Manual sampling in mining offers precise control and adaptability for diverse geological conditions but is labor-intensive and time-consuming, limiting efficiency on large-scale projects. Automated core logging enhances data consistency and speeds up the processing of core samples through advanced imaging and AI technologies, reducing human error and improving overall productivity. Integrating automated systems with manual expertise maximizes accuracy while optimizing operational workflows in modern mining exploration.

Table of Comparison

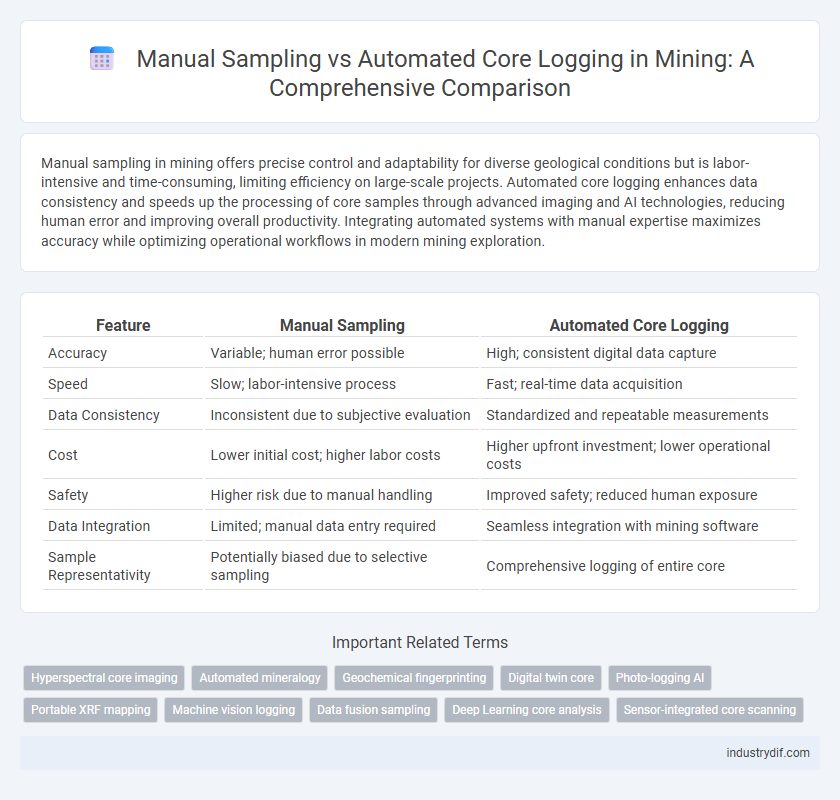

| Feature | Manual Sampling | Automated Core Logging |

|---|---|---|

| Accuracy | Variable; human error possible | High; consistent digital data capture |

| Speed | Slow; labor-intensive process | Fast; real-time data acquisition |

| Data Consistency | Inconsistent due to subjective evaluation | Standardized and repeatable measurements |

| Cost | Lower initial cost; higher labor costs | Higher upfront investment; lower operational costs |

| Safety | Higher risk due to manual handling | Improved safety; reduced human exposure |

| Data Integration | Limited; manual data entry required | Seamless integration with mining software |

| Sample Representativity | Potentially biased due to selective sampling | Comprehensive logging of entire core |

Introduction to Core Analysis in Mining

Manual sampling in core analysis involves physical extraction and visual inspection of rock cores, providing detailed lithological and structural information essential for precise geological interpretation. Automated core logging uses advanced imaging and sensor technologies like hyperspectral imaging, X-ray fluorescence (XRF), and machine learning algorithms to rapidly analyze core samples, increasing data consistency and reducing human bias. Combining both methods enhances the accuracy and efficiency of mineral resource estimation and geological modeling in mining exploration.

Defining Manual Sampling in Mining Operations

Manual sampling in mining operations involves physically collecting rock or mineral samples directly from drill cores or mining benches by trained geologists or technicians to assess ore quality and grade. This process relies on hands-on examination and precise sample selection to ensure representative analysis, crucial for resource modeling and exploration decisions. Compared to automated core logging, manual sampling provides tactile feedback and the ability to identify subtle visual features, although it is more time-consuming and subject to human error.

Understanding Automated Core Logging Technologies

Automated core logging technologies utilize high-resolution imaging, hyperspectral scanners, and AI-driven algorithms to analyze core samples with increased accuracy and efficiency compared to manual sampling. These systems provide detailed geological data, reduce human error, and enable real-time assessment of mineral content and structural features. Adoption of automated core logging enhances resource estimation and accelerates decision-making in mining exploration projects.

Key Differences: Manual vs Automated Core Logging

Manual core logging relies on geologists visually inspecting and recording core samples, providing detailed qualitative assessments but subject to human error and inconsistencies. Automated core logging employs advanced imaging technologies and machine learning algorithms to capture precise measurements and consistent data rapidly, enhancing accuracy and efficiency in mineral analysis. The key differences lie in data consistency, speed of processing, and reduction of subjective bias, with automated systems favoring large-scale, high-throughput mining operations.

Accuracy and Data Consistency in Core Sampling

Automated core logging systems significantly enhance accuracy by using high-resolution imaging and sensor technologies to capture detailed geological features consistently across all samples. Manual sampling often suffers from human error and subjective interpretation, leading to variability in data quality and reproducibility. Consistent digital records from automated methods improve data reliability, enabling more precise resource estimation and better decision-making in mining operations.

Efficiency and Speed of Core Analysis Methods

Manual sampling in mining offers detailed geological insights but is significantly slower, often requiring hours per core segment to capture accurate data. Automated core logging systems utilize advanced sensors and imaging technologies to process cores rapidly, reducing analysis time to minutes while maintaining precision. This efficiency boost enables accelerated decision-making and enhanced overall productivity in mining exploration and evaluation.

Cost Implications: Manual Sampling vs Automation

Manual sampling incurs higher labor costs and extended project timelines due to the intensive human effort required for sample collection and analysis. Automated core logging systems reduce these expenses by increasing processing speed, improving data accuracy, and minimizing human error, leading to significant cost savings over the lifecycle of mining projects. Investment in automation technology offers lower operational costs and enhances overall project efficiency compared to traditional manual methods.

Data Management and Integration Capabilities

Manual sampling in mining often leads to fragmented data sets due to inconsistent recording methods, challenging seamless data integration and management. Automated core logging utilizes advanced sensors and software platforms that enable real-time data capture, standardized formatting, and centralized storage, enhancing data accuracy and accessibility. These integration capabilities support comprehensive geological modeling and decision-making by providing interoperable datasets across various mining software systems.

Health and Safety Considerations in Sampling Techniques

Manual sampling in mining poses significant health and safety risks due to direct exposure to hazardous environments, such as unstable ground and airborne contaminants. Automated core logging systems reduce these risks by minimizing human presence in dangerous areas and using robotic arms and sensors for precise, remote sample analysis. Implementing automated core logging enhances worker safety, lowers accident rates, and ensures consistent sample quality in mining operations.

Future Trends in Core Logging for Mining Industry

Future trends in core logging for the mining industry emphasize automation technologies that enhance efficiency and data accuracy compared to manual sampling methods. Advanced automated core logging systems integrate hyperspectral imaging, 3D visualization, and AI-driven analytics to provide comprehensive geological analysis in real-time. These innovations reduce human error, accelerate decision-making, and support sustainable mining practices through precise mineral characterization and resource estimation.

Related Important Terms

Hyperspectral core imaging

Manual sampling in mining offers tactile assessment but is limited by human error and slower data acquisition rates, impacting the precision of mineral identification. Hyperspectral core imaging in automated core logging enhances detection accuracy by capturing detailed spectral data, enabling rapid, consistent analysis of mineral compositions and geological features in core samples.

Automated mineralogy

Automated core logging leverages advanced image analysis and mineralogical sensors to provide precise, real-time data on mineral distribution, significantly enhancing the accuracy and efficiency of mineralogical characterization compared to manual sampling. Automated mineralogy integrates technologies such as QEMSCAN(r) and MLA, facilitating rapid, consistent identification and quantification of ores, which supports improved resource modeling and decision-making in mining operations.

Geochemical fingerprinting

Manual sampling in mining relies heavily on operator skill for precise geochemical fingerprinting, offering detailed control but risking inconsistency due to human error. Automated core logging employs advanced sensors and AI algorithms to generate high-resolution geochemical data swiftly, enhancing accuracy and reproducibility in identifying mineral signatures.

Digital twin core

Manual sampling in mining involves physically collecting core samples, which can be time-consuming and prone to human error, whereas automated core logging utilizes advanced sensors and AI to capture precise geological data, enhancing accuracy and efficiency. Digital twin core technology integrates automated core logging data into a virtual model, enabling real-time analysis and predictive insights to optimize resource estimation and mine planning.

Photo-logging AI

Photo-logging AI significantly enhances automated core logging by providing high-resolution, consistent, and rapid analysis of core samples, reducing human error compared to manual sampling. This technology enables precise geological interpretation and efficient data integration, optimizing mineral exploration and resource estimation in mining operations.

Portable XRF mapping

Manual sampling in mining relies on physical core extraction and visual inspection, while automated core logging leverages advanced technologies like portable XRF mapping to provide real-time geochemical data with higher precision and efficiency. Portable XRF mapping enhances mineral identification and grade estimation by delivering rapid, in-situ elemental analysis, reducing sampling bias and accelerating decision-making processes.

Machine vision logging

Machine vision logging leverages high-resolution cameras and AI algorithms to provide precise, consistent, and rapid core analysis, reducing human error and increasing throughput compared to manual sampling methods. Automated core logging systems capture detailed lithological, structural, and textural data in real-time, optimizing resource estimation and improving decision-making efficiency in mining operations.

Data fusion sampling

Data fusion sampling in mining enhances accuracy by integrating manual sampling's hands-on detail with automated core logging's high-resolution digital data, enabling comprehensive geological analysis. Combining physical samples with sensor-derived measurements improves mineral identification and resource estimation, driving more informed decision-making in exploration and extraction.

Deep Learning core analysis

Deep learning core analysis enhances automated core logging by enabling precise mineral identification and structural characterization through image recognition algorithms, significantly reducing human error and processing time compared to manual sampling. This technology leverages large datasets and neural networks to improve accuracy in lithological classification and geochemical mapping, optimizing exploration and resource evaluation in mining operations.

Sensor-integrated core scanning

Sensor-integrated core scanning enhances automated core logging by providing high-resolution, real-time data on lithology, mineralogy, and structural features, surpassing the precision and consistency of manual sampling. This technology reduces human error, accelerates data acquisition, and enables more accurate geological modeling and resource estimation in mining operations.

Manual sampling vs Automated core logging Infographic

industrydif.com

industrydif.com