Traditional blasting in mining relies on predetermined explosive charges to fragment rock, often resulting in unpredictable ground vibrations and potential structural damage. Microseismic monitoring offers real-time data on seismic events during blasting, enabling precise control and enhanced safety by minimizing unwanted ground movement. Integrating microseismic technology reduces environmental impact and improves operational efficiency compared to conventional blasting methods.

Table of Comparison

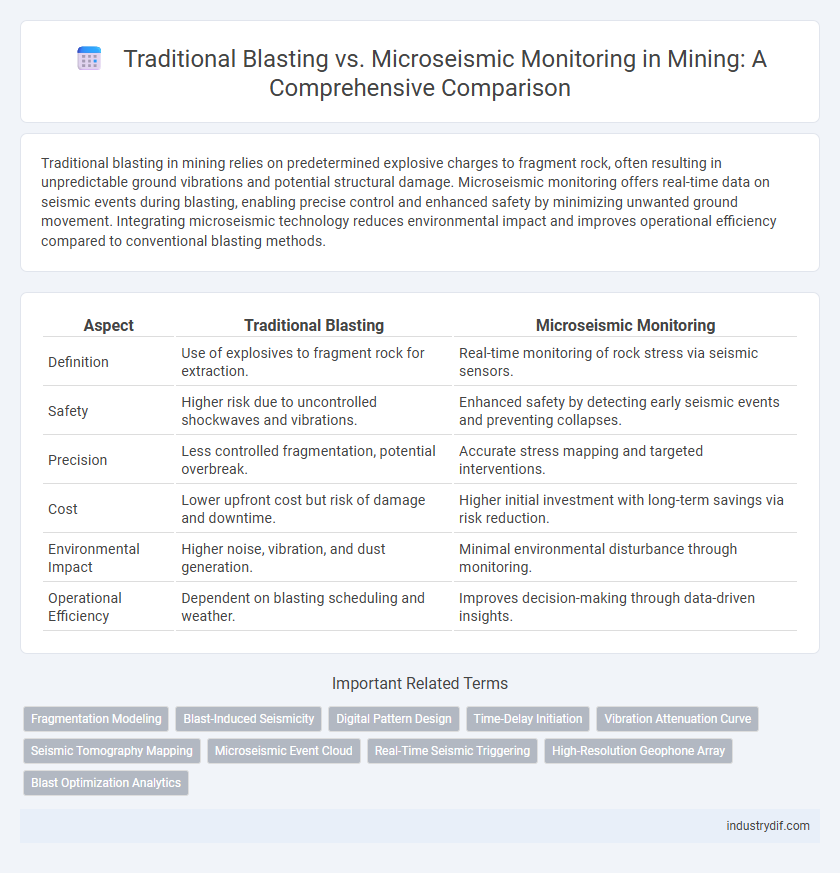

| Aspect | Traditional Blasting | Microseismic Monitoring |

|---|---|---|

| Definition | Use of explosives to fragment rock for extraction. | Real-time monitoring of rock stress via seismic sensors. |

| Safety | Higher risk due to uncontrolled shockwaves and vibrations. | Enhanced safety by detecting early seismic events and preventing collapses. |

| Precision | Less controlled fragmentation, potential overbreak. | Accurate stress mapping and targeted interventions. |

| Cost | Lower upfront cost but risk of damage and downtime. | Higher initial investment with long-term savings via risk reduction. |

| Environmental Impact | Higher noise, vibration, and dust generation. | Minimal environmental disturbance through monitoring. |

| Operational Efficiency | Dependent on blasting scheduling and weather. | Improves decision-making through data-driven insights. |

Overview of Blasting Techniques in Mining

Traditional blasting in mining involves controlled explosions to fragment rock, using explosives such as ANFO or emulsions, optimizing ore extraction efficiency and safety. Microseismic monitoring enhances blasting techniques by capturing seismic waves generated during blasts, providing real-time data on rock response and fracture development. Integrating microseismic monitoring with traditional blasting improves blast design, reduces environmental impact, and increases operational precision.

Fundamentals of Traditional Blasting

Traditional blasting in mining involves the controlled use of explosives to fragment rock, relying on seismic energy and blast design parameters to optimize fracture patterns. Key factors include charge placement, timing sequences, and explosive type to maximize fragmentation while minimizing ground vibration and fly rock. This method depends heavily on empirical data and experience to ensure safety and efficiency in rock breakage.

Introduction to Microseismic Monitoring

Microseismic monitoring offers a precise method to detect and analyze rock fracturing events induced by mining activities, providing real-time subsurface data that traditional blasting methods lack. Unlike conventional blasting, which relies on pre-set charges and empirical models, microseismic technology captures seismic waves generated by fracturing to map stress changes and optimize blast design. Implementing microseismic monitoring enhances safety by predicting rockburst hazards and improves resource recovery through detailed fracture characterization.

Key Differences Between Blasting and Microseismic Monitoring

Traditional blasting in mining relies on controlled explosive detonations to break rock, focusing primarily on fragmentation and excavation efficiency. Microseismic monitoring, however, offers real-time detection and analysis of seismic events caused by mining activities, enabling precise assessment of rock stability and stress changes. The key difference lies in blasting as a mechanical process, whereas microseismic monitoring serves as a sophisticated measurement technique for enhancing safety and operational decision-making.

Safety Implications: Blasting vs Microseismic Monitoring

Traditional blasting in mining often poses significant safety risks due to unpredictable ground vibrations and potential flyrock hazards, which can lead to structural damage and worker injuries. Microseismic monitoring provides a safer alternative by continuously detecting and analyzing small-scale seismic events, allowing for real-time assessment of rock stability and proactive risk management. Enhanced accuracy in microseismic data enables miners to prevent hazardous conditions, thereby significantly reducing workplace accidents compared to conventional blasting methods.

Environmental Impact Assessment

Traditional blasting generates significant ground vibration, airblast, and dust, leading to habitat disruption and potential harm to nearby communities. Microseismic monitoring enables precise detection of seismic events induced by blasting, allowing real-time adjustments to minimize environmental disturbances. Environmental Impact Assessment incorporating microseismic data ensures optimized blast designs that reduce noise pollution, air quality degradation, and structural damage risks.

Cost Comparison and Operational Efficiency

Traditional blasting in mining often incurs higher overall costs due to extensive material usage, extensive labor, and increased downtime for safety compliance, while microseismic monitoring requires significant initial investment in technology but reduces operational disruptions and enhances precision. Microseismic monitoring enables real-time data collection and analysis, improving blast design and minimizing overbreak, which leads to lower post-blast remediation expenses and optimized resource extraction. Cost efficiency gains from microseismic monitoring stem from improved blast control, enhanced safety measures, and reduced environmental impact, ultimately resulting in more sustainable and economically viable mining operations.

Data Collection and Analytics in Mining Operations

Traditional blasting in mining relies on preset parameters and empirical data, often resulting in limited real-time feedback and indirect assessment of rock fragmentation and seismic impacts. Microseismic monitoring employs advanced sensor networks and high-resolution data analytics to capture precise seismic events, enabling detailed characterization of fracture development and energy release patterns. Enhanced data collection through microseismic systems facilitates improved decision-making, optimized blast designs, and reduced operational risks by providing granular insights into subsurface responses during mining activities.

Advances in Mining Technology: From Blasting to Microseismic Solutions

Advances in mining technology have shifted from traditional blasting methods, which often cause uncontrolled ground vibrations and safety risks, to microseismic monitoring systems that provide precise, real-time data on rock movement. Microseismic solutions enhance operational safety by detecting seismic events early, optimizing blast designs, and minimizing environmental impact through better control of shockwaves. The integration of IoT sensors and AI analytics in microseismic monitoring allows for proactive risk management and improved resource extraction efficiency.

Future Trends in Mine Monitoring and Extraction Methods

Microseismic monitoring is transforming future mining by enabling precise detection of rock fractures and stress distributions, which enhances safety and optimizes extraction processes compared to traditional blasting methods that rely on less accurate shockwave propagation data. Advances in sensor technology and real-time data analysis allow microseismic systems to predict potential hazards and improve resource recovery efficiency, aligning with sustainable mining practices. Integration of AI and IoT with microseismic monitoring is expected to drive autonomous operations and smarter decision-making in mine extraction and environmental management.

Related Important Terms

Fragmentation Modeling

Traditional blasting techniques rely on empirical methods to estimate fragmentation size, often resulting in inconsistent rock breakage and suboptimal ore recovery. Microseismic monitoring enables real-time fragmentation modeling by capturing seismic wave data during blasting, allowing for precise control over blast parameters to optimize fragmentation and improve overall mine productivity.

Blast-Induced Seismicity

Traditional blasting in mining often causes unpredictable blast-induced seismicity, leading to potential safety hazards and unplanned operational delays. Microseismic monitoring provides real-time data on seismic events, enabling precise control and mitigation of blast-induced seismic risks to enhance mine safety and productivity.

Digital Pattern Design

Digital pattern design in traditional blasting relies on fixed parameters and empirical methods, often leading to less precise fragmentation and increased environmental impact. Microseismic monitoring enhances blasting accuracy by integrating real-time data to optimize blast timing and pattern, improving rock breakage efficiency and reducing seismic risks.

Time-Delay Initiation

Time-delay initiation in traditional blasting sequences controls the timing between explosive charges to optimize fragmentation and reduce vibrations. Microseismic monitoring enhances this process by providing real-time data on rock mass response, enabling precise adjustments to time delays for improved blast efficiency and safety.

Vibration Attenuation Curve

Traditional blasting techniques often rely on empirical vibration attenuation curves based on distance and charge weight, which can lack precision in predicting ground vibrations. Microseismic monitoring provides real-time, high-resolution data that refines vibration attenuation models, enabling more accurate control of blast-induced vibrations and improved safety in mining operations.

Seismic Tomography Mapping

Traditional blasting methods in mining rely on controlled explosions to fragment rock but often cause unpredictable seismic events and limited subsurface imaging resolution. Microseismic monitoring combined with seismic tomography mapping provides high-precision visualization of stress distribution and fracture propagation, enabling real-time assessment of rock mass stability and improved blast design efficiency.

Microseismic Event Cloud

Microseismic Event Cloud technology enables precise detection and mapping of fracture propagation and rock mass deformation during blasting, offering real-time data that enhances safety and operational efficiency in mining operations. Unlike traditional blasting methods that rely on pre-set explosive charges and visual assessments, microseismic monitoring provides detailed insights into event location, magnitude, and frequency, optimizing blast design and minimizing environmental impact.

Real-Time Seismic Triggering

Real-time seismic triggering in microseismic monitoring offers precise detection and immediate response to seismic events, significantly enhancing safety and operational efficiency compared to traditional blasting methods, which rely on pre-set timing and lack dynamic feedback. Integrating real-time data allows mining engineers to adjust blasting parameters instantly, reducing risks and minimizing equipment damage.

High-Resolution Geophone Array

High-resolution geophone arrays in microseismic monitoring provide precise detection and localization of seismic events, outperforming traditional blasting methods that rely on less accurate vibration measurements. This advanced technology enhances mine safety and operational efficiency by continuously capturing detailed subsurface activity data in real time.

Blast Optimization Analytics

Traditional blasting relies on predetermined explosive charges and timing, often leading to inefficiencies and excessive ground vibration, while microseismic monitoring employs real-time seismic data analysis to optimize blast design by accurately detecting rock fracturing and energy distribution. Blast optimization analytics, driven by microseismic monitoring, enhances fragmentation control, improves safety by minimizing environmental impacts, and maximizes resource recovery through precise adjustment of blast parameters.

Traditional blasting vs Microseismic monitoring Infographic

industrydif.com

industrydif.com