Conventional flotation relies on larger bubbles to separate valuable minerals from ore, often resulting in lower recovery rates and higher reagent consumption. Microbubble flotation introduces ultra-fine bubbles that increase the surface area, enhancing mineral-bubble attachment and improving recovery efficiency. This advanced technique reduces energy usage and reagent costs while maximizing the extraction of fine and ultrafine particles.

Table of Comparison

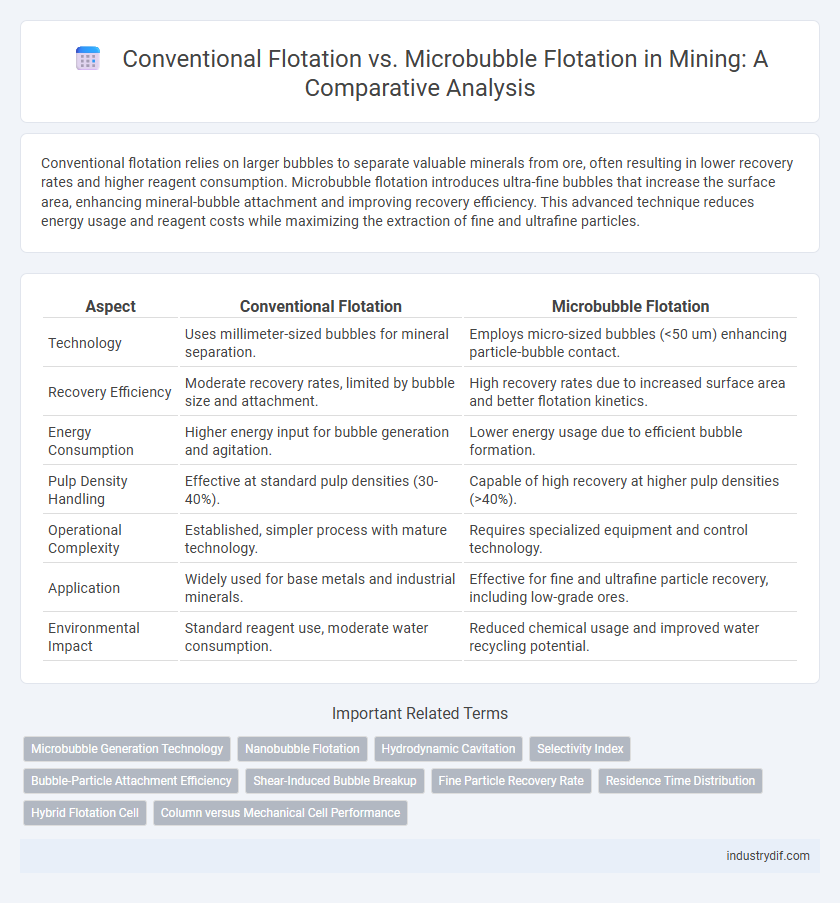

| Aspect | Conventional Flotation | Microbubble Flotation |

|---|---|---|

| Technology | Uses millimeter-sized bubbles for mineral separation. | Employs micro-sized bubbles (<50 um) enhancing particle-bubble contact. |

| Recovery Efficiency | Moderate recovery rates, limited by bubble size and attachment. | High recovery rates due to increased surface area and better flotation kinetics. |

| Energy Consumption | Higher energy input for bubble generation and agitation. | Lower energy usage due to efficient bubble formation. |

| Pulp Density Handling | Effective at standard pulp densities (30-40%). | Capable of high recovery at higher pulp densities (>40%). |

| Operational Complexity | Established, simpler process with mature technology. | Requires specialized equipment and control technology. |

| Application | Widely used for base metals and industrial minerals. | Effective for fine and ultrafine particle recovery, including low-grade ores. |

| Environmental Impact | Standard reagent use, moderate water consumption. | Reduced chemical usage and improved water recycling potential. |

Introduction to Flotation Techniques in Mining

Conventional flotation separates valuable minerals from ore using air bubbles typically larger than 100 micrometers, relying on hydrophobic properties to attach particles to bubbles. Microbubble flotation employs significantly smaller bubbles, usually less than 50 micrometers, enhancing particle-bubble collision efficiency and recovery rates of fine or low-grade minerals. This technique maximizes surface area contact, improves recovery of ultrafine particles, and reduces chemical consumption compared to traditional flotation methods.

Fundamentals of Conventional Flotation

Conventional flotation relies on the attachment of hydrophobic mineral particles to air bubbles generated by impellers in a flotation cell, enabling their separation from hydrophilic gangue. The process hinges on factors such as bubble size, pulp chemistry, and reagent dosage to optimize particle-bubble collision and adhesion. Key parameters include bubble-particle attachment efficiency, froth stability, and collector selectivity, which collectively influence mineral recovery and concentrate grade.

Principles of Microbubble Flotation Technology

Microbubble flotation technology leverages micro-scale gas bubbles, typically less than 50 micrometers in diameter, to enhance the attachment efficiency of fine mineral particles compared to conventional flotation. The increased surface area and slower rise velocity of microbubbles improve particle-bubble collision and adhesion, resulting in higher recovery rates and selectivity in mineral separation. This principle allows for more effective liberation of valuable minerals from ores, especially in fine and complex mineral matrices, optimizing overall flotation performance.

Particle-Bubble Interaction Mechanisms

Conventional flotation relies on larger bubbles to attach hydrophobic particles through collision and adhesion, whereas microbubble flotation enhances particle-bubble interactions by increasing bubble surface area and reducing bubble size, resulting in higher collision efficiency. Microbubbles generate stronger capillary forces and promote greater particle entrainment due to their higher surface-to-volume ratio and prolonged bubble-particle contact time. This leads to improved recovery rates and selectivity in mineral separation processes compared to traditional flotation methods.

Equipment Design: Conventional vs. Microbubble Flotation Cells

Conventional flotation cells rely on mechanical agitation and coarse air bubbles to separate minerals, often requiring larger equipment and higher energy consumption. Microbubble flotation cells utilize advanced microbubble generation technology that produces finer bubbles, enhancing mineral attachment efficiency and allowing for more compact, energy-efficient designs. The improved bubble-particle interactions in microbubble cells lead to increased recovery rates and reduced operating costs compared to traditional flotation systems.

Efficiency and Recovery Rates Comparison

Microbubble flotation enhances mineral recovery rates by generating smaller bubbles that improve particle-bubble attachment and increase surface area interaction, leading to higher efficiency than conventional flotation. Conventional flotation typically recovers 85-90% of target minerals, while microbubble flotation can achieve recovery improvements of up to 10%, particularly in fine particle processing. The increased flotation efficiency of microbubble technology reduces reagent consumption and energy costs, making it a more sustainable option for improved mineral extraction.

Energy Consumption and Operational Costs

Conventional flotation systems typically consume higher energy due to larger air compressors and agitators, resulting in elevated operational costs, while microbubble flotation significantly reduces energy usage by generating finer bubbles with minimal power input. Microbubble flotation enhances particle recovery rates and decreases reagent dosage, leading to lower overall processing expenses. The improved efficiency and reduced equipment stress in microbubble technology contribute to sustainable mining practices through cost-effective mineral separation.

Application Suitability for Different Ores

Conventional flotation suits coarse and moderately fine ores with larger particles, efficiently separating sulfide minerals in copper and zinc processing. Microbubble flotation excels in ultra-fine particle recovery and low-grade ores, enhancing the capture of finely disseminated minerals in complex polymetallic deposits. Both methods integrate effectively depending on ore mineralogy, particle size distribution, and target recovery rates in gold, nickel, and phosphate mining operations.

Environmental Impact and Water Management

Conventional flotation generates larger volumes of tailings and consumes more water, leading to increased environmental strain and higher risks of water contamination. Microbubble flotation significantly reduces water usage by enhancing particle recovery efficiency, resulting in lower tailings volume and minimized chemical reagent consumption. Improved water recycling and reduced discharge from microbubble flotation offer sustainable water management solutions and mitigate environmental impact in mining operations.

Future Trends in Flotation Technology

Future trends in flotation technology emphasize the integration of microbubble flotation to enhance mineral recovery rates and reduce chemical reagent usage compared to conventional flotation methods. Advances in microbubble generation techniques, such as employing nanobubble technology and improved flotation cell designs, contribute to higher selectivity and energy efficiency. Research continues to focus on real-time process monitoring and automation to optimize flotation performance in complex ore processing.

Related Important Terms

Microbubble Generation Technology

Microbubble generation technology in flotation enhances mineral recovery by producing ultrafine bubbles that increase particle-bubble collision efficiency, resulting in higher selectivity and improved separation compared to conventional flotation. This advanced method utilizes nanobubble cavitation and gas dissolution techniques to create stable microbubbles, boosting flotation kinetics and reducing reagent consumption in mining operations.

Nanobubble Flotation

Nanobubble flotation enhances mineral recovery by generating stable nanobubbles that improve particle-bubble attachment efficiency compared to conventional flotation and microbubble flotation. This advanced technique increases flotation rate and selectivity through superior bubble surface area and prolonged bubble lifetime, resulting in higher concentrate grade and recovery.

Hydrodynamic Cavitation

Hydrodynamic cavitation enhances microbubble flotation by generating finer bubbles with greater surface area, significantly improving the recovery rate of valuable minerals compared to conventional flotation methods. This technique increases mineral-bubble collision efficiency and reduces reagent consumption, optimizing the overall flotation process in mining operations.

Selectivity Index

Microbubble flotation demonstrates a significantly higher selectivity index compared to conventional flotation, enhancing mineral separation efficiency by targeting fine particles with greater precision. This improved selectivity reduces reagent consumption and increases recovery rates, optimizing the overall flotation process in mineral beneficiation.

Bubble-Particle Attachment Efficiency

Microbubble flotation significantly enhances bubble-particle attachment efficiency compared to conventional flotation by generating smaller bubbles that increase the surface area for particle collision and adhesion. This improvement leads to higher recovery rates of fine and hydrophobic mineral particles in mining operations.

Shear-Induced Bubble Breakup

Shear-induced bubble breakup significantly impacts the efficiency of flotation processes by reducing bubble size and increasing surface area, enhancing particle-bubble collision rates in microbubble flotation over conventional flotation. Microbubble flotation leverages finer bubbles generated through controlled shear forces, improving mineral recovery and selectivity in mining operations compared to traditional coarse bubble methods.

Fine Particle Recovery Rate

Conventional flotation typically achieves lower fine particle recovery rates, often below 50%, due to limited bubble-particle collision efficiency at small particle sizes. Microbubble flotation significantly enhances fine particle recovery by increasing bubble surface area and contact probability, frequently exceeding 70% recovery for particles under 20 microns.

Residence Time Distribution

Residence time distribution (RTD) in conventional flotation exhibits broader variability due to larger bubble sizes and slower mixing patterns, often resulting in less efficient particle-bubble interactions. In contrast, microbubble flotation achieves narrower RTD profiles with enhanced mass transfer rates and shorter residence times, promoting higher recovery rates and improved selectivity in mineral separations.

Hybrid Flotation Cell

Hybrid flotation cells combine conventional flotation techniques with microbubble technology to enhance mineral recovery and grade, offering improved gas dispersion and bubble-particle interactions. This integration increases recovery rates by up to 15% compared to traditional cells, optimizing processing efficiency in mineral beneficiation.

Column versus Mechanical Cell Performance

Column flotation demonstrates higher selectivity and recovery rates compared to mechanical cells by utilizing a stable froth layer and enhanced bubble-particle contact through microbubble generation. Mechanical cells, while offering higher throughput, often exhibit lower-grade concentrate due to coarser bubbles and turbulent mixing, making column flotation more effective for processing fine particles and complex ore matrices.

Conventional Flotation vs Microbubble Flotation Infographic

industrydif.com

industrydif.com