Truck and shovel systems provide flexibility and ease of deployment in mining operations, enabling efficient material extraction and transport over varied terrains. Trolley assist systems enhance fuel efficiency and reduce emissions by using overhead electric lines to power trucks on uphill hauls, significantly lowering operating costs. Choosing between these systems depends on factors such as mine layout, haul distance, and environmental goals, with trolley assist offering substantial benefits in long-distance, uphill applications.

Table of Comparison

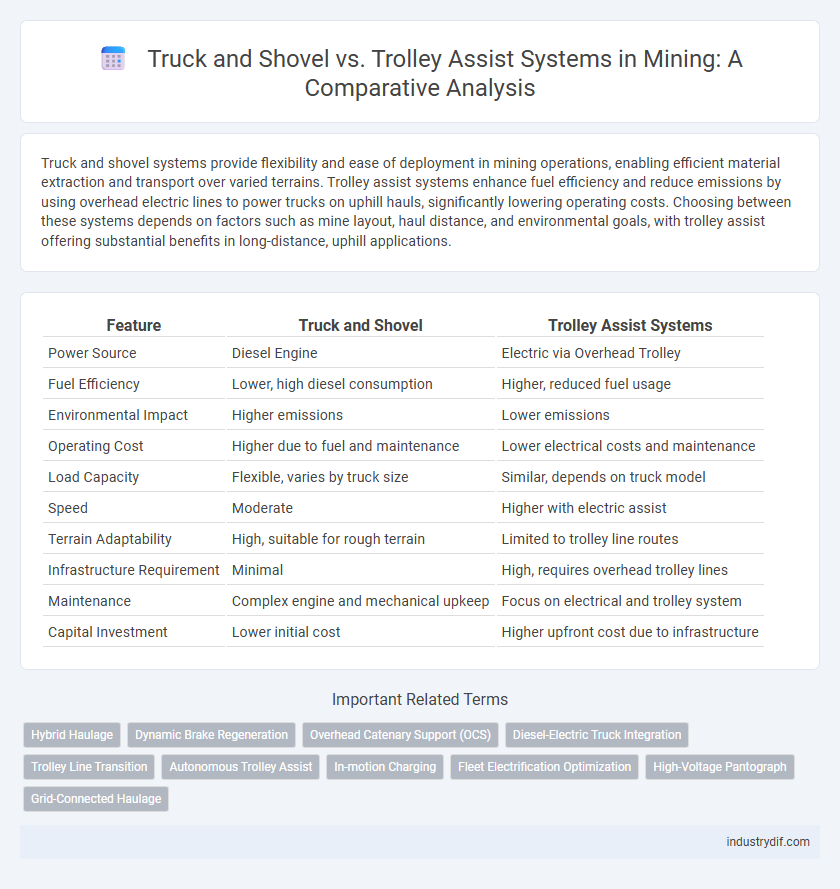

| Feature | Truck and Shovel | Trolley Assist Systems |

|---|---|---|

| Power Source | Diesel Engine | Electric via Overhead Trolley |

| Fuel Efficiency | Lower, high diesel consumption | Higher, reduced fuel usage |

| Environmental Impact | Higher emissions | Lower emissions |

| Operating Cost | Higher due to fuel and maintenance | Lower electrical costs and maintenance |

| Load Capacity | Flexible, varies by truck size | Similar, depends on truck model |

| Speed | Moderate | Higher with electric assist |

| Terrain Adaptability | High, suitable for rough terrain | Limited to trolley line routes |

| Infrastructure Requirement | Minimal | High, requires overhead trolley lines |

| Maintenance | Complex engine and mechanical upkeep | Focus on electrical and trolley system |

| Capital Investment | Lower initial cost | Higher upfront cost due to infrastructure |

Introduction to Truck and Shovel Operations

Truck and shovel operations form the core of surface mining activities, involving large diesel or electric trucks transporting excavated materials from shovels to processing or dumping sites. Shovels are designed to efficiently load these trucks with high payload capacities, optimizing cycle times and improving overall productivity in mining pits. Comparing traditional truck and shovel setups with trolley assist systems reveals key differences in fuel efficiency, operational costs, and environmental impacts specific to heavy-duty hauling in rugged mining terrains.

Overview of Trolley Assist Systems

Trolley Assist Systems integrate electric trolley lines with haul trucks to reduce diesel fuel consumption and lower greenhouse gas emissions in mining operations. These systems enable trucks to draw power from overhead electric cables while ascending grades, improving energy efficiency and increasing haul speeds. By combining electric propulsion with traditional truck mobility, Trolley Assist optimizes fuel savings and enhances operational productivity in surface mining.

Key Components and Technologies

Truck and Shovel systems rely on large haul trucks and electric or diesel hydraulic shovels, featuring powerful engines, heavy-duty tires, and robust digging arms equipped with advanced sensors for precision loading. Trolley Assist Systems incorporate electric trolley lines supplying continuous power to haul trucks via pantographs, reducing fuel consumption and emissions by replacing diesel engines during uphill hauls. Key technologies in Trolley Assist include high-voltage electrification infrastructure, regenerative braking systems for energy recovery, and real-time monitoring software to optimize power usage and vehicle performance.

Comparative Operational Efficiencies

Truck and shovel systems offer flexible hauling routes and rapid response times, making them ideal for variable terrain and smaller operations. In contrast, trolley assist systems enhance fuel efficiency and haul capacity by providing electric power to trucks on fixed routes, significantly reducing diesel consumption. Operational efficiency gains in trolley assist systems are maximized in high-production mines with consistent loading and hauling cycles.

Environmental Impact: Emissions and Sustainability

Truck and Shovel systems typically produce higher emissions due to diesel-powered haul trucks, contributing significantly to greenhouse gas output in mining operations. Trolley Assist Systems utilize electric-powered haul trucks connected to overhead power lines, reducing diesel consumption and lowering carbon emissions substantially. This transition enhances sustainability by minimizing air pollution and promoting energy efficiency in large-scale mining projects.

Cost Analysis: Capital and Operating Expenditures

Truck and shovel systems typically incur higher capital expenditures due to the need for multiple large trucks and associated maintenance facilities, whereas trolley assist systems require significant upfront investment in electrified infrastructure such as overhead lines and substations. Operating expenditures for truck and shovel setups are elevated by fuel consumption and engine maintenance, while trolley assist systems benefit from lower energy costs and reduced diesel usage, leading to long-term savings. Cost analysis must consider lifecycle expenses, with trolley assist systems offering greater efficiency and reduced carbon emissions, making them more economically viable in high production mining operations.

Productivity and Cycle Time Comparison

Truck and Shovel systems typically offer flexible operational capacity but face significant delays during haulage and loading cycles, resulting in longer average cycle times compared to Trolley Assist Systems. Trolley Assist Systems enhance productivity by reducing fuel consumption and improving cycle times through electric-powered haul trucks that maintain higher speeds on haul roads. Studies show that Trolley Assist can decrease cycle times by up to 15%, leading to improved overall equipment effectiveness and increased mine site throughput.

Safety Considerations in Both Systems

Truck and shovel systems present safety challenges such as operator visibility limitations and potential collisions within the pit, while trolley assist systems reduce diesel emissions and heat exposure, enhancing respiratory safety for workers. Trolley assist systems offer improved braking control and reduced wear on truck components due to electric propulsion, decreasing mechanical failure risks. Both systems require rigorous training and maintenance protocols to mitigate accident risks and ensure safe material handling in mining operations.

Integration Challenges and Infrastructure Requirements

Integrating truck and shovel systems with trolley assist technology in mining operations demands significant infrastructure modifications, including the installation of overhead electric lines and substations to power haul trucks. Challenges arise from coordinating the dynamic interactions between traditional diesel trucks and electrically assisted vehicles, requiring advanced control systems to manage speed, braking, and power transfer seamlessly. Infrastructure investment and operational adjustments are critical to optimize productivity while maintaining safety standards in the hybrid haulage environment.

Future Trends in Haulage Systems

Future haulage systems in mining increasingly integrate advanced Truck and Shovel operations with Trolley Assist technology to reduce fuel consumption and lower greenhouse gas emissions. Emerging trends emphasize electric and autonomous haul trucks supported by trolley assist infrastructure, improving energy efficiency and operational productivity. Adoption of smart haulage systems with real-time data analytics enhances fleet management and minimizes downtime, driving cost-efficient and sustainable mining operations.

Related Important Terms

Hybrid Haulage

Hybrid haulage systems combining truck and shovel operations with trolley assist technology enhance fuel efficiency and reduce greenhouse gas emissions in mining transport. These systems optimize payload delivery by integrating electric trolley lines on inclines, lowering operational costs while improving equipment lifespan and site productivity.

Dynamic Brake Regeneration

Truck and Shovel systems typically rely on conventional braking methods, whereas Trolley Assist Systems enhance energy efficiency through dynamic brake regeneration by converting kinetic energy into electrical power during downhill haulage. This regenerative braking reduces fuel consumption and lowers emissions, making Trolley Assist a more sustainable solution for high-gradient mining operations.

Overhead Catenary Support (OCS)

Overhead Catenary Support (OCS) systems in trolley assist technology provide continuous electric power to mining trucks, significantly reducing diesel fuel consumption and emissions compared to traditional truck and shovel operations. The integration of OCS enables higher haulage speeds and increased payload capacity while minimizing maintenance costs and environmental impact in large-scale surface mining operations.

Diesel-Electric Truck Integration

Diesel-electric truck integration enhances mining efficiency by combining the power of diesel engines with electric propulsion, reducing fuel consumption and emissions compared to traditional truck and shovel systems. Trolley assist systems further optimize this integration by supplying electric power via overhead lines, allowing trucks to operate with reduced diesel engine load during uphill hauls, resulting in lower operational costs and extended equipment lifespan.

Trolley Line Transition

Trolley assist systems enhance mining truck efficiency by providing continuous electric power through overhead lines, reducing fuel consumption and emissions compared to traditional truck and shovel operations. The trolley line transition, involving seamless switching between trolley-powered and diesel mode, minimizes downtime and optimizes haul cycles in varied terrain and load conditions.

Autonomous Trolley Assist

Autonomous trolley assist systems enhance mining truck efficiency by enabling electric haulage using overhead catenary power lines, reducing fuel consumption and emissions compared to traditional truck and shovel operations. These systems improve haul cycle times and operational sustainability by coupling automated trucks with electric trolley infrastructure, optimizing energy use in large-scale open-pit mining environments.

In-motion Charging

In-motion charging systems for truck and shovel operations enhance productivity by reducing downtime associated with battery swaps or charging stops, enabling continuous hauling cycles. Trolley assist systems utilize overhead electric lines to power trucks during uphill hauls, decreasing diesel fuel consumption and emissions while maintaining high payload capacity and operational efficiency.

Fleet Electrification Optimization

Truck and Shovel systems offer flexibility but higher emissions compared to Trolley Assist Systems, which significantly reduce diesel consumption by enabling electric-powered haul trucks on overhead catenary wires. Fleet electrification optimization in mining maximizes energy efficiency and lowers operational costs by integrating trolley assist technologies with battery-powered trucks for seamless transition during non-trolley segments.

High-Voltage Pantograph

High-voltage pantograph trolley assist systems enhance mining truck operations by providing continuous electric power through overhead lines, significantly reducing fuel consumption and emissions compared to traditional truck and shovel methods. These systems enable higher payload capacities and improved cycle times, optimizing productivity in open-pit mining environments.

Grid-Connected Haulage

Grid-connected haulage in mining enables trolley assist systems to reduce diesel consumption by up to 30%, increasing energy efficiency compared to traditional truck and shovel operations. Integrating electric trolley lines with haul trucks improves productivity and lowers greenhouse gas emissions by utilizing renewable electricity from the grid.

Truck and Shovel vs Trolley Assist Systems Infographic

industrydif.com

industrydif.com