Underground mining involves extracting minerals through tunnels or shafts, allowing access to deep ore bodies with minimal surface disruption but higher operational costs and safety risks. In-situ recovery uses chemical solutions to dissolve minerals underground and pump them to the surface, offering a less invasive, cost-effective method primarily suited for soluble ores like uranium. Both methods require careful environmental management to prevent contamination and ensure sustainable resource extraction.

Table of Comparison

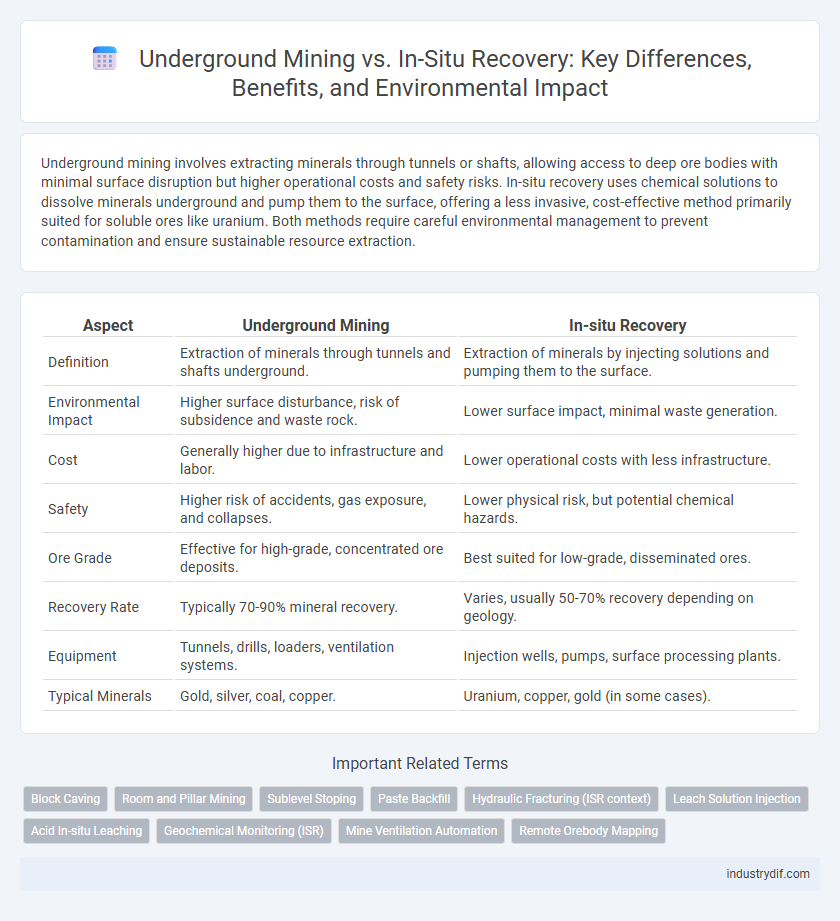

| Aspect | Underground Mining | In-situ Recovery |

|---|---|---|

| Definition | Extraction of minerals through tunnels and shafts underground. | Extraction of minerals by injecting solutions and pumping them to the surface. |

| Environmental Impact | Higher surface disturbance, risk of subsidence and waste rock. | Lower surface impact, minimal waste generation. |

| Cost | Generally higher due to infrastructure and labor. | Lower operational costs with less infrastructure. |

| Safety | Higher risk of accidents, gas exposure, and collapses. | Lower physical risk, but potential chemical hazards. |

| Ore Grade | Effective for high-grade, concentrated ore deposits. | Best suited for low-grade, disseminated ores. |

| Recovery Rate | Typically 70-90% mineral recovery. | Varies, usually 50-70% recovery depending on geology. |

| Equipment | Tunnels, drills, loaders, ventilation systems. | Injection wells, pumps, surface processing plants. |

| Typical Minerals | Gold, silver, coal, copper. | Uranium, copper, gold (in some cases). |

Overview of Underground Mining and In-Situ Recovery

Underground mining involves extracting minerals through tunnels or shafts beneath the surface, targeting deep ore bodies with minimal surface disturbance, and is suitable for high-grade deposits like gold and copper. In-situ recovery (ISR) uses chemical solutions injected into the ore body to dissolve minerals, which are then pumped to the surface, offering a cost-effective and environmentally friendly method primarily for uranium and copper deposits. Both methods differ significantly in operational complexity, environmental impact, and applicability based on ore location and geology.

Key Differences Between Extraction Methods

Underground mining involves creating tunnels to physically extract ore, enabling access to deep deposits with high-grade minerals but requiring extensive ventilation and safety measures. In-situ recovery (ISR) dissolves minerals directly in the deposit using chemical solutions, minimizing surface disturbance and reducing environmental impact but being limited to permeable ore bodies like uranium or copper. Key differences include operational complexity, environmental footprint, ore body suitability, and cost efficiency, making each method advantageous based on geological and economic factors.

Geological Suitability and Ore Types

Underground mining is best suited for high-grade, hard rock ores found in stable geological formations with significant vertical or steeply dipping ore bodies, such as gold, copper, and zinc deposits in metamorphic or igneous rocks. In-situ recovery (ISR) is optimal for permeable sedimentary formations containing soluble or leachable minerals like uranium and potash, where the ore exists as a dispersed solution or low-grade disseminated mineralization. Geological suitability for underground mining requires competent rock to support tunnels, while ISR depends on aquifer characteristics and hydrological conditions to enable efficient leachate circulation and mineral dissolution.

Environmental Impact Comparison

Underground mining typically causes significant land disturbance, habitat destruction, and groundwater contamination due to extensive excavation and waste rock handling. In contrast, in-situ recovery minimizes surface disruption and reduces waste production by extracting minerals directly from the ore body via chemical solutions injected underground. However, in-situ methods pose risks of aquifer contamination if leaching fluids migrate beyond the target zone, demanding rigorous monitoring and control measures.

Operational Costs and Economic Factors

Underground mining involves high operational costs due to extensive labor, ventilation, and safety requirements, making it capital-intensive. In-situ recovery offers lower economic risks with reduced capital expenditure and minimal surface disturbance, relying on fluid injection and extraction processes. Economic factors favor in-situ recovery in deposits with suitable permeability and geochemistry, whereas underground mining is preferred for high-grade ores where recovery efficiency justifies the higher costs.

Equipment and Technology Requirements

Underground mining requires heavy-duty equipment such as continuous miners, shuttle cars, and ventilation systems to manage deep excavation and worker safety, along with sophisticated ore extraction machinery. In-situ recovery relies on advanced fluid injection and extraction technology, including pumps and monitoring sensors, minimizing surface disturbance and drastically reducing the need for heavy machinery. The selection between these methods hinges on ore deposit characteristics and the technological capability to efficiently and safely process the resource.

Safety and Risk Management

Underground mining involves extensive tunneling and exposure to hazards such as rock falls, gas explosions, and poor ventilation, necessitating rigorous safety protocols and constant risk monitoring. In-situ recovery (ISR) minimizes physical exposure by extracting minerals through solution injection and recovery wells, significantly reducing occupational hazards and environmental disturbance. Effective risk management in underground mining emphasizes structural stability and air quality control, while ISR focuses on controlling solution containment and preventing groundwater contamination.

Resource Recovery Rates and Efficiency

Underground mining typically achieves resource recovery rates between 60-90%, depending on ore body characteristics and mining methods, while in-situ recovery (ISR) often attains 70-85% recovery by dissolving minerals directly in the deposit. ISR offers higher efficiency with lower operational costs, reduced environmental disturbance, and minimal ore dilution compared to traditional underground mining. Optimization of ISR processes through advanced leaching agents and monitoring technologies can further enhance extraction rates and overall resource utilization.

Case Studies: Global Examples

Case studies from global mining projects reveal distinct advantages of underground mining and in-situ recovery techniques. In South Africa, deep-level underground mining at the Mponeng Gold Mine demonstrates high ore extraction rates with controlled environmental impact, while Kazakhstan's Karachaganak field exemplifies efficient in-situ recovery of hydrocarbons with minimal surface disturbance. Comparative analyses emphasize site geology, ore type, and environmental regulations as critical factors in selecting the optimal mining method.

Future Trends and Innovations in Mining Methods

Underground mining continues to evolve with advancements in automation, robotics, and real-time monitoring systems, enhancing safety and operational efficiency in deep and complex ore bodies. In-situ recovery methods are gaining momentum due to their lower environmental footprint, utilizing innovative leaching techniques and sensor technologies for precise extraction of minerals without extensive surface disturbance. Future trends highlight the integration of digital twins and AI-driven analytics to optimize both underground mining and in-situ recovery processes, reducing costs and improving resource recovery rates.

Related Important Terms

Block Caving

Block caving is an underground mining method that involves the controlled collapse of rock to extract ore, offering high production rates and low operational costs compared to in-situ recovery, which dissolves minerals in place for extraction. While underground block caving enables access to massive ore bodies with substantial economies of scale, in-situ recovery minimizes surface disturbance and water usage but is limited to soluble minerals and specific geological conditions.

Room and Pillar Mining

Room and pillar mining involves excavating horizontal tunnels while leaving pillars of ore to support the roof, making it suitable for flat-lying ore deposits and ensuring stability during extraction. In contrast, in-situ recovery dissolves minerals directly in the ground and pumps the solution to the surface, minimizing surface disturbance but limiting applications to soluble ore bodies.

Sublevel Stoping

Sublevel stoping in underground mining involves creating horizontal levels within an ore body to extract minerals efficiently by drilling and blasting, offering high recovery rates and safety in stable rock conditions. In contrast, in-situ recovery leaches minerals directly within the ore without excavation, minimizing surface disturbance but is limited to porous ore bodies and generally yields lower overall recovery compared to sublevel stoping.

Paste Backfill

Paste backfill enhances underground mining by stabilizing excavated voids through the use of tailings mixed with binders, reducing surface subsidence and improving safety. In contrast, in-situ recovery bypasses backfilling by dissolving minerals underground and pumping solutions to the surface, emphasizing minimal surface disturbance but lacking structural support provided by paste backfill.

Hydraulic Fracturing (ISR context)

Underground mining involves extensive excavation and physical extraction of ore through tunnels, while In-situ recovery (ISR) uses hydraulic fracturing to enhance permeability and facilitate the injection of lixiviants that dissolve minerals directly within the ore body. Hydraulic fracturing in ISR significantly reduces surface disturbance and water usage compared to conventional underground mining, making it an environmentally efficient method for extracting uranium and other soluble minerals.

Leach Solution Injection

Leach solution injection in in-situ recovery involves the controlled pumping of chemical solvents into the ore body to dissolve minerals without excavation, significantly reducing surface disturbance compared to underground mining. This method enhances resource extraction efficiency by targeting deposits in permeable rock formations, minimizing environmental impact and operational costs relative to traditional shaft and drift excavation techniques.

Acid In-situ Leaching

Acid In-situ Leaching (ISL) enhances uranium extraction by injecting acidic solutions directly into underground ore bodies, dissolving minerals without extensive excavation or surface disruption. This environmentally efficient method contrasts with traditional underground mining by minimizing waste rock production and surface footprint while requiring careful management of groundwater contamination risks.

Geochemical Monitoring (ISR)

Geochemical monitoring in underground mining focuses on tracking changes in groundwater and orebody chemistry to prevent environmental contamination and optimize extraction processes, while in-situ recovery (ISR) relies heavily on continuous geochemical analysis to control leachate composition and ensure the safe mobilization of minerals within the ore deposit. Advanced sensor technologies and real-time data integration are critical for both methods to accurately assess geochemical alterations and minimize ecological impacts during mineral recovery.

Mine Ventilation Automation

Underground mining requires advanced mine ventilation automation systems to ensure air quality and worker safety by continuously monitoring airflow, gas levels, and temperature in confined tunnels. In contrast, in-situ recovery relies less on ventilation automation as it involves minimal underground excavation, focusing more on controlling fluid injection and recovery processes.

Remote Orebody Mapping

Underground mining relies on direct excavation and tunnel access, enabling precise remote orebody mapping through advanced geophysical and sensor technologies to identify ore boundaries and structural features. In contrast, in-situ recovery depends on injecting solvents into the ore body, with remote sensing methods primarily focused on monitoring fluid flow and chemical distribution rather than detailed orebody geometry.

Underground mining vs In-situ recovery Infographic

industrydif.com

industrydif.com