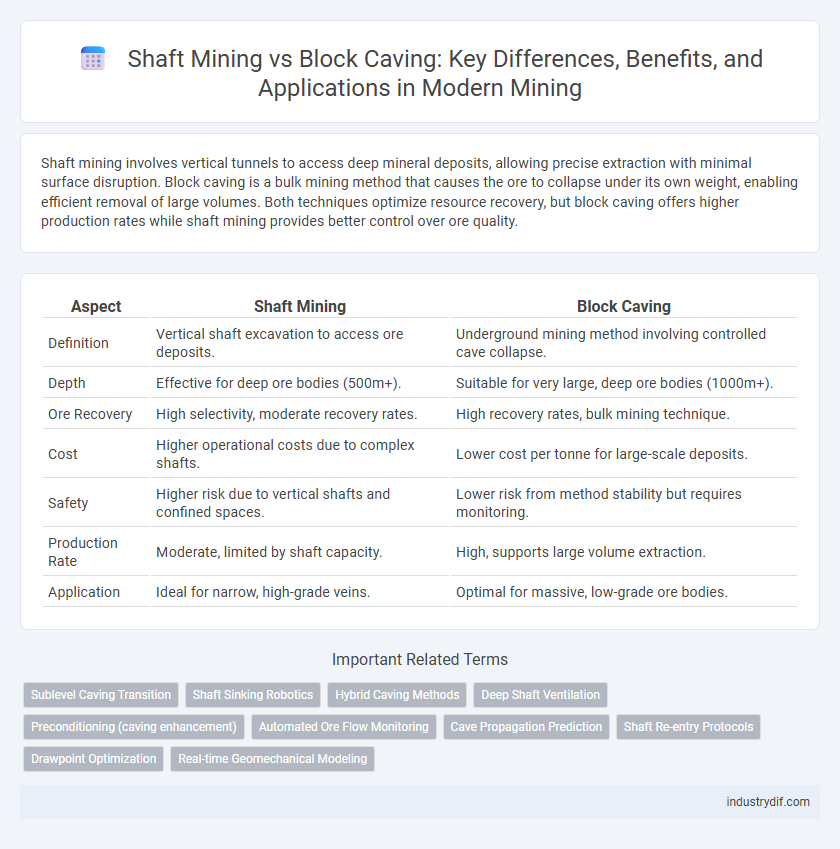

Shaft mining involves vertical tunnels to access deep mineral deposits, allowing precise extraction with minimal surface disruption. Block caving is a bulk mining method that causes the ore to collapse under its own weight, enabling efficient removal of large volumes. Both techniques optimize resource recovery, but block caving offers higher production rates while shaft mining provides better control over ore quality.

Table of Comparison

| Aspect | Shaft Mining | Block Caving |

|---|---|---|

| Definition | Vertical shaft excavation to access ore deposits. | Underground mining method involving controlled cave collapse. |

| Depth | Effective for deep ore bodies (500m+). | Suitable for very large, deep ore bodies (1000m+). |

| Ore Recovery | High selectivity, moderate recovery rates. | High recovery rates, bulk mining technique. |

| Cost | Higher operational costs due to complex shafts. | Lower cost per tonne for large-scale deposits. |

| Safety | Higher risk due to vertical shafts and confined spaces. | Lower risk from method stability but requires monitoring. |

| Production Rate | Moderate, limited by shaft capacity. | High, supports large volume extraction. |

| Application | Ideal for narrow, high-grade veins. | Optimal for massive, low-grade ore bodies. |

Introduction to Shaft Mining and Block Caving

Shaft mining involves vertical excavation to access deep ore deposits, utilizing shafts for transportation of miners and materials, ensuring precise control over ore extraction. Block caving is a cost-effective underground mining method that exploits gravity to collapse ore bodies by undercutting, allowing fragmented ore to be collected from drawpoints. Both techniques target large, low-grade ore bodies, but shaft mining suits narrow, high-grade veins, while block caving excels in massive, massive sulfide or porphyry deposits.

Overview of Shaft Mining Techniques

Shaft mining techniques involve vertical or near-vertical tunnels that provide access to underground mineral deposits, facilitating efficient extraction of ores. Common shaft mining methods include vertical shafts, winzes, and raises, designed to optimize ventilation, material transport, and worker movement. These techniques support targeted extraction in deep, narrow ore bodies with precise control over mining operations and safety protocols.

Fundamentals of Block Caving Methods

Block caving is an underground mining method that exploits the natural fracture of large ore bodies by undermining them, allowing the ore to collapse under its own weight. This technique differs from traditional shaft mining, where ore is extracted by drilling and blasting along vertical shafts; block caving relies on gravity to facilitate continuous ore extraction, making it highly efficient for low-grade, massive ore deposits. Key factors in block caving include ground control, draw control, and cave management to optimize ore recovery and maintain safety.

Geological Suitability: Shaft Mining vs Block Caving

Shaft mining is ideal for deep, narrow ore bodies with high-grade veins, where vertical access minimizes material handling and geological complexity allows stable shaft construction. Block caving suits massive, low-grade ore deposits with weak rock structures, relying on controlled subsidence and gravity to extract large volumes efficiently. Geological stability and ore body morphology directly influence the selection between shaft mining and block caving methods.

Ore Body Characteristics and Method Selection

Shaft mining is preferred for narrow, steeply dipping ore bodies with high-value minerals where precise access and ventilation control are critical, while block caving suits large, low-grade, massive ore bodies with massive or tabular geometry allowing for gravity-assisted fragment caving. The selection between shaft mining and block caving depends on factors such as ore body depth, shape, rock stability, and economic feasibility of extraction. ore body characteristics like thickness, dip angle, and mineral distribution directly influence the efficiency of either method to optimize production and minimize costs.

Equipment and Infrastructure Requirements

Shaft mining demands extensive vertical infrastructure including headframes, hoists, and ventilation shafts to support deep ore extraction and personnel transport. Block caving relies on a network of undercut tunnels, drawbells, and haulage systems designed for large-scale ore collapse and gravity flow, reducing reliance on vertical lifts. Equipment in block caving emphasizes continuous loaders and conveyor systems, while shaft mining utilizes skips and cages for ore and worker movement.

Safety Considerations in Shaft Mining and Block Caving

Shaft mining maintains a higher safety level by providing controlled access points and easier emergency evacuation routes, minimizing the risk of accidents related to ventilation and rockfalls. Block caving presents increased risks due to large-scale ground subsidence and fragment instability, requiring advanced monitoring systems and stringent ground control measures. Effective safety management in both methods relies on continuous risk assessment and implementation of robust engineering controls to protect miners.

Environmental Impact: Comparing Both Methods

Shaft mining generates significant surface disruption and waste rock disposal challenges, leading to habitat fragmentation and potential groundwater contamination. Block caving, while causing substantial subsidence, often results in lower surface disturbance and reduced tailings production due to its method of breaking ore underground. Evaluating environmental impacts requires considering factors like land use, water management, and emissions specific to each technique's operational scale and geology.

Cost and Production Efficiency Analysis

Shaft mining typically incurs higher upfront capital costs due to extensive infrastructure and labor demands, whereas block caving offers lower operational expenses by enabling bulk extraction through gravity-induced fragmentation. Production efficiency in shaft mining is limited by slower ore removal rates and restricted ore body size, while block caving achieves higher throughput and more continuous production streams, significantly reducing per-ton extraction costs. Quantitative analyses show block caving can improve production efficiency by up to 30% and lower cost per ton by approximately 20% compared to traditional shaft mining methods.

Future Trends in Underground Mining Techniques

Shaft mining continues to evolve with advanced ventilation systems and automation technologies enhancing safety and productivity in deep ore extraction. Block caving is rapidly gaining traction due to its cost-efficiency and ability to exploit low-grade ore bodies through controlled subsidence and large-scale mechanization. Future trends emphasize integrating AI-driven monitoring and sustainable energy solutions to optimize underground mining operations and reduce environmental impact.

Related Important Terms

Sublevel Caving Transition

Sublevel caving enables a more controlled and efficient transition from traditional shaft mining to block caving by utilizing horizontal development to fragment ore, reducing the need for extensive shaft infrastructure. This method enhances safety and productivity by allowing gradual ore extraction while maintaining ground stability during the sublevel caving transition phase.

Shaft Sinking Robotics

Shaft sinking robotics revolutionizes shaft mining by automating excavation, improving safety, and accelerating project timelines compared to traditional block caving techniques. Advanced robotic systems enable precise, remote-controlled operations in deep, hazardous environments, reducing human exposure and enhancing efficiency in vertical mine development.

Hybrid Caving Methods

Hybrid caving methods integrate shaft mining's precision with block caving's cost efficiency to enhance ore extraction from large, deep deposits, optimizing both production rates and operational safety. These techniques leverage controlled fragmentation and improved ventilation systems to maximize resource recovery while minimizing subsidence and environmental impact.

Deep Shaft Ventilation

Deep shaft ventilation in shaft mining relies on vertical ventilation shafts and powerful fans to maintain airflow, ensuring adequate oxygen levels and removing hazardous gases from deep underground. Block caving, by contrast, utilizes natural rock fractures for air circulation, often requiring fewer ventilation shafts but more extensive management of airflow paths to control dust and gas in large cavernous spaces.

Preconditioning (caving enhancement)

Preconditioning in shaft mining involves controlled blasting and hydraulic fracturing to enhance rock fragmentation and facilitate safer ore extraction, while block caving relies on systematic undercutting and preconditioning techniques to induce natural cave propagation and optimize cave flow. Effective preconditioning in block caving accelerates caving response and improves ore recovery by reducing draw control issues and mitigating seismic risks.

Automated Ore Flow Monitoring

Shaft mining utilizes vertical tunnels for ore extraction, while block caving involves controlled collapse of ore bodies to access materials more efficiently. Automated ore flow monitoring systems enhance both methods by providing real-time data on ore movement, improving operational safety and optimizing resource recovery.

Cave Propagation Prediction

Shaft mining relies on vertical tunnels to access ore bodies, while block caving involves controlled cave propagation to fragment ore for extraction, making accurate cave propagation prediction critical for operational safety and efficiency. Advanced geotechnical modeling and monitoring techniques, including microseismic analysis and discrete element methods, enhance the prediction of cave behavior in block caving, reducing subsidence risks compared to traditional shaft mining.

Shaft Re-entry Protocols

Shaft re-entry protocols in shaft mining require rigorous ventilation checks, gas monitoring, and structural integrity assessments to ensure miner safety during access and egress stages. In comparison, block caving involves continuous access through drift systems, making shaft re-entry protocols less frequent but still critical for maintenance and emergency evacuation procedures.

Drawpoint Optimization

Drawpoint optimization in shaft mining involves precise control of ore extraction through vertical shafts to maximize resource recovery and minimize dilution. In block caving, optimizing drawpoints focuses on managing cave propagation and draw schedules to enhance ore flow, improve fragmentation, and increase overall production efficiency.

Real-time Geomechanical Modeling

Real-time geomechanical modeling in shaft mining provides continuous monitoring of stress and deformation within vertical excavation shafts, enhancing safety and operational efficiency by enabling immediate responses to ground behavior changes. In block caving, real-time models predict cave propagation and subsidence patterns, optimizing ore recovery and minimizing surface impact through dynamic simulation of rock mass movement.

Shaft mining vs Block caving Infographic

industrydif.com

industrydif.com