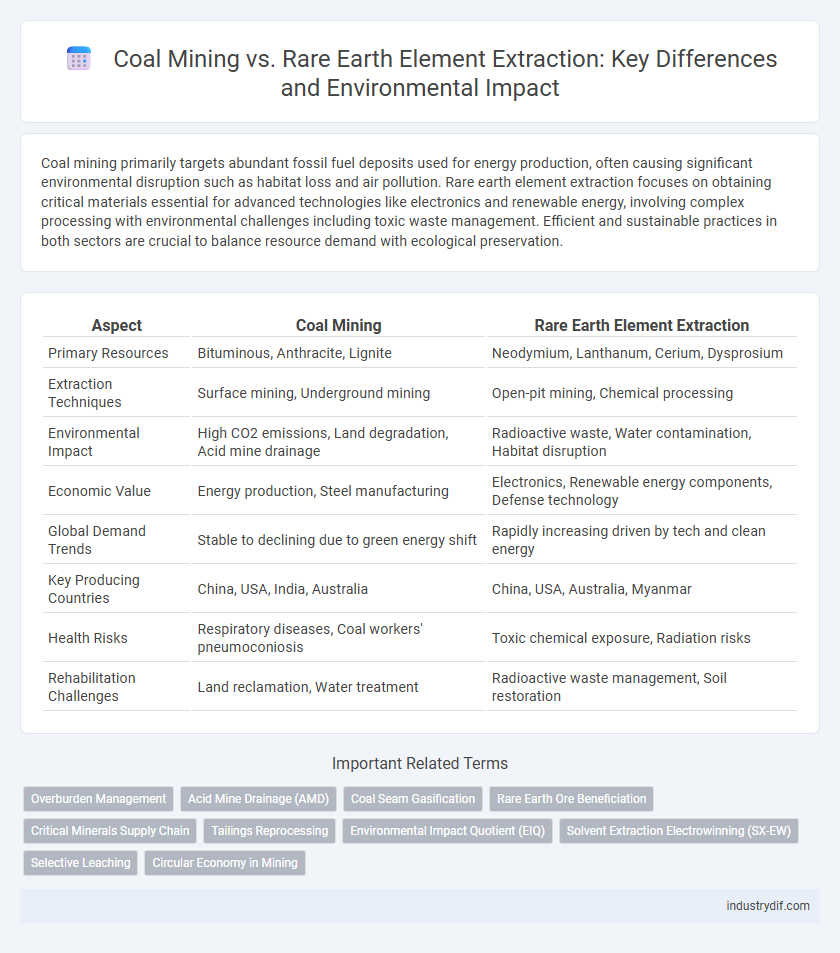

Coal mining primarily targets abundant fossil fuel deposits used for energy production, often causing significant environmental disruption such as habitat loss and air pollution. Rare earth element extraction focuses on obtaining critical materials essential for advanced technologies like electronics and renewable energy, involving complex processing with environmental challenges including toxic waste management. Efficient and sustainable practices in both sectors are crucial to balance resource demand with ecological preservation.

Table of Comparison

| Aspect | Coal Mining | Rare Earth Element Extraction |

|---|---|---|

| Primary Resources | Bituminous, Anthracite, Lignite | Neodymium, Lanthanum, Cerium, Dysprosium |

| Extraction Techniques | Surface mining, Underground mining | Open-pit mining, Chemical processing |

| Environmental Impact | High CO2 emissions, Land degradation, Acid mine drainage | Radioactive waste, Water contamination, Habitat disruption |

| Economic Value | Energy production, Steel manufacturing | Electronics, Renewable energy components, Defense technology |

| Global Demand Trends | Stable to declining due to green energy shift | Rapidly increasing driven by tech and clean energy |

| Key Producing Countries | China, USA, India, Australia | China, USA, Australia, Myanmar |

| Health Risks | Respiratory diseases, Coal workers' pneumoconiosis | Toxic chemical exposure, Radiation risks |

| Rehabilitation Challenges | Land reclamation, Water treatment | Radioactive waste management, Soil restoration |

Overview of Coal Mining and Rare Earth Element Extraction

Coal mining involves extracting coal deposits primarily from underground or surface mines, providing a critical energy source for electricity generation and industrial processes. Rare earth element extraction focuses on obtaining valuable minerals like neodymium and dysprosium, essential for advanced technologies such as electric vehicles and renewable energy systems. Both industries require complex geological assessments and environmental management to optimize resource recovery and minimize ecological impact.

Geological Formation and Resource Distribution

Coal mining primarily targets sedimentary basins formed from ancient plant debris compressed over millions of years, with significant deposits found in regions like the Appalachian Basin and the Bowen Basin. Rare earth element extraction focuses on igneous and metamorphic rocks such as carbonatites and alkaline intrusions, concentrated in geological provinces like China's Bayan Obo deposit and the Mountain Pass mine in the USA. The contrasting geological formations lead to diverse resource distributions, where coal is abundant in layered sedimentary sequences, while rare earths are scattered in complex mineral matrices requiring specialized extraction techniques.

Extraction Methods: Techniques and Technologies

Coal mining primarily employs surface mining and underground mining techniques, utilizing technologies such as continuous miners, longwall shearers, and draglines to efficiently extract coal seams from sedimentary rock formations. Rare earth element extraction involves more complex processes, including open-pit mining and in-situ leaching, followed by advanced chemical separation methods like solvent extraction, ion exchange, and hydrometallurgical techniques to isolate individual rare earth metals from ore concentrates. Innovations in bioleaching and sensor-based sorting improve resource recovery and reduce environmental impact in both coal and rare earth element extraction industries.

Environmental Impact Comparison

Coal mining causes extensive land degradation, water contamination from acid mine drainage, and significant air pollution from particulate matter and methane emissions. Rare earth element extraction involves complex chemical processes that generate toxic waste and radioactive byproducts, posing risks of soil and water pollution. Both mining activities contribute to habitat destruction, but rare earth element extraction often requires more intensive chemical management to mitigate environmental hazards.

Economic Value and Market Demand

Coal mining remains a cornerstone of the global energy market, with an annual value exceeding $600 billion, driven by extensive demand for electricity generation, steel production, and industrial fuel. In contrast, rare earth element extraction commands a rapidly growing market valued at approximately $20 billion, fueled by surging demand for high-tech applications such as electric vehicles, renewable energy technologies, and consumer electronics. The economic value of rare earth elements is amplified by their critical role in advanced manufacturing and limited global supply, positioning them as strategic commodities with significant future growth potential.

Labor Force and Occupational Hazards

Coal mining employs a larger labor force globally due to its extensive use in energy production, whereas rare earth element extraction requires specialized technicians with expertise in complex chemical processes. Occupational hazards in coal mining include respiratory diseases like pneumoconiosis and risks of mine collapses, while rare earth element extraction poses risks from exposure to toxic chemicals and radioactive materials during ore processing. The distinct labor demands and safety challenges of each mining sector necessitate tailored protective measures and workforce training to mitigate health risks effectively.

Regulatory Framework and Compliance

Coal mining is governed by well-established regulatory frameworks emphasizing environmental impact assessments, air and water quality standards, and land reclamation requirements under acts such as the Surface Mining Control and Reclamation Act (SMCRA) in the United States. Rare earth element extraction faces evolving and often more stringent regulations due to its association with radioactive waste management, chemical processing safety, and international trade controls to ensure supply chain security. Both sectors must comply with occupational health and safety standards, but rare earth mining requires additional oversight related to hazardous material handling and export restrictions.

Supply Chain and End-Use Applications

Coal mining primarily supports energy production and steel manufacturing, with an extensive supply chain involving extraction, transportation, and power generation industries. Rare earth element extraction serves critical high-tech and clean energy sectors, supplying materials essential for electronics, electric vehicles, and renewable energy technologies. The supply chain for rare earths is more complex, involving specialized processing and refining, often concentrated in specific geographic regions, impacting global trade and strategic resource security.

Waste Management and Land Rehabilitation

Coal mining generates vast amounts of overburden and tailings often containing toxic substances, necessitating robust waste management systems to prevent soil and water contamination. Rare earth element extraction produces radioactive and chemically complex waste that requires specialized treatment processes to mitigate environmental hazards. Land rehabilitation efforts in coal mining typically involve reshaping landscapes and restoring vegetation, whereas rare earth mining demands more intricate remediation due to its higher toxicity and potential long-term ecological impacts.

Future Trends and Industry Innovations

Coal mining is increasingly challenged by environmental regulations and declining demand, driving innovations in automation and methane capture technologies to reduce emissions and improve safety. Rare earth element extraction is experiencing accelerated research into sustainable mining techniques, such as bioleaching and solvent extraction, to meet soaring demand for electric vehicles and renewable energy components. Future trends highlight a shift towards integrating AI-driven resource assessment and circular economy practices to optimize both coal and rare earth material sourcing while minimizing ecological impact.

Related Important Terms

Overburden Management

Coal mining generates substantial volumes of overburden, requiring efficient stratification and disposal techniques to minimize environmental impact and ensure land reclamation. In contrast, rare earth element extraction typically involves more selective overburden removal, demanding advanced geochemical analysis to manage waste and reduce toxic runoff.

Acid Mine Drainage (AMD)

Coal mining frequently generates Acid Mine Drainage (AMD) due to the oxidation of sulfide minerals like pyrite, leading to acidic, metal-rich water that severely impacts surrounding ecosystems. In contrast, rare earth element extraction involves less sulfide mineral disturbance but can still produce AMD when sulfide-bearing ores are processed, necessitating careful waste management to mitigate environmental contamination.

Coal Seam Gasification

Coal Seam Gasification (CSG) uniquely converts coal into synthetic gas directly underground, offering a cleaner alternative to traditional coal mining by reducing surface disturbance and emissions. Rare earth element extraction involves complex processes to isolate valuable minerals critical for electronics, yet CSG presents an innovative energy source from coal seams with lower environmental impact compared to both conventional coal mining and rare earth mineral recovery.

Rare Earth Ore Beneficiation

Rare earth ore beneficiation involves specialized processes such as gravity separation, magnetic separation, and flotation to concentrate valuable minerals from low-grade ores, contrasting with coal mining's relatively simpler extraction and washing methods. Advanced beneficiation techniques enhance the purity and yield of rare earth elements, crucial for high-tech applications and renewable energy technologies.

Critical Minerals Supply Chain

Coal mining primarily targets abundant carbon-rich deposits for energy production, generating substantial environmental challenges, whereas rare earth element extraction focuses on strategically vital minerals critical for high-tech and renewable energy industries, emphasizing the security and sustainability of the critical minerals supply chain. Efficient sourcing of rare earth elements is essential to reduce dependency on geopolitical hotspots and support advanced technologies, contrasting with coal's declining role in global energy transitions.

Tailings Reprocessing

Tailings reprocessing in coal mining primarily targets the recovery of residual coal fines and minimizes environmental hazards by stabilizing heavy metals and reducing acid mine drainage risks. In rare earth element extraction, tailings reprocessing focuses on extracting valuable lanthanides from discarded residues, addressing both resource efficiency and mitigating radioactive waste exposure.

Environmental Impact Quotient (EIQ)

Coal mining generates substantial Environmental Impact Quotient (EIQ) values due to high greenhouse gas emissions, water pollution, and habitat destruction, while rare earth element extraction often results in toxic waste and radioactive byproducts, leading to soil and water contamination. Despite lower volume extraction, rare earth mining's EIQ remains significant because of the complex chemical processing and acid wastewater involved.

Solvent Extraction Electrowinning (SX-EW)

Solvent Extraction Electrowinning (SX-EW) is a pivotal hydrometallurgical technique predominantly utilized in rare earth element extraction, offering selective metal recovery and lower environmental impact compared to traditional coal mining methods. Unlike coal extraction, which relies on physical mining and combustion with high carbon emissions, SX-EW enables efficient separation and electrochemical recovery of rare earth metals from dilute solutions, enhancing resource sustainability and economic viability.

Selective Leaching

Selective leaching in coal mining targets specific mineral components such as sulfur compounds to minimize environmental impact and improve fuel quality, while in rare earth element extraction, it enables efficient separation of valuable elements like neodymium and dysprosium from complex ore matrices. Optimizing leaching parameters, including pH and reagent concentration, enhances recovery rates and reduces waste generation in both mining processes.

Circular Economy in Mining

Coal mining generates significant waste and environmental degradation, whereas rare earth element extraction emphasizes resource recovery and material reuse, aligning more closely with circular economy principles by promoting sustainable supply chains and minimizing ecological impact. Implementing circular economy strategies in rare earth mining enhances recycling processes, reduces reliance on virgin materials, and supports long-term resource efficiency critical for green technologies.

Coal mining vs Rare earth element extraction Infographic

industrydif.com

industrydif.com