AI-driven fleet management and real-time data analytics is transforming autonomous haulage, enabling predictive maintenance and optimized haul routes. Advancements in electric and hybrid haul trucks further align with sustainable mining practices, reducing carbon footprints in surface mining operations.

Related Important Terms

Highwall Mining

Highwall mining, a form of surface mining, utilizes continuous miners to extract coal from exposed seams along the highwall, offering a cost-effective alternative to traditional open-pit methods. Autonomous haulage mining enhances productivity and safety by deploying driverless trucks to transport materials from highwall mining operations, reducing labor costs and minimizing human exposure to hazardous environments.

Overburden Removal

Surface mining relies on traditional haul trucks operated by humans for overburden removal, often resulting in higher operational costs and safety risks. Autonomous haulage systems enhance efficiency and safety by using driverless trucks controlled through advanced automated technologies, significantly optimizing overburden removal in large-scale mining operations.

Automated Truck Dispatch

Automated truck dispatch in surface mining significantly enhances operational efficiency by utilizing real-time data analytics and GPS tracking to optimize haulage routes and reduce idle times. Compared to traditional autonomous haulage mining systems, automated dispatch integrates seamlessly with existing fleet management software, enabling dynamic task allocation and improved resource utilization.

Remote Operations Centers

Surface mining increasingly integrates Autonomous Haulage Systems (AHS) managed from Remote Operations Centers (ROCs), enhancing operational efficiency, safety, and real-time data analytics. ROCs leverage advanced communication networks and AI to remotely control and monitor autonomous haul trucks, reducing onsite personnel and optimizing ore extraction processes.

Fleet Management Software

Surface mining benefits from fleet management software by optimizing truck routes, reducing fuel consumption, and improving equipment utilization, leading to increased operational efficiency. In autonomous haulage mining, advanced fleet management systems enable real-time monitoring, predictive maintenance, and seamless coordination of driverless vehicles, significantly enhancing safety and productivity.

LiDAR Terrain Mapping

Surface mining employs traditional excavation techniques with limited real-time terrain data, whereas autonomous haulage mining leverages advanced LiDAR terrain mapping to create precise 3D models for optimized route planning and increased operational safety. LiDAR technology enhances autonomous haulage systems by providing continuous, high-resolution topographical data, enabling efficient navigation and dynamic hazard detection in complex surface mining environments.

Interoperability Standards

Interoperability standards in surface mining enable seamless integration of diverse equipment and systems, enhancing operational efficiency and data exchange. Autonomous haulage mining relies heavily on standardized communication protocols such as ISO/IEC 21815 to ensure compatibility between autonomous vehicles and control systems, reducing downtime and improving safety.

Digital Twin Monitoring

Surface mining leverages digital twin monitoring to create real-time, data-driven simulations of mine sites, enhancing operational efficiency and predictive maintenance. Autonomous haulage mining integrates these digital twins with AI-driven vehicle control systems, optimizing haul routes and reducing downtime through continuous performance analysis.

Edge Computing Analytics

Surface mining increasingly integrates edge computing analytics to process real-time operational data on-site, enhancing equipment efficiency and predictive maintenance. Autonomous haulage systems leverage edge analytics to optimize vehicle routing and safety by analyzing sensor data locally, reducing latency and reliance on centralized cloud infrastructure.

Collision Avoidance Systems

Surface mining operations utilizing Autonomous Haulage Systems (AHS) integrate advanced Collision Avoidance Systems (CAS) equipped with LiDAR, radar, and real-time data processing to enhance safety and operational efficiency. These systems significantly reduce collision risks by enabling autonomous trucks to detect and respond to obstacles dynamically, outperforming traditional manned surface mining vehicles reliant on human operators.

Surface mining vs Autonomous haulage mining Infographic

industrydif.com

industrydif.com