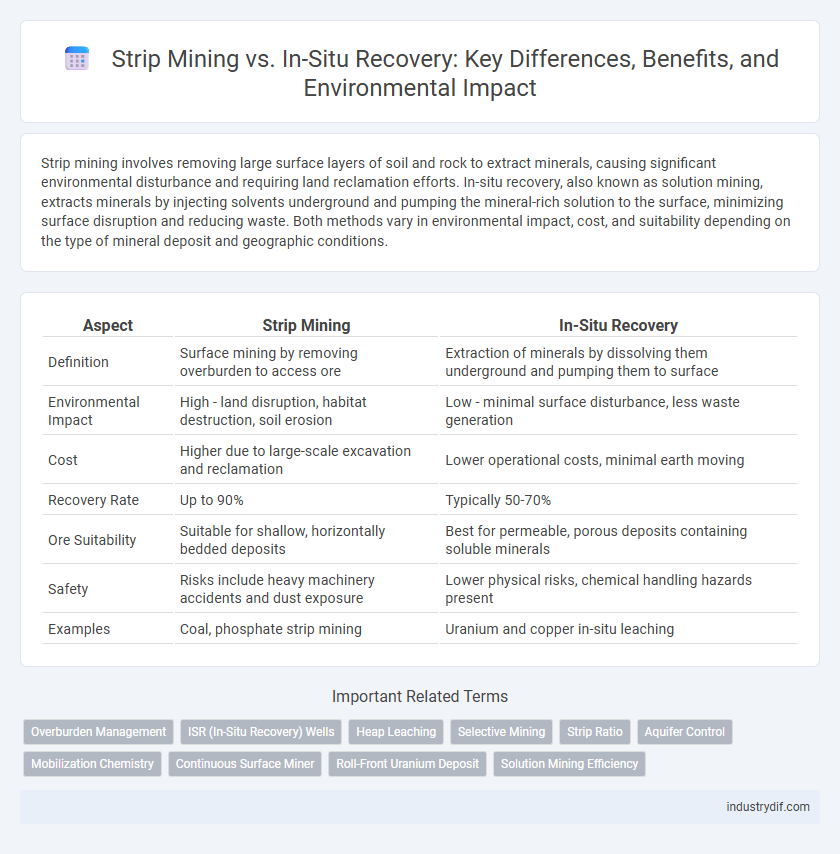

Strip mining involves removing large surface layers of soil and rock to extract minerals, causing significant environmental disturbance and requiring land reclamation efforts. In-situ recovery, also known as solution mining, extracts minerals by injecting solvents underground and pumping the mineral-rich solution to the surface, minimizing surface disruption and reducing waste. Both methods vary in environmental impact, cost, and suitability depending on the type of mineral deposit and geographic conditions.

Table of Comparison

| Aspect | Strip Mining | In-Situ Recovery |

|---|---|---|

| Definition | Surface mining by removing overburden to access ore | Extraction of minerals by dissolving them underground and pumping them to surface |

| Environmental Impact | High - land disruption, habitat destruction, soil erosion | Low - minimal surface disturbance, less waste generation |

| Cost | Higher due to large-scale excavation and reclamation | Lower operational costs, minimal earth moving |

| Recovery Rate | Up to 90% | Typically 50-70% |

| Ore Suitability | Suitable for shallow, horizontally bedded deposits | Best for permeable, porous deposits containing soluble minerals |

| Safety | Risks include heavy machinery accidents and dust exposure | Lower physical risks, chemical handling hazards present |

| Examples | Coal, phosphate strip mining | Uranium and copper in-situ leaching |

Introduction to Strip Mining and In-Situ Recovery

Strip mining involves the large-scale removal of surface layers to access underlying mineral deposits, significantly impacting land and ecosystems. In-situ recovery extracts minerals by injecting solutions directly into the deposit, minimizing surface disturbance and reducing environmental footprint. Both methods target efficient mineral extraction but differ markedly in operational impact and site rehabilitation requirements.

Definitions and Core Principles

Strip mining involves the removal of large surface layers to extract coal or minerals, emphasizing open excavation and disruption of the overburden. In-situ recovery, also known as in-situ leaching, extracts minerals by injecting solvents into underground deposits to dissolve resources without extensive surface disturbance. The core principle of strip mining relies on direct access to ore deposits by stripping surface layers, while in-situ recovery leverages chemical processes and groundwater flow to mobilize minerals for extraction.

Geological Conditions Favoring Each Method

Strip mining is most effective in areas with layered sedimentary deposits near the surface, where ore bodies are relatively horizontal and extend over large, shallow areas. In-situ recovery requires permeable rock formations, such as sandstone, with sufficient porosity and permeability to allow the circulation of leaching solutions without contaminating surrounding aquifers. Geological stability and the presence of confined aquifers are critical for in-situ recovery to prevent environmental hazards and ensure efficient extraction.

Extraction Processes: Step-by-Step Comparison

Strip mining involves the physical removal of surface layers to access mineral deposits through sequential stripping, drilling, blasting, and hauling. In-situ recovery employs chemical solvents injected into the ore body to dissolve minerals, followed by pumping the solution to the surface for extraction, minimizing surface disturbance. While strip mining requires extensive land alteration and waste management, in-situ recovery offers a more environmentally conservative approach with precise chemical control.

Environmental Impact Assessment

Strip mining causes significant land disturbance and habitat destruction, leading to soil erosion and water pollution from runoff. In-situ recovery minimizes surface disruption by injecting chemical solutions to dissolve minerals underground, reducing landscape alteration but posing risks of groundwater contamination. Environmental Impact Assessment must analyze soil, water, and ecosystem effects, emphasizing long-term remediation and monitoring strategies for both methods.

Economic Efficiency and Cost Analysis

Strip mining generally incurs higher upfront capital costs due to extensive land clearing, excavation, and waste management compared to in-situ recovery, which relies on chemical solutions injected underground, reducing surface disruption and operational expenses. In-situ recovery offers greater economic efficiency in suitable deposits by minimizing labor, equipment, and reclamation costs, though it demands favorable geochemical conditions to optimize extraction rates and reduce reagent consumption. Cost analysis reveals that while strip mining can yield higher immediate ore volumes, in-situ recovery's lower environmental remediation expenses and continuous production cycles enhance long-term profitability in specific mineral deposits.

Resource Recovery and Yield Optimization

Strip mining enables high resource recovery by exposing extensive ore deposits for direct extraction, maximizing yield through surface-level accessibility and efficient material removal. In-situ recovery optimizes yield by dissolving minerals underground and pumping solutions to the surface, minimizing environmental disruption and allowing targeted extraction of valuable ores. Resource recovery in strip mining tends to be higher but involves greater land disturbance, whereas in-situ recovery offers enhanced sustainability with comparatively lower recovery rates.

Technological Innovations Driving Each Method

Strip mining leverages advanced earth-moving equipment and automated systems to enhance excavation efficiency and environmental monitoring, significantly reducing surface disruption. In-situ recovery employs cutting-edge chemical injection techniques and real-time sensor technology to extract minerals with minimal surface disturbance, optimizing resource retrieval and groundwater protection. Innovations such as remote sensing and AI-driven process control are pivotal in improving safety, precision, and sustainability in both mining methods.

Regulatory and Compliance Considerations

Strip mining faces stringent regulatory scrutiny due to extensive land disturbance and environmental impact, requiring permits under the Surface Mining Control and Reclamation Act (SMCRA) and adherence to reclamation plans. In-situ recovery (ISR) involves complex groundwater protection measures, necessitating compliance with the Safe Drinking Water Act (SDWA) and state-specific aquifer restoration standards to prevent contamination. Both methods demand thorough environmental impact assessments and ongoing monitoring to meet federal and state mining regulations.

Future Trends in Mining Techniques

Future trends in mining techniques emphasize environmental sustainability and cost efficiency, with strip mining evolving to incorporate advanced land rehabilitation technologies to minimize ecological impact. In-situ recovery (ISR) is gaining momentum due to its lower surface disturbance and reduced water usage, supported by innovations in solvent chemistry and monitoring systems that enhance resource extraction accuracy. Emerging methods are expected to blend remote sensing, automation, and real-time data analytics to optimize both strip mining and ISR operations, driving higher productivity and environmental compliance.

Related Important Terms

Overburden Management

Strip mining requires extensive overburden removal, creating large waste piles that demand careful management to prevent environmental degradation, whereas in-situ recovery minimizes surface disturbance by extracting minerals directly through chemical solutions, significantly reducing overburden handling and ecological impact. Efficient overburden management in strip mining involves reclamation techniques and erosion control, while in-situ methods focus on groundwater protection and controlling leachate migration.

ISR (In-Situ Recovery) Wells

ISR wells enable the extraction of minerals by injecting leaching solutions directly into ore deposits, minimizing surface disruption compared to traditional strip mining that removes large soil layers. This method reduces environmental impact and operational costs while allowing targeted recovery of valuable minerals such as uranium and copper.

Heap Leaching

Heap leaching in strip mining involves extracting minerals by stacking ore and applying chemical solutions, enabling recovery of metals like gold and copper with lower operational costs and surface disruption compared to in-situ recovery, which dissolves minerals directly underground using injected leaching solutions. The environmental impact of heap leaching is significant due to potential leachate leakage, while in-situ recovery minimizes surface disturbance but poses risks of groundwater contamination.

Selective Mining

Strip mining allows for selective extraction by removing specific surface layers to access high-grade ore, minimizing waste material compared to bulk excavation. In-situ recovery targets ore bodies through precise injection and extraction techniques, enabling selective mining with reduced environmental disturbance and improved resource efficiency.

Strip Ratio

Strip mining requires a low strip ratio to maximize economic feasibility, as excessive waste removal increases operational costs and environmental impact. In contrast, in-situ recovery bypasses traditional strip ratio concerns by extracting minerals directly from ore deposits through fluid injection, minimizing surface disturbance and waste generation.

Aquifer Control

Strip mining disrupts aquifer systems by removing overlying soil and rock, leading to potential contamination and altered groundwater flow, whereas in-situ recovery minimizes surface disturbance by injecting solvents underground to dissolve minerals, allowing better aquifer control through limited permeability alteration and reduced surface water infiltration. Effective aquifer management in strip mining requires extensive dewatering and containment measures, while in-situ recovery relies on precise control of injection pressures and chemical reagents to maintain aquifer integrity.

Mobilization Chemistry

Strip mining utilizes physical removal of overburden and ore, relying heavily on mechanical and chemical processes to mobilize minerals, whereas in-situ recovery (ISR) involves injection of chemical solutions such as sulfuric acid or alkaline lixiviants to dissolve and extract minerals directly within the ore body, optimizing mobilization chemistry by minimizing surface disturbance. The chemical reagents in ISR promote selective mineral solubilization, improving recovery rates and reducing environmental impact compared to the more invasive physical extraction methods of strip mining.

Continuous Surface Miner

Continuous Surface Miner technology offers a more efficient and environmentally friendly alternative to traditional strip mining by selectively extracting minerals with minimal land disruption. In-situ recovery processes, while less invasive, often lag behind in production rates and are limited by ore deposit characteristics compared to the high-capacity, continuous operation of surface miners.

Roll-Front Uranium Deposit

Strip mining involves the excavation of overburden to access uranium deposits directly, causing significant land disturbance, whereas in-situ recovery (ISR) injects lixiviants into roll-front uranium deposits to dissolve and extract minerals underground with minimal surface impact. Roll-front uranium deposits, characterized by their crescent-shaped mineralized zones in permeable sandstone formations, are particularly suited for ISR due to their permeability and groundwater flow dynamics, enabling efficient and environmentally preferable uranium extraction compared to conventional strip mining.

Solution Mining Efficiency

Strip mining involves removing large surface layers to access minerals, resulting in significant land disturbance and lower overall efficiency due to extensive excavation and waste material management. In-situ recovery achieves higher solution mining efficiency by injecting solvents directly into ore deposits, minimizing surface impact and enabling continuous mineral extraction with reduced environmental footprint.

Strip mining vs In-situ recovery Infographic

industrydif.com

industrydif.com