Drill and blast mining involves using explosives to fragment rock, enabling efficient extraction but generating significant vibrations and dust. Electric mines prioritize battery-powered equipment and electric drilling, reducing emissions and noise for a cleaner, safer environment. Transitioning to electric mining technologies enhances sustainability and operational efficiency while minimizing environmental impact.

Table of Comparison

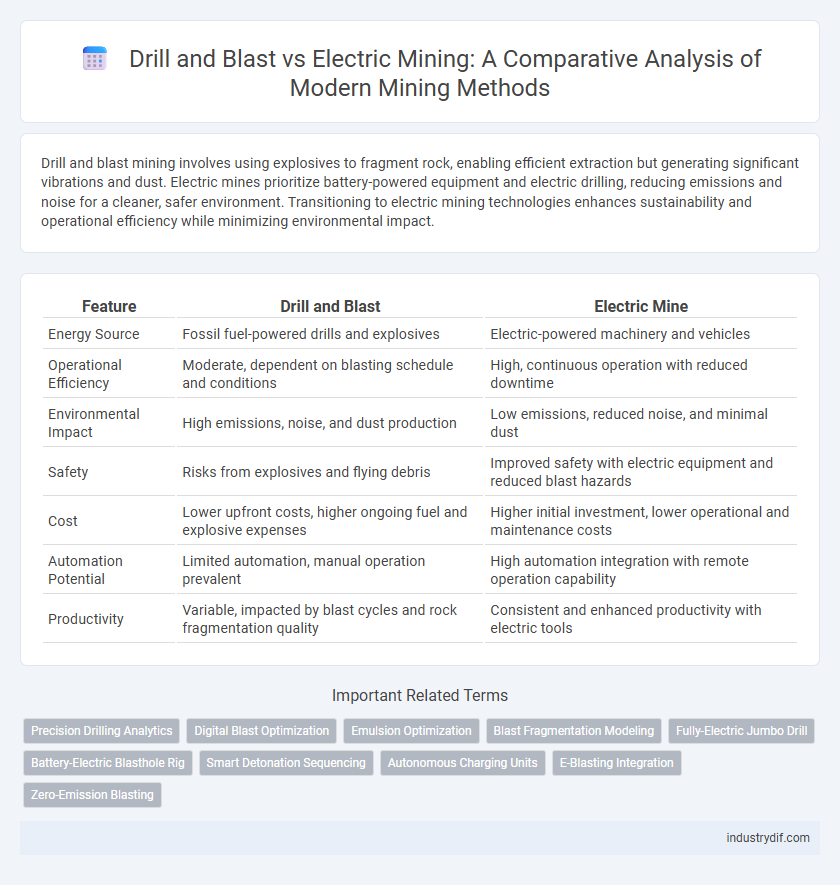

| Feature | Drill and Blast | Electric Mine |

|---|---|---|

| Energy Source | Fossil fuel-powered drills and explosives | Electric-powered machinery and vehicles |

| Operational Efficiency | Moderate, dependent on blasting schedule and conditions | High, continuous operation with reduced downtime |

| Environmental Impact | High emissions, noise, and dust production | Low emissions, reduced noise, and minimal dust |

| Safety | Risks from explosives and flying debris | Improved safety with electric equipment and reduced blast hazards |

| Cost | Lower upfront costs, higher ongoing fuel and explosive expenses | Higher initial investment, lower operational and maintenance costs |

| Automation Potential | Limited automation, manual operation prevalent | High automation integration with remote operation capability |

| Productivity | Variable, impacted by blast cycles and rock fragmentation quality | Consistent and enhanced productivity with electric tools |

Overview: Drill and Blast vs Electric Mine

Drill and Blast methods dominate traditional mining by using explosives to fracture rock, enabling efficient large-scale extraction but generating significant dust, vibrations, and emissions. Electric mine technology integrates battery-powered equipment and electric drills, minimizing environmental impact, lowering operational costs, and reducing underground air pollution. Transitioning to electric mines enhances safety and sustainability while promoting energy efficiency and reducing dependence on fossil fuels.

Technological Advances: Traditional vs Modern Mining

Drill and Blast techniques rely on explosives and mechanical drilling, characterized by high energy consumption and significant environmental impact. Electric mines leverage advanced battery technology, automation, and electric machinery, reducing emissions and operational noise. Modern mining integrates IoT and AI, optimizing electric equipment efficiency and enhancing safety compared to traditional drilling methods.

Efficiency and Productivity Comparison

Drill and blast methods in mining typically achieve higher fragmentation control, leading to improved ore extraction efficiency compared to early-stage electric mining technologies. Electric mining equipment, while offering enhanced energy efficiency and reduced operational emissions, currently faces challenges in matching the productivity rates of conventional drill and blast operations. Advancements in electric mine automation and battery technology are critical to closing this productivity gap and enhancing overall mining efficiency.

Environmental Impact: Blasting vs Electrification

Drill and blast mining generates significant air and noise pollution, releasing dust, vibrations, and greenhouse gases from explosives, which contribute to environmental degradation. In contrast, electrification in mining reduces emissions by eliminating explosive use and enabling the adoption of cleaner, battery-powered machinery, leading to lower carbon footprints. Electric mines also improve air quality and minimize ground vibrations, promoting safer, more sustainable mining operations with reduced ecological impact.

Safety Considerations in Both Methods

Drill and blast mining involves handling explosives, posing risks such as flyrock, dust inhalation, and ground vibrations that require strict safety protocols and specialized training. Electric mining methods eliminate explosive hazards, reducing risks of accidental detonations and improving air quality by producing no blast fumes, thereby enhancing worker safety in underground operations. Both techniques demand rigorous safety management, but electric mining offers inherent advantages in minimizing occupational health hazards and environmental impact.

Cost Analysis: CapEx and OpEx

Drill and Blast mining involves significant CapEx due to equipment acquisition and explosives, while OpEx includes labor, maintenance, and explosive costs. Electric mines require high initial CapEx for infrastructure like electric vehicles and charging stations but benefit from lower OpEx through reduced fuel and maintenance expenses. Cost analysis reveals electric mining may offer long-term savings by minimizing operational expenses and improving energy efficiency.

Energy Consumption and Power Sources

Drill and blast mining relies heavily on diesel-powered machinery and explosives, resulting in high energy consumption and significant carbon emissions. In contrast, electric mines utilize battery-electric vehicles and equipment powered by renewable energy or grid electricity, substantially reducing fossil fuel dependence and operational energy costs. Transitioning to electric mine operations supports sustainable mining practices by lowering greenhouse gas emissions while maintaining efficient productivity.

Mineral Recovery Rates and Ore Selectivity

Drill and blast techniques typically achieve moderate mineral recovery rates due to fragmentation variability, which can cause dilution and ore loss, reducing overall selectivity. Electric mining methods, such as electric rope shovels combined with precision extraction, enhance ore selectivity by minimizing dilution through controlled excavation and real-time monitoring. Improved ore selectivity in electric mining leads to higher mineral recovery rates, optimizing resource utilization and reducing processing costs.

Regulatory Compliance and Future Trends

Drill and blast mining operations must adhere to strict regulatory compliance standards regarding explosive handling, dust, and vibration control, which increasingly push for enhanced safety protocols. Electric mines offer a promising alternative with lower emissions and simplified regulatory compliance due to reduced environmental impact and noise pollution. Future trends indicate a shift toward electric mining technologies driven by stringent environmental regulations and global decarbonization goals.

Workforce Skills and Training Evolution

The transition from drill and blast techniques to electric mining demands a significant evolution in workforce skills, emphasizing proficiency in advanced automation, electric machinery maintenance, and digital monitoring systems. Training programs are increasingly incorporating virtual reality simulations and data analytics to equip miners with the capabilities required for electric mine operations. This shift enhances workforce adaptability while reducing operational risks and improving safety standards in modern mining environments.

Related Important Terms

Precision Drilling Analytics

Precision drilling analytics in drill and blast mining enhance fragmentation control and reduce ore dilution rates by leveraging real-time data and machine learning algorithms. Electric mines further optimize these analytics by integrating advanced sensors with electric drilling rigs, improving energy efficiency and minimizing environmental impact while maintaining drilling accuracy.

Digital Blast Optimization

Digital Blast Optimization leverages advanced sensors and AI algorithms to enhance drilling precision and explosive placement, significantly improving fragmentation and reducing environmental impact compared to traditional Drill and Blast methods. Electric Mine technologies integrate these digital solutions to enable real-time monitoring and adaptive blast designs, increasing operational efficiency and safety in mining operations.

Emulsion Optimization

Emulsion optimization in drill and blast mining enhances explosive energy efficiency, improving fragmentation and reducing ground vibration compared to traditional ANFO-based blasting agents. Electric mines leverage controlled energy use with electric drilling and blasting systems, optimizing emulsion formulations to minimize environmental impact and increase safety through precise detonation timing and reduced toxic gas emissions.

Blast Fragmentation Modeling

Blast fragmentation modeling in drill and blast methods plays a critical role in optimizing fragmentation size, improving mucking efficiency, and reducing downstream processing costs, with models based on parameters like explosive energy, rock properties, and blasthole patterns. Electric mines, leveraging precision blasting and reduced environmental impact, increasingly integrate advanced fragmentation prediction algorithms to enhance safety and productivity while minimizing energy consumption and emissions.

Fully-Electric Jumbo Drill

Fully-electric jumbo drills in mining offer significant advantages over traditional drill and blast methods by reducing emissions, lowering operational costs, and improving safety through eliminating diesel-powered equipment underground. These machines enhance precision and efficiency in tunneling while supporting sustainable mining practices by minimizing environmental impact and improving air quality in mines.

Battery-Electric Blasthole Rig

Battery-electric blasthole rigs reduce greenhouse gas emissions by eliminating diesel combustion, offering a cleaner alternative to traditional drill and blast methods. These rigs enhance operational efficiency through quieter operation, lower ventilation requirements, and reduced maintenance costs compared to conventional diesel-powered equipment.

Smart Detonation Sequencing

Smart detonation sequencing in drill and blast operations enhances precision, reduces vibrations, and improves fragmentation by optimizing the timing between explosive charges. In contrast, electric mines leverage automated control systems for seamless detonation management, increasing safety and efficiency while minimizing environmental impact.

Autonomous Charging Units

Autonomous charging units in electric mines significantly enhance operational efficiency by enabling continuous, hands-free recharging of battery-powered equipment, reducing downtime compared to traditional drill and blast operations reliant on fossil fuel machinery. These units optimize energy management and support sustainable mining practices by integrating smart charging protocols tailored to electric mining vehicles, which are increasingly favored for their low emissions and reduced ventilation needs.

E-Blasting Integration

E-Blasting integration in mining enhances precision and efficiency by synchronizing electric initiation systems with automated drilling rigs, minimizing misfires and reducing environmental impact. This technology streamlines blast sequencing and timing control, leading to improved fragmentation, reduced vibration, and lower operational costs compared to traditional drill and blast techniques.

Zero-Emission Blasting

Zero-emission blasting in electric mines eliminates diesel-powered drill rigs, significantly reducing greenhouse gas emissions and improving air quality underground. Advanced electric drilling and blasting technologies enhance precision and safety while supporting sustainable mining practices aligned with global carbon reduction goals.

Drill and Blast vs Electric Mine Infographic

industrydif.com

industrydif.com