Block caving is an underground mining method that exploits large, low-grade ore bodies by causing the rock to collapse under its own weight, enabling efficient bulk extraction. Seafloor massive sulfide mining targets rich deposits on the ocean floor formed by hydrothermal vents, offering high concentrations of metals like copper, zinc, and gold but posing significant environmental challenges due to ecosystem disruption. While block caving excels in terrestrial settings with established infrastructure, seafloor mining represents a frontier with potential for high yield but requires advanced technology and stringent environmental safeguards.

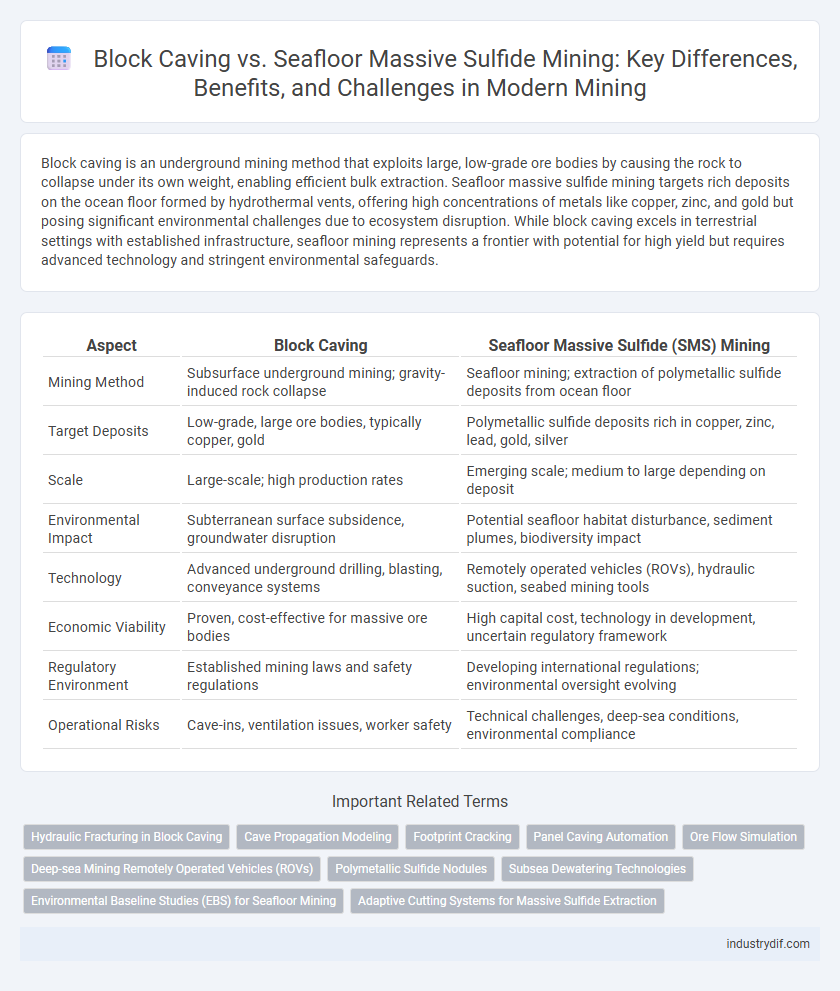

Table of Comparison

| Aspect | Block Caving | Seafloor Massive Sulfide (SMS) Mining |

|---|---|---|

| Mining Method | Subsurface underground mining; gravity-induced rock collapse | Seafloor mining; extraction of polymetallic sulfide deposits from ocean floor |

| Target Deposits | Low-grade, large ore bodies, typically copper, gold | Polymetallic sulfide deposits rich in copper, zinc, lead, gold, silver |

| Scale | Large-scale; high production rates | Emerging scale; medium to large depending on deposit |

| Environmental Impact | Subterranean surface subsidence, groundwater disruption | Potential seafloor habitat disturbance, sediment plumes, biodiversity impact |

| Technology | Advanced underground drilling, blasting, conveyance systems | Remotely operated vehicles (ROVs), hydraulic suction, seabed mining tools |

| Economic Viability | Proven, cost-effective for massive ore bodies | High capital cost, technology in development, uncertain regulatory framework |

| Regulatory Environment | Established mining laws and safety regulations | Developing international regulations; environmental oversight evolving |

| Operational Risks | Cave-ins, ventilation issues, worker safety | Technical challenges, deep-sea conditions, environmental compliance |

Overview of Block Caving and Seafloor Massive Sulfide Mining

Block caving is an underground mining method that exploits large, low-grade ore bodies by allowing the ore to collapse under its own weight, enabling efficient extraction with reduced operational costs. Seafloor massive sulfide (SMS) mining targets polymetallic sulfide deposits formed at hydrothermal vents on the ocean floor, containing valuable metals like copper, zinc, gold, and silver. While block caving emphasizes gravity-induced ore breakage in terrestrial mines, SMS mining involves remote-operated technologies to extract deep-sea mineral resources with minimal surface disturbance.

Geological Conditions Favorable for Each Method

Block caving is best suited for massive, low-grade ore bodies with strong rock mass and steeply dipping ore veins, primarily found in deep underground settings such as porphyry copper and iron ore deposits. Seafloor massive sulfide mining targets hydrothermal vent fields on the ocean floor, where high-temperature fluid emissions deposit rich accumulations of copper, zinc, gold, and silver in fractured basaltic crust. The geological conditions for block caving require competent rock to support large underground cavities, whereas seafloor massive sulfide mining relies on volcanic activity and tectonic spreading centers that create sulfide mineralization on or near the seabed.

Technical Process Comparison

Block caving involves undermining an ore body, causing it to collapse under its own weight, enabling gravity to transport fragmented material to extraction points, which is highly effective for massive, low-grade ore deposits. Seafloor massive sulfide (SMS) mining utilizes remotely operated vehicles and continuous mining systems to extract mineral-rich deposits directly from the ocean floor, focusing on limited disturbance and precision. The block caving process relies on gravity and natural fragmentation underground, whereas SMS mining emphasizes robotic technology and subsea material transport, reflecting distinct operational environments and technical complexities.

Equipment and Infrastructure Differences

Block caving relies on extensive underground infrastructure, including reinforced tunnels, drawpoints, and conveyor systems, designed to support heavy load equipment like load-haul-dump machines, crushers, and haul trucks. In contrast, seafloor massive sulfide mining requires specialized remotely operated vehicles (ROVs), subsea drills, and riser or lifting systems adapted for deep-sea environments, along with surface vessels equipped for ore extraction and transport. The terrestrial block caving approach demands robust ventilation and safety systems, whereas seafloor mining emphasizes waterproofing, pressure resistance, and dynamic positioning for floating platforms.

Resource Recovery Efficiency

Block caving offers high resource recovery efficiency by enabling the extraction of large, low-grade ore bodies with minimal dilution and lower operational costs. Seafloor massive sulfide (SMS) mining faces challenges in achieving comparable recovery rates due to the complex terrain and dispersed ore deposits on the ocean floor. Advanced technologies in SMS mining aim to improve bulk recovery, but block caving remains more efficient for extracting deep, extensive orebodies on land.

Environmental Impacts: Land vs. Seafloor

Block caving mining generates extensive land subsidence and disrupts terrestrial ecosystems, leading to habitat loss and soil erosion. Seafloor massive sulfide mining disturbs benthic habitats, causing sediment plumes and potential toxicity that threaten marine biodiversity. Both methods pose significant environmental challenges, but the spatial impact of block caving is terrestrial whereas seafloor mining affects deep-sea environments with longer recovery times.

Economic Viability and Cost Considerations

Block caving offers lower operating costs and higher production rates compared to traditional underground mining methods, making it economically viable for large, low-grade ore bodies. In contrast, seafloor massive sulfide (SMS) mining involves significant upfront capital expenditure due to advanced underwater equipment and environmental management requirements, which can challenge its short-term profitability. Economic viability in SMS mining depends heavily on metal prices, technological advancements, and regulatory frameworks that influence cost efficiency and risk mitigation.

Safety Risks and Mitigation Strategies

Block caving involves subterranean operations with risks like ground subsidence, rockfalls, and hazardous gas exposure, mitigated through comprehensive ground support, real-time monitoring, and ventilation systems. Seafloor massive sulfide mining presents challenges including deepwater pressure hazards, equipment corrosion, and ecosystem disruption, addressed by deploying remotely operated vehicles, corrosion-resistant materials, and environmental impact assessments. Both mining methods require rigorous risk management frameworks to safeguard workers and minimize environmental impact during extraction processes.

Regulatory and Compliance Challenges

Block caving faces stringent regulatory and compliance challenges related to land use, subsidence risks, and groundwater management, requiring extensive environmental impact assessments and continuous monitoring. Seafloor massive sulfide mining presents complex jurisdictional issues under international maritime law, with compliance hurdles in protecting fragile deep-sea ecosystems and adherence to international seabed authority regulations. Both methods demand robust frameworks to address environmental, social, and safety standards, emphasizing transparency and stakeholder engagement.

Future Trends in Subsurface and Seafloor Mining

Future trends in subsurface and seafloor mining emphasize the integration of advanced automation and real-time data analytics to enhance extraction efficiency and environmental management. Block caving techniques are evolving with AI-driven predictive maintenance and improved ventilation systems, while seafloor massive sulfide mining focuses on remotely operated vehicles (ROVs) and sustainable practices to minimize ecological impact. The convergence of these technologies aims to optimize resource recovery from challenging environments while adhering to stricter regulatory frameworks and environmental standards.

Related Important Terms

Hydraulic Fracturing in Block Caving

Hydraulic fracturing in block caving enhances rock permeability by creating controlled fractures, facilitating efficient ore extraction from deep underground deposits. This contrasts with seafloor massive sulfide mining, which targets mineral-rich deposits on the ocean floor without relying on subsurface fracturing techniques.

Cave Propagation Modeling

Cave propagation modeling in block caving utilizes advanced numerical simulations to predict subsidence and fragmentation patterns, optimizing extraction efficiency and minimizing operational risks in underground mines. In contrast, seafloor massive sulfide mining requires limited cave propagation analysis due to its surface-based, marine environment, emphasizing geotechnical stability and sediment displacement over subsurface cave behavior.

Footprint Cracking

Block caving creates extensive subsidence and surface cracking due to large-scale underground void collapse, impacting land stability over vast mining footprints. Seafloor massive sulfide mining induces localized sediment disruption and seabed fracturing, but its footprint cracking is generally more confined compared to terrestrial block caving operations.

Panel Caving Automation

Panel caving automation in block caving enhances ore recovery and operational safety by integrating advanced robotics, real-time monitoring, and data analytics to efficiently manage cave propagation and fragment movement. In contrast, seafloor massive sulfide mining faces challenges in automation due to harsh underwater conditions, requiring remotely operated vehicles and sophisticated sensor networks for precise extraction and environmental monitoring.

Ore Flow Simulation

Block caving employs gravity-driven ore flow simulation to optimize the collapse and draw of fragmented rock, enhancing operational efficiency in large, low-grade underground deposits. Seafloor massive sulfide mining relies on remotely operated vehicle simulations to model sediment disturbance and ore transport, ensuring precise extraction of polymetallic sulfide deposits on the ocean floor.

Deep-sea Mining Remotely Operated Vehicles (ROVs)

Deep-sea mining remotely operated vehicles (ROVs) enable precise extraction of seafloor massive sulfide deposits in oceanic environments, offering access to mineral-rich deposits unattainable by traditional block caving methods used in terrestrial mining. Advanced ROV technologies provide real-time data collection, high-resolution imaging, and targeted material recovery, optimizing efficiency and minimizing environmental impact compared to the extensive underground excavation in block caving.

Polymetallic Sulfide Nodules

Block caving is an underground mining method used to extract large ore bodies with lower operational costs, while seafloor massive sulfide (SMS) mining targets polymetallic sulfide nodules rich in copper, zinc, gold, and silver from the ocean floor. Polymetallic sulfide nodules found in SMS deposits present a significant potential for sourcing critical metals with minimal surface disruption compared to terrestrial block caving mining.

Subsea Dewatering Technologies

Subsea dewatering technologies in block caving involve managing groundwater and inflows within underground voids to optimize ore extraction and prevent collapses, utilizing advanced pumping and grouting systems. In contrast, seafloor massive sulfide mining employs specialized subsea dewatering methods to control sediment dispersion and water intrusion at the ocean floor, relying on remotely operated vehicles and subsea pumps to maintain environmental stability during mineral recovery.

Environmental Baseline Studies (EBS) for Seafloor Mining

Environmental Baseline Studies (EBS) for seafloor massive sulfide mining involve comprehensive assessments of marine ecosystems, including biodiversity inventories, sediment composition, and water chemistry to evaluate potential impacts on deep-sea habitats. Unlike block caving, which primarily affects terrestrial landscapes, seafloor mining EBS must address the complexity of underwater environments, focusing on long-term monitoring of ecological changes and contamination from sediment plumes and heavy metals.

Adaptive Cutting Systems for Massive Sulfide Extraction

Adaptive cutting systems in block caving enhance ore recovery efficiency and reduce dilution by precisely targeting weak rock structures, while in seafloor massive sulfide mining, these systems are optimized for fragile, sulfide-rich deposits under high-pressure underwater conditions to minimize environmental impact and maximize metal yield. Advanced sensor integration and real-time data analytics allow adaptive cutting technologies to adjust cutting parameters dynamically, improving operational safety and resource extraction in both terrestrial and marine mining environments.

Block caving vs Seafloor massive sulfide mining Infographic

industrydif.com

industrydif.com