Traditional smelting relies heavily on fossil fuels and produces significant greenhouse gas emissions, contributing to environmental degradation. Green metallurgy utilizes innovative processes such as hydrometallurgy and bioleaching to extract metals with lower energy consumption and reduced carbon footprint. This shift promotes sustainable mining practices by minimizing toxic waste and enhancing resource efficiency.

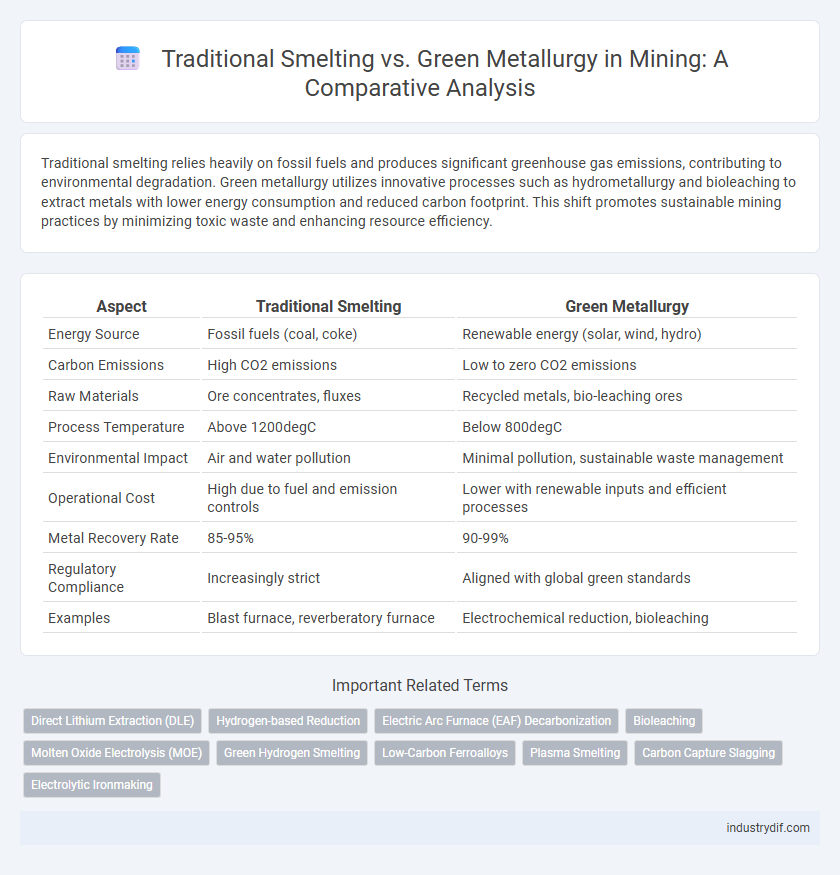

Table of Comparison

| Aspect | Traditional Smelting | Green Metallurgy |

|---|---|---|

| Energy Source | Fossil fuels (coal, coke) | Renewable energy (solar, wind, hydro) |

| Carbon Emissions | High CO2 emissions | Low to zero CO2 emissions |

| Raw Materials | Ore concentrates, fluxes | Recycled metals, bio-leaching ores |

| Process Temperature | Above 1200degC | Below 800degC |

| Environmental Impact | Air and water pollution | Minimal pollution, sustainable waste management |

| Operational Cost | High due to fuel and emission controls | Lower with renewable inputs and efficient processes |

| Metal Recovery Rate | 85-95% | 90-99% |

| Regulatory Compliance | Increasingly strict | Aligned with global green standards |

| Examples | Blast furnace, reverberatory furnace | Electrochemical reduction, bioleaching |

Overview of Traditional Smelting in Mining

Traditional smelting in mining involves the extraction of metals from ores using high-temperature furnaces fueled by coal or coke, resulting in significant greenhouse gas emissions and environmental pollution. This process relies heavily on pyrometallurgical methods, which often produce large quantities of sulfur dioxide and other toxic byproducts, contributing to air and water contamination. Despite its efficiency in metal recovery, traditional smelting faces increasing regulatory pressures due to its carbon footprint and adverse ecological impact.

Environmental Impact of Traditional Smelting

Traditional smelting processes generate significant air pollution, releasing toxic emissions such as sulfur dioxide and heavy metals that contribute to acid rain and respiratory illnesses. These methods also produce hazardous solid waste, contaminating soil and water bodies near mining sites. In contrast, green metallurgy employs cleaner technologies that minimize environmental damage by reducing emissions and promoting resource recycling.

Introduction to Green Metallurgy Technologies

Green metallurgy technologies emphasize eco-friendly extraction and processing methods, reducing harmful emissions and energy consumption compared to traditional smelting. Techniques such as hydrometallurgy and bioleaching utilize aqueous chemistry and microbial processes to recover metals from ores and waste materials with minimal environmental impact. These innovative approaches enhance resource efficiency, support sustainable mining practices, and lower the carbon footprint of metal production.

Key Differences Between Traditional and Green Metallurgy

Traditional smelting relies heavily on fossil fuels and emits significant greenhouse gases, whereas green metallurgy utilizes renewable energy sources and adopts eco-friendly processes to minimize environmental impact. Traditional methods often involve high-temperature operations with substantial waste generation, while green metallurgy emphasizes energy efficiency and waste recycling through advanced technologies like hydrometallurgy and bioleaching. The shift to green metallurgy aligns with global sustainability goals by reducing carbon footprints and promoting circular economy principles within the mining industry.

Energy Consumption: Smelting vs Green Approaches

Traditional smelting methods in mining consume significantly higher energy, often relying on fossil fuels and reaching temperatures above 1500degC, resulting in substantial carbon emissions. Green metallurgy employs innovative techniques such as bioleaching, hydrometallurgy, and microwave-assisted smelting, which operate at lower temperatures and utilize renewable energy sources, drastically reducing energy consumption by up to 60%. These energy-efficient green approaches not only lower operational costs but also minimize the environmental footprint of metal extraction processes.

Emissions and Waste Generation Comparison

Traditional smelting processes generate significantly higher emissions, including sulfur dioxide and heavy metals, contributing to air pollution and acid rain. In contrast, green metallurgy employs advanced technologies such as hydrometallurgy and bioleaching that minimize greenhouse gas emissions and reduce hazardous waste production. These sustainable methods promote energy efficiency and resource recovery, resulting in lower environmental impact and enhanced waste management.

Economic Viability of Green Metallurgy

Green metallurgy demonstrates increasing economic viability through reduced energy consumption and lower emissions, leading to decreased operational costs compared to traditional smelting methods. Advances in renewable energy integration and resource recycling enhance profitability by minimizing raw material waste and regulatory compliance expenses. This shift supports sustainable mining practices while maintaining competitive production costs in the metallurgical industry.

Regulatory Trends in Sustainable Metal Processing

Regulatory trends in sustainable metal processing emphasize reducing environmental impact by promoting green metallurgy techniques over traditional smelting methods. Governments worldwide are enforcing stricter emissions standards and mandating the use of energy-efficient, low-waste technologies such as bioleaching and hydrometallurgy. These policies accelerate the transition to sustainable practices that lower carbon footprints and minimize toxic byproducts in the mining sector.

Case Studies: Green Metallurgy Adoption in Mining

Case studies demonstrate that green metallurgy adoption in mining significantly reduces harmful emissions and energy consumption compared to traditional smelting methods. Notable examples include the implementation of hydrometallurgical processes in Chile's copper mining sector, which decreased sulfur dioxide emissions by over 60%. Pilbara Minerals in Australia integrated green metallurgy techniques, achieving higher metal recovery rates while minimizing environmental impact.

Future Perspectives: Green Metallurgy in Global Mining

Green metallurgy is revolutionizing global mining by significantly reducing carbon emissions and minimizing hazardous waste compared to traditional smelting processes. Innovations such as bioleaching, electrochemical recovery, and low-temperature hydrometallurgy enhance metal extraction efficiency while promoting environmental sustainability. The future of mining prioritizes green metallurgy as a strategic approach to meet stricter regulations and rising demand for eco-friendly resource management.

Related Important Terms

Direct Lithium Extraction (DLE)

Traditional smelting in lithium extraction involves energy-intensive processes with high carbon emissions, whereas Green metallurgy prioritizes eco-friendly techniques like Direct Lithium Extraction (DLE), which uses selective adsorption and ion-exchange methods to recover lithium efficiently from brine with minimal environmental impact. DLE significantly reduces water consumption and waste generation compared to conventional evaporation ponds, aligning with sustainable mining practices and the global push for decarbonization in battery material production.

Hydrogen-based Reduction

Hydrogen-based reduction in green metallurgy significantly lowers carbon emissions compared to traditional smelting by replacing coke and coal with hydrogen as the primary reducing agent. This innovative technique enables the production of direct reduced iron (DRI) with water vapor as the only byproduct, promoting sustainable mining and metal extraction processes.

Electric Arc Furnace (EAF) Decarbonization

Electric Arc Furnace (EAF) technology significantly reduces carbon emissions compared to traditional smelting by utilizing electric energy rather than fossil fuels, enabling more sustainable steel production. Green metallurgy leverages EAF decarbonization through renewable energy integration and advanced scrap recycling, minimizing environmental impact and enhancing resource efficiency in mining operations.

Bioleaching

Bioleaching, a green metallurgy technique, uses microorganisms to extract metals from ores, offering an environmentally friendly alternative to traditional smelting which produces significant air pollution and hazardous waste. This method reduces energy consumption and greenhouse gas emissions while enabling the recovery of metals from low-grade ores that are otherwise uneconomical in conventional smelting processes.

Molten Oxide Electrolysis (MOE)

Traditional smelting processes rely heavily on carbon-based fuels, producing significant CO2 emissions and environmental pollutants, whereas Green metallurgy innovations like Molten Oxide Electrolysis (MOE) offer a carbon-free alternative by directly converting metal oxides into pure metals using electric currents in a molten oxide bath. MOE significantly reduces greenhouse gas emissions and enhances energy efficiency, positioning it as a sustainable advancement in metal extraction technologies.

Green Hydrogen Smelting

Green hydrogen smelting revolutionizes traditional mining by replacing carbon-intensive coke with green hydrogen, drastically reducing CO2 emissions in metal production. This innovative method leverages renewable energy to produce green hydrogen, promoting sustainable and eco-friendly smelting processes in the mining industry.

Low-Carbon Ferroalloys

Traditional smelting relies on coke and coal, producing high carbon emissions, whereas green metallurgy utilizes hydrogen-based reduction and renewable energy sources to synthesize low-carbon ferroalloys. Low-carbon ferroalloys produced through green metallurgy significantly reduce greenhouse gas emissions and support sustainable mining practices essential for the clean energy transition.

Plasma Smelting

Plasma smelting significantly reduces greenhouse gas emissions by utilizing high-temperature plasma torches to efficiently extract metals from ores, contrasting traditional smelting methods that rely on carbon-intensive processes and produce substantial CO2 levels. This green metallurgy technique enhances energy efficiency and allows the recycling of hazardous industrial waste, promoting sustainable mining practices with a lower environmental footprint.

Carbon Capture Slagging

Traditional smelting processes release significant amounts of CO2 and other pollutants, whereas green metallurgy techniques integrate carbon capture slagging to effectively trap carbon emissions within slag byproducts, reducing environmental impact. This method enhances sustainability by converting molten slag into a stable carbon sink, minimizing greenhouse gases compared to conventional smelting.

Electrolytic Ironmaking

Electrolytic ironmaking offers a sustainable alternative to traditional smelting by using electricity to reduce iron ore directly, significantly lowering carbon emissions compared to coal-based blast furnaces. Green metallurgy advances this process by integrating renewable energy sources and innovative electrolytes, enhancing efficiency and reducing environmental impact in iron production.

Traditional smelting vs Green metallurgy Infographic

industrydif.com

industrydif.com