Tailings dams store mining waste as a slurry in large impoundments, which requires continuous water management and poses significant environmental risks due to potential dam failures. Dry stack tailings involve dewatering the waste to create a solid, stackable material that reduces water usage and minimizes the risk of catastrophic releases. This method offers improved stability and lower environmental impact, making it a safer and more sustainable option for tailings management in mining operations.

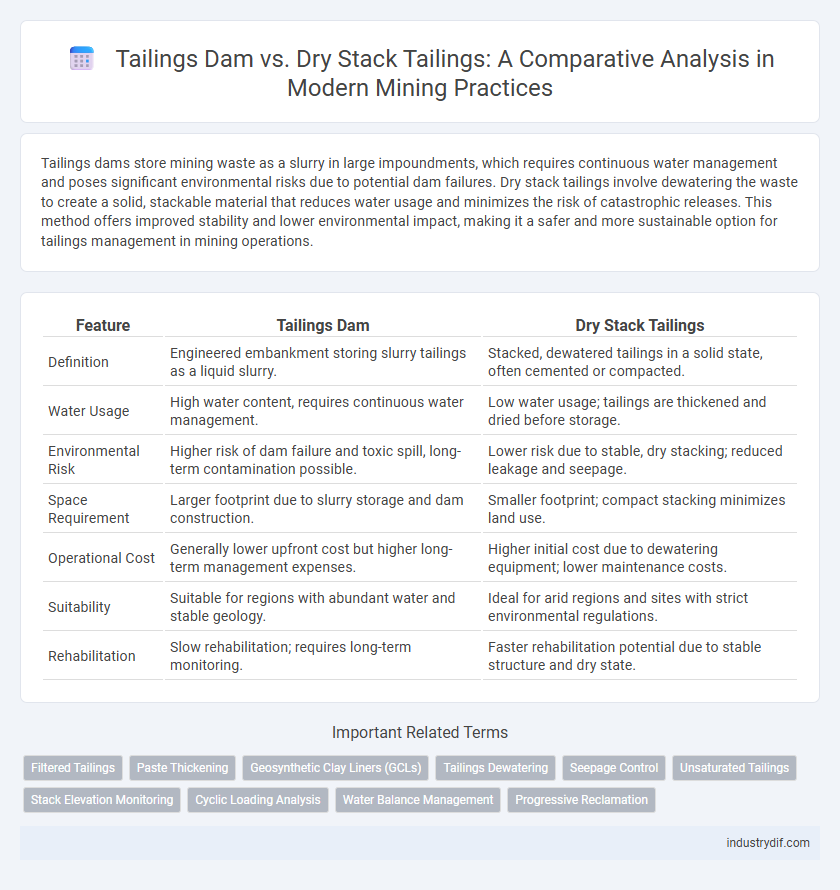

Table of Comparison

| Feature | Tailings Dam | Dry Stack Tailings |

|---|---|---|

| Definition | Engineered embankment storing slurry tailings as a liquid slurry. | Stacked, dewatered tailings in a solid state, often cemented or compacted. |

| Water Usage | High water content, requires continuous water management. | Low water usage; tailings are thickened and dried before storage. |

| Environmental Risk | Higher risk of dam failure and toxic spill, long-term contamination possible. | Lower risk due to stable, dry stacking; reduced leakage and seepage. |

| Space Requirement | Larger footprint due to slurry storage and dam construction. | Smaller footprint; compact stacking minimizes land use. |

| Operational Cost | Generally lower upfront cost but higher long-term management expenses. | Higher initial cost due to dewatering equipment; lower maintenance costs. |

| Suitability | Suitable for regions with abundant water and stable geology. | Ideal for arid regions and sites with strict environmental regulations. |

| Rehabilitation | Slow rehabilitation; requires long-term monitoring. | Faster rehabilitation potential due to stable structure and dry state. |

Understanding Tailings Management in Mining

Tailings dams are engineered structures designed to store wet tailings slurry, but they pose risks such as dam failure and environmental contamination. Dry stack tailings involve dewatering tailings to create a dry, stable material that can be safely stacked, reducing water use and minimizing the risk of catastrophic dam breaches. Effective tailings management in mining prioritizes dry stack technology to enhance environmental sustainability and improve operational safety.

What Are Tailings Dams?

Tailings dams are engineered structures designed to store byproducts of mining operations, primarily consisting of fine-grained waste materials and water. These dams help contain tailings to prevent environmental contamination and ensure operational safety. Compared to dry stack tailings, tailings dams require continuous water management and pose higher risks of structural failure.

Introduction to Dry Stack Tailings

Dry stack tailings represent an innovative method of mine waste management where tailings are dewatered to create a stackable, low-moisture material, significantly reducing the risks associated with conventional tailings dams. This technology enhances environmental safety by minimizing the potential for dam failure, reducing groundwater contamination, and facilitating easier reclamation of mining sites. Mining operations adopting dry stack tailings benefit from improved regulatory compliance and long-term sustainability in tailings disposal.

Key Differences Between Tailings Dams and Dry Stack Tailings

Tailings dams store mining waste in large, water-saturated impoundments with potential risks of structural failure and environmental contamination. Dry stack tailings involve dewatered tailings compacted into dry, stable piles with reduced water use and lower environmental impact. Key differences include water usage, storage method, stability, and environmental safety, where dry stacking offers enhanced tailings management and reduced risk of dam breach.

Environmental Impact: Tailings Dam vs Dry Stack Tailings

Tailings dams pose significant environmental risks including potential dam failure, toxic leakage, and groundwater contamination, leading to severe ecological damage. Dry stack tailings significantly reduce these hazards by using filtered, solid materials that minimize water usage and prevent seepage. This approach enhances environmental safety through improved stability and lowers the risk of catastrophic tailings release.

Safety and Risk Assessment

Tailings dams present significant safety risks due to potential structural failures leading to catastrophic environmental damage and loss of life, whereas dry stack tailings reduce these hazards by eliminating liquid waste storage and enhancing stability through compaction. Risk assessment in tailings management prioritizes factors such as dam height, seismic activity, and tailings geochemistry, favoring dry stacking methods in high-risk seismic zones for their lower failure probability. Enhanced monitoring and dewatering technologies improve the safety profile of dry stack tailings, making them a preferred choice in modern mining operations focused on sustainable risk mitigation.

Cost Comparison: Construction and Maintenance

Tailings dams typically involve higher initial construction costs due to the need for extensive earthworks, water management systems, and engineered embankments, but may offer lower short-term maintenance expenses. Dry stack tailings require specialized equipment for dewatering and compacting tailings, leading to increased upfront investment and ongoing operational costs, but significantly reduce long-term risks and rehabilitation expenses. Lifecycle cost analysis often favors dry stack tailings in regions with stringent environmental regulations or seismic activity, despite their higher initial expenditure.

Water Usage and Conservation

Tailings dams require large volumes of water to maintain slurry consistency, leading to significant water consumption and potential contamination risks. Dry stack tailings minimize water usage by dewatering tailings through filtration, enabling safer and more efficient storage with reduced environmental impact. This method enhances water conservation efforts in mining operations by recycling process water and decreasing dependency on freshwater resources.

Regulatory Compliance and Industry Standards

Tailings dams require strict adherence to regulatory compliance frameworks established by mining authorities, emphasizing structural stability and environmental protection to prevent catastrophic failures. Dry stack tailings are increasingly favored due to their alignment with industry standards for sustainable waste management, offering reduced water usage and lower contamination risks. Regulatory bodies often mandate comprehensive monitoring and reporting protocols for both methods, prioritizing safety and minimizing ecological impact throughout the mining lifecycle.

Future Trends in Tailings Disposal Technologies

Emerging trends in tailings disposal emphasize the transition from conventional tailings dams to dry stack tailings, driven by enhanced safety and environmental concerns. Dry stack tailings technology reduces water use by up to 90%, mitigates catastrophic dam failure risks, and enables easier reclamation of mining sites. Innovations in filtration and dewatering equipment continue to improve efficiency, positioning dry stack tailings as the preferred sustainable solution for future mining operations.

Related Important Terms

Filtered Tailings

Filtered tailings in dry stack tailings management reduce the risk of dam failure by removing water content and allowing safer, more stable storage compared to conventional tailings dams. This method enhances environmental compliance and minimizes potential contamination by limiting seepage and improving tailings consolidation.

Paste Thickening

Paste thickening technology significantly reduces water content in tailings, enabling the production of dry stack tailings, which offer enhanced stability and lower environmental risk compared to conventional tailings dams. Dry stack tailings also decrease the footprint of tailings storage facilities and minimize potential dam failure hazards by eliminating large-scale water impoundments.

Geosynthetic Clay Liners (GCLs)

Geosynthetic Clay Liners (GCLs) enhance the containment performance of Tailings Dams by providing a low-permeability barrier that minimizes seepage and contaminant migration, crucial for environmental protection in mining operations. In Dry Stack Tailings, GCLs contribute to structural stability and water retention efficiency, enabling safer tailings management with reduced environmental footprint and lower risk of dam failure.

Tailings Dewatering

Tailings Dewatering plays a crucial role in enhancing the stability and environmental safety of Tailings Dams by reducing water content and minimizing seepage risks. Dry Stack Tailings, achieved through advanced dewatering techniques, provide a safer alternative with lower water retention, allowing for easier waste management and reduced potential for catastrophic dam failures.

Seepage Control

Tailings dams rely on engineered embankments to contain slurry but pose higher seepage risks due to water saturation and potential structural failure. Dry stack tailings significantly reduce seepage by utilizing filtered, dewatered tailings that enhance stability and minimize environmental contamination.

Unsaturated Tailings

Unsaturated tailings in dry stack tailings management significantly reduce water content, enhancing dam stability and minimizing seepage risks compared to conventional tailings dams. This approach improves environmental safety by preventing saturation-induced failures and facilitating safer tailings disposal in mining operations.

Stack Elevation Monitoring

Stack elevation monitoring in tailings dams relies on radar and drone surveys to track water-saturated sludge height, mitigating breach risks associated with rising liquid levels. Dry stack tailings enable easier, more precise surface elevation control through ground-based laser scanning, reducing environmental hazards and improving structural stability.

Cyclic Loading Analysis

Cyclic loading analysis of tailings dams involves evaluating their response to repeated stress from seismic activity or operational vibrations to ensure structural stability and prevent catastrophic failure. Dry stack tailings, with their higher shear strength and reduced pore water pressure, exhibit superior performance under cyclic loading, minimizing deformation and liquefaction risks compared to conventional tailings dams.

Water Balance Management

Tailings dams require continuous water management to maintain structural stability and prevent seepage, often leading to significant water losses and environmental risks. Dry stack tailings drastically reduce water usage through thickened or filtered tailings, enhancing water recovery and minimizing the potential for dam failure and contamination.

Progressive Reclamation

Tailings dams store mine waste in large water-retained embankments, requiring ongoing monitoring and posing significant environmental risks, whereas dry stack tailings involve dewatered, compacted waste that enables progressive reclamation by allowing immediate land rehabilitation and reducing water contamination. Progressive reclamation in dry stacking accelerates ecosystem restoration, minimizes long-term liabilities, and enhances operational sustainability compared to conventional tailings dam methods.

Tailings Dam vs Dry Stack Tailings Infographic

industrydif.com

industrydif.com