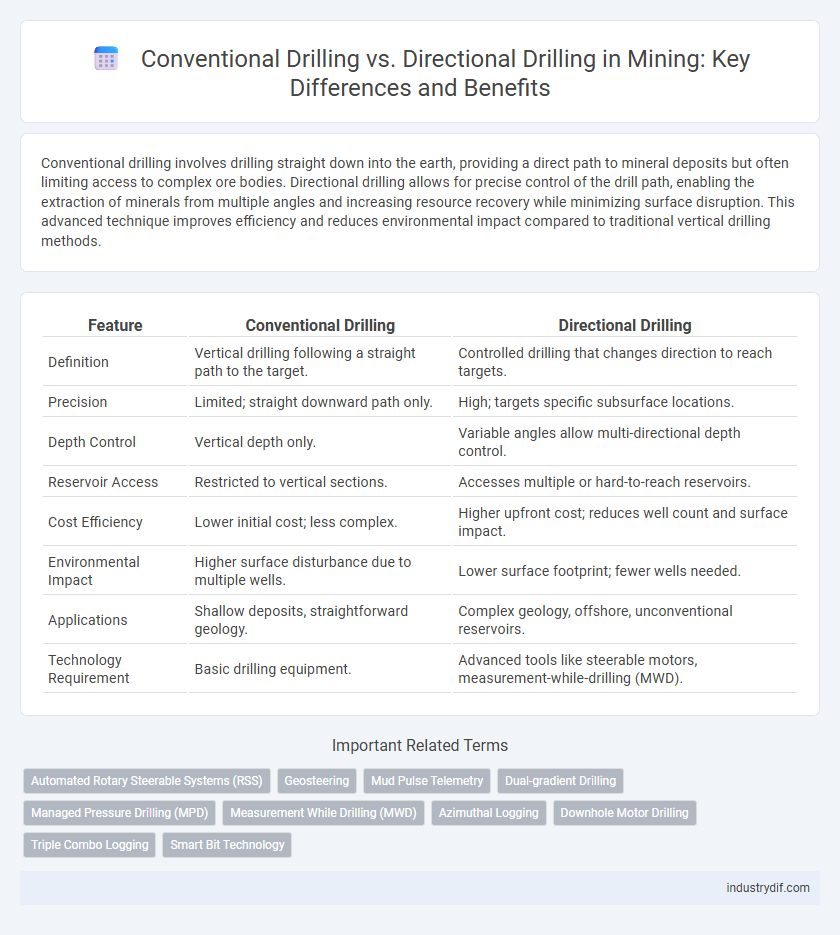

Conventional drilling involves drilling straight down into the earth, providing a direct path to mineral deposits but often limiting access to complex ore bodies. Directional drilling allows for precise control of the drill path, enabling the extraction of minerals from multiple angles and increasing resource recovery while minimizing surface disruption. This advanced technique improves efficiency and reduces environmental impact compared to traditional vertical drilling methods.

Table of Comparison

| Feature | Conventional Drilling | Directional Drilling |

|---|---|---|

| Definition | Vertical drilling following a straight path to the target. | Controlled drilling that changes direction to reach targets. |

| Precision | Limited; straight downward path only. | High; targets specific subsurface locations. |

| Depth Control | Vertical depth only. | Variable angles allow multi-directional depth control. |

| Reservoir Access | Restricted to vertical sections. | Accesses multiple or hard-to-reach reservoirs. |

| Cost Efficiency | Lower initial cost; less complex. | Higher upfront cost; reduces well count and surface impact. |

| Environmental Impact | Higher surface disturbance due to multiple wells. | Lower surface footprint; fewer wells needed. |

| Applications | Shallow deposits, straightforward geology. | Complex geology, offshore, unconventional reservoirs. |

| Technology Requirement | Basic drilling equipment. | Advanced tools like steerable motors, measurement-while-drilling (MWD). |

Introduction to Drilling in Mining

Conventional drilling in mining involves vertical holes drilled straight down to access ore bodies, offering simplicity and cost-effectiveness for shallow deposits. Directional drilling employs precise angles to reach targets with complex geometries or beneath obstacles, enhancing resource recovery and operational flexibility. Choosing the appropriate drilling method depends on geological conditions, project objectives, and cost considerations.

Conventional Drilling: Definition and Process

Conventional drilling in mining involves vertical drilling to extract minerals directly beneath the drilling site, relying on gravity for debris removal and fluid circulation. The process begins with site preparation, followed by the use of rotary drills to penetrate rock formations, and ends with the extraction of core samples or minerals. This method is cost-effective and straightforward but offers limited access to deposits spread horizontally or obstructed by geological structures.

Directional Drilling: Overview and Techniques

Directional drilling in mining allows precise wellbore placement by steering drill bits along predetermined paths, improving access to ore bodies while reducing surface disruption. Techniques such as rotary steerable systems (RSS) and measurement-while-drilling (MWD) tools optimize drilling accuracy and operational efficiency in complex geological formations. This method enhances resource recovery, minimizes environmental impact, and lowers overall extraction costs compared to conventional vertical drilling.

Key Differences Between Conventional and Directional Drilling

Conventional drilling involves vertical wells drilled straight down, primarily targeting a single reservoir directly beneath the rig, which limits access to resources spread horizontally or in complex formations. Directional drilling utilizes advanced technology to steer the drill bit at multiple angles, enabling access to reservoirs located beneath obstacles or extending horizontally across wider areas, maximizing resource extraction efficiency. Key differences include the ability of directional drilling to reach multiple targets from a single site, reduce environmental impact by minimizing surface disturbances, and optimize well placement for enhanced production compared to the traditional vertical approach.

Equipment Used in Both Drilling Methods

Conventional drilling primarily uses vertical drill rigs equipped with rotary drill bits and basic casing systems for straightforward boreholes, emphasizing simplicity and cost-effectiveness. Directional drilling employs sophisticated equipment such as steerable motors, rotary steerable systems, measurement-while-drilling (MWD) tools, and advanced downhole sensors to accurately control borehole trajectory. Both methods rely on mud pumps and drill strings, but directional drilling integrates complex navigation and monitoring technologies to optimize well placement and maximize resource extraction.

Advantages of Conventional Drilling in Mining

Conventional drilling in mining offers simplicity and cost-effectiveness, making it highly suitable for straightforward vertical boreholes and shallow deposit exploration. The method requires less complex equipment and operational expertise, reducing both initial investment and maintenance costs. Its reliability and ease of implementation provide efficient extraction in homogeneous ore bodies with minimal geological complications.

Benefits of Directional Drilling for Resource Extraction

Directional drilling enhances resource extraction by enabling access to multiple underground targets from a single surface location, significantly reducing environmental impact and surface disturbance. Improved well placement accuracy increases hydrocarbon recovery rates and minimizes wasted drilling efforts compared to conventional vertical drilling. This technique also allows for better reservoir management and cost efficiency by optimizing well trajectories to avoid geological hazards and maximize exposure to productive zones.

Limitations and Challenges of Each Drilling Method

Conventional drilling faces limitations such as restricted access to complex ore bodies and increased environmental disruption due to vertical boreholes. Directional drilling, while offering enhanced precision and access to challenging formations, presents challenges including higher operational costs, technical complexity, and increased risk of equipment failure in deviated wells. Both methods require careful consideration of geological conditions and project goals to optimize efficiency and minimize risks in mining operations.

Factors Influencing the Choice of Drilling Technique

The selection between conventional drilling and directional drilling in mining is primarily influenced by geological formations, ore body geometry, and environmental constraints. Conventional drilling suits vertical shafts in stable, uniform strata, while directional drilling excels in accessing complex ore bodies and minimizing surface disturbance. Economic factors, including operational costs and project timeline, also significantly determine the preferred drilling method.

Future Trends in Drilling Technology for the Mining Industry

Future trends in mining drilling technology emphasize automation and precision enhancements in both conventional and directional drilling methods. Advanced sensor integration and real-time data analytics optimize drilling efficiency and reduce operational costs, with directional drilling offering superior trajectory control for complex ore bodies. Emerging technologies such as AI-driven predictive maintenance and robotic drill rigs are set to revolutionize the industry by increasing safety and minimizing environmental impact.

Related Important Terms

Automated Rotary Steerable Systems (RSS)

Automated Rotary Steerable Systems (RSS) in directional drilling enhance precision and efficiency by enabling real-time adjustments to the drill path, significantly reducing non-productive time compared to conventional drilling methods. These systems integrate advanced sensors and control algorithms, optimizing well trajectory and improving reservoir contact while minimizing drilling risks and overall operational costs.

Geosteering

Directional drilling enhances geosteering accuracy by enabling real-time wellbore adjustments to navigate complex ore bodies, unlike conventional drilling which follows a fixed vertical path limiting reservoir access. This technology maximizes mineral extraction efficiency, reduces environmental impact, and improves resource recovery rates in challenging geological formations.

Mud Pulse Telemetry

Mud Pulse Telemetry in directional drilling enables real-time data transmission from the drill bit to the surface, significantly enhancing precision compared to conventional drilling methods that lack such advanced communication. This technology improves directional control and reduces drilling risks by providing continuous downhole measurements critical for navigating complex subsurface formations.

Dual-gradient Drilling

Dual-gradient drilling enhances conventional and directional drilling methods by maintaining two separate mud densities to balance wellbore pressures more effectively, reducing risks of formation damage and blowouts. This technique optimizes drilling efficiency and safety in complex geological formations by precisely controlling wellbore pressure profiles during mining operations.

Managed Pressure Drilling (MPD)

Conventional drilling relies on fixed vertical or near-vertical wells, limiting pressure control and increasing risks of formation damage and blowouts, whereas directional drilling, especially Managed Pressure Drilling (MPD), employs precise pressure management technologies to optimize drilling parameters, enhance wellbore stability, and improve hydrocarbon recovery in complex reservoirs. MPD integrates real-time monitoring and automated pressure control systems, reducing non-productive time and minimizing formation fluid influx by maintaining bottom-hole pressure within narrow margins.

Measurement While Drilling (MWD)

Measurement While Drilling (MWD) technology enhances directional drilling by providing real-time data on wellbore trajectory, enabling precise steering and improved accuracy compared to conventional drilling methods that rely on periodic measurements. Integrating MWD in directional drilling optimizes operational efficiency, minimizes non-productive time, and enhances overall resource extraction in complex geological formations.

Azimuthal Logging

Conventional drilling provides vertical boreholes primarily used for initial resource evaluation, while directional drilling enables precise well placement by altering the borehole trajectory, essential for accessing complex ore bodies. Azimuthal logging enhances directional drilling by offering detailed real-time data on borehole orientation and formation properties, improving accuracy in geological modeling and resource extraction efficiency.

Downhole Motor Drilling

Conventional drilling relies on vertical boreholes for straightforward access to mineral deposits, while directional drilling, enhanced by downhole motor drilling, enables precise steering of the drill bit to reach complex underground targets and maximize resource extraction. Downhole motors use mud flow to power the drill bit independently of the drill string rotation, improving drilling efficiency and reducing deviation in challenging geological formations.

Triple Combo Logging

Triple Combo Logging provides detailed formation evaluation by recording resistivity, porosity, and gamma-ray data, crucial for both conventional and directional drilling in mining exploration. Directional drilling benefits from this data by enabling precise wellbore placement in complex ore bodies, while conventional drilling relies on Triple Combo Logging to assess vertical borehole conditions and optimize extraction strategies.

Smart Bit Technology

Smart Bit Technology in conventional drilling optimizes penetration rates by enhancing bit durability and real-time feedback, reducing downtime and bit wear. In directional drilling, this technology enables precise steering and trajectory control, improving accuracy in complex ore body extraction and minimizing environmental impact.

Conventional drilling vs Directional drilling Infographic

industrydif.com

industrydif.com