Cut and fill mining involves excavating ore in horizontal slices, with waste material used to fill voids, promoting ground stability and safety in underground operations. Deep sea mining targets mineral-rich deposits on the ocean floor, extracting valuable metals like cobalt, manganese, and nickel while raising concerns about marine ecosystem disruption. Choosing between these methods depends on resource location, environmental impact, and technological feasibility.

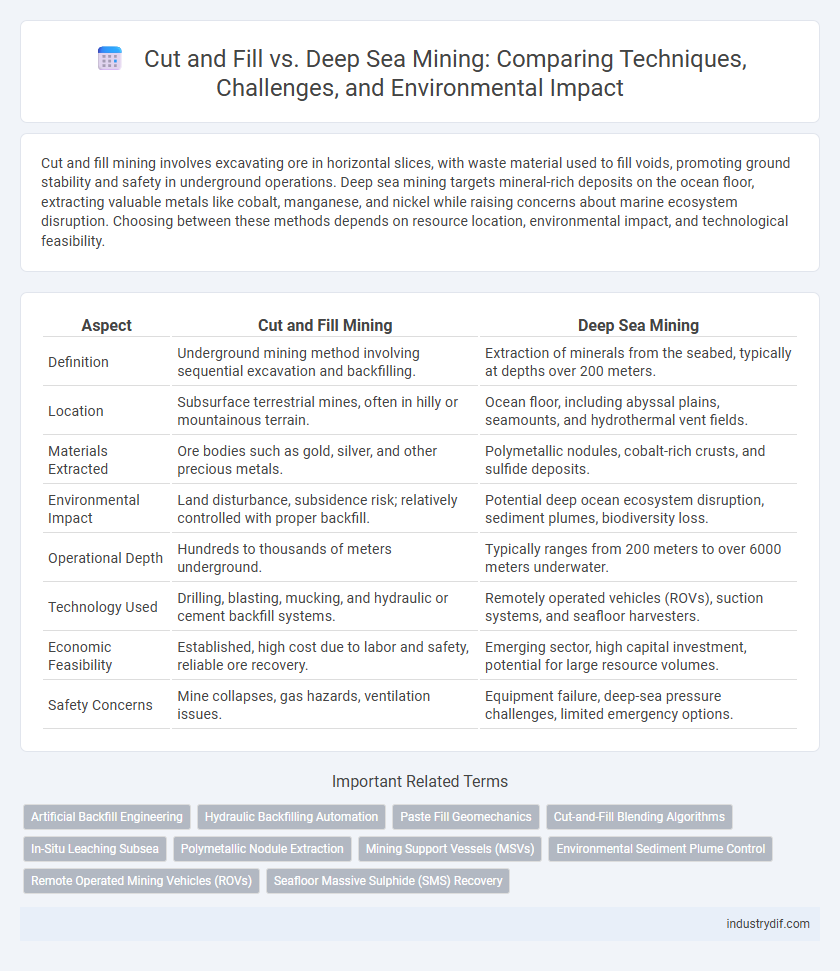

Table of Comparison

| Aspect | Cut and Fill Mining | Deep Sea Mining |

|---|---|---|

| Definition | Underground mining method involving sequential excavation and backfilling. | Extraction of minerals from the seabed, typically at depths over 200 meters. |

| Location | Subsurface terrestrial mines, often in hilly or mountainous terrain. | Ocean floor, including abyssal plains, seamounts, and hydrothermal vent fields. |

| Materials Extracted | Ore bodies such as gold, silver, and other precious metals. | Polymetallic nodules, cobalt-rich crusts, and sulfide deposits. |

| Environmental Impact | Land disturbance, subsidence risk; relatively controlled with proper backfill. | Potential deep ocean ecosystem disruption, sediment plumes, biodiversity loss. |

| Operational Depth | Hundreds to thousands of meters underground. | Typically ranges from 200 meters to over 6000 meters underwater. |

| Technology Used | Drilling, blasting, mucking, and hydraulic or cement backfill systems. | Remotely operated vehicles (ROVs), suction systems, and seafloor harvesters. |

| Economic Feasibility | Established, high cost due to labor and safety, reliable ore recovery. | Emerging sector, high capital investment, potential for large resource volumes. |

| Safety Concerns | Mine collapses, gas hazards, ventilation issues. | Equipment failure, deep-sea pressure challenges, limited emergency options. |

Introduction to Cut and Fill and Deep Sea Mining

Cut and fill mining is a method where ore is extracted in horizontal slices, and the voids are filled with waste rock or tailings to support the surrounding rock, enhancing safety and stability in steeply dipping ore bodies. Deep sea mining involves extracting mineral resources from the ocean floor, targeting polymetallic nodules, sulfides, and cobalt-rich crusts found at depths typically between 1,000 to 6,000 meters. Both techniques address unique geological settings and resource accessibility challenges, with cut and fill suited for underground ore bodies and deep sea mining tapping into largely unexplored seabed mineral deposits.

Cut and Fill Mining: Definition and Key Processes

Cut and fill mining is an underground excavation method where ore is extracted in horizontal slices, and the voids are backfilled with waste materials or tailings to provide ground support and minimize surface subsidence. This technique allows for selective ore removal and is particularly effective in irregular or steeply dipping ore bodies, enhancing safety and stability. Compared to deep sea mining, which targets polymetallic nodules and sulfide deposits on the ocean floor, cut and fill mining is a controlled, terrestrial process optimized for discrete vein or massive ore deposits.

Deep Sea Mining: Overview and Technologies

Deep sea mining involves extracting minerals from the ocean floor, targeting polymetallic nodules, cobalt-rich crusts, and seafloor massive sulfides found at depths ranging from 1,000 to 6,000 meters. Advanced technologies include remotely operated vehicles (ROVs), autonomous underwater vehicles (AUVs), and riser systems that transport mined materials to surface vessels. This method contrasts with cut and fill mining, which is primarily used for underground deposits, emphasizing the unique challenges of underwater extraction such as environmental impact and high operational costs.

Geological Environments: Land vs. Ocean Floor

Cut and fill mining occurs in terrestrial geological environments characterized by stable bedrock or sedimentary formations, allowing selective excavation and backfilling within defined underground stopes. Deep sea mining targets polymetallic nodule-rich or hydrothermal vent-rich ocean floor regions, with complex sediment layers and dynamic marine ecosystems requiring specialized equipment for extraction. The contrasting geological settings of land-based cut and fill mining and ocean floor deep sea mining significantly influence operational methods, environmental impacts, and resource accessibility.

Resource Types Targeted in Cut and Fill and Deep Sea Mining

Cut and fill mining primarily targets hard rock ore bodies such as gold, copper, and lead-zinc deposits located in underground veins and narrow ore zones. Deep sea mining focuses on polymetallic nodules, seafloor massive sulfides, and cobalt-rich crusts found on the ocean floor, rich in metals like manganese, nickel, cobalt, and rare earth elements. These distinctions in resource types influence the mining techniques and environmental considerations unique to each method.

Environmental Impacts: Surface vs. Subsea

Cut and fill mining involves excavation and backfilling on the surface, leading to significant habitat disruption, soil erosion, and potential contamination of local water sources. Deep sea mining disturbs benthic ecosystems, resuspends sediments, and threatens marine biodiversity with long-lasting effects on subsea habitats. While cut and fill impacts are more localized and terrestrial, deep sea mining poses risks to broader, less understood marine environments.

Safety and Risk Management in Both Techniques

Cut and fill mining involves sequential excavation and backfilling, significantly reducing ground instability and improving worker safety through controlled material placement. Deep sea mining poses high risks due to remote operation challenges, potential environmental disturbance, and limited emergency response capabilities, necessitating advanced robotic systems and real-time monitoring for effective risk management. Safety protocols in cut and fill methods are well-established, while deep sea mining requires continuous technological innovation to mitigate hazards inherent in deep ocean conditions.

Economic Considerations and Investment Costs

Cut and fill mining involves higher upfront capital investment due to extensive ground support and excavation requirements, but offers predictable operational costs and reduced environmental remediation expenses. Deep sea mining demands significant initial investment in advanced technology and specialized equipment, with variable costs driven by remote operations, deep-water pressures, and environmental impact mitigation. Economic considerations favor cut and fill mining in regions with accessible ore bodies, while deep sea mining presents high-risk, high-reward opportunities contingent on regulatory frameworks and resource market volatility.

Regulatory and Compliance Challenges

Cut and fill mining faces stringent local regulatory frameworks focused on land rehabilitation and worker safety, requiring detailed environmental impact assessments and continuous monitoring. Deep sea mining is emerging with complex international compliance challenges, involving fragmented jurisdictional authority under the International Seabed Authority and evolving marine biodiversity protection laws. Both mining methods must navigate intricate permitting processes, but deep sea mining demands cutting-edge environmental protocols due to limited scientific understanding of deep-ocean ecosystems.

Future Trends and Innovations in Mining Methods

Cut and fill mining is evolving with automation and remote monitoring to improve safety and efficiency in underground operations, while deep sea mining is leveraging advanced robotic technologies and environmental impact assessments to access polymetallic nodules on the ocean floor. Future trends emphasize sustainable resource extraction through AI-driven predictive analytics and real-time data integration in both methods. Innovations are accelerating the shift towards minimizing ecological footprints and optimizing resource recovery from previously inaccessible or complex deposits.

Related Important Terms

Artificial Backfill Engineering

Cut and fill mining employs artificial backfill engineering using engineered materials such as cemented rock fills to stabilize underground voids and support ore extraction, minimizing surface subsidence. Deep sea mining, in contrast, lacks effective artificial backfill techniques due to the challenges of underwater deposition, relying primarily on sediment redeposition that does not provide structural support.

Hydraulic Backfilling Automation

Hydraulic backfilling automation in cut and fill mining enhances ground support by precisely controlling slurry deposition, reducing manual labor and increasing safety, whereas deep sea mining relies on remotely operated vehicles for sediment extraction in complex underwater environments with minimal backfilling options. Advanced sensor integration and real-time monitoring systems optimize hydraulic backfilling efficiency in terrestrial mines, contrasting the logistical challenges and environmental considerations faced in deep sea mining operations.

Paste Fill Geomechanics

Cut and fill mining relies on paste fill geomechanics to stabilize underground voids by injecting a mixture of tailings and binder, improving ground support and reducing surface subsidence. In contrast, deep sea mining involves extracting polymetallic nodules from the ocean floor, where paste fill techniques are less applicable due to the unique geomechanical challenges of underwater sediment stabilization.

Cut-and-Fill Blending Algorithms

Cut-and-fill blending algorithms optimize ore extraction and waste management by selectively filling mined-out voids in underground mining, enhancing resource recovery and ground stability. Deep sea mining, contrastingly, involves remotely operated extraction on the ocean floor, where blending algorithms are less applicable due to unique environmental constraints and heterogeneous mineral deposits.

In-Situ Leaching Subsea

Cut and fill mining involves excavating ore in horizontal slices and backfilling the voids to maintain ground stability, suitable for stable terrestrial deposits, while Deep Sea Mining targets polymetallic nodules, sulfides, and crusts on the ocean floor using remote-operated vehicles to minimize environmental disruption. In-situ leaching subsea represents an innovative technique in ocean mining by injecting chemical solutions directly into mineral deposits beneath the seabed to dissolve and extract metals such as copper and uranium, reducing physical excavation and ecological impact compared to traditional deep-sea mining methods.

Polymetallic Nodule Extraction

Cut and fill mining involves removing ore and filling voids within terrestrial mine sites, offering controlled extraction but limited scalability, while deep sea mining targets polymetallic nodules on the ocean floor, providing access to high concentrations of manganese, nickel, cobalt, and copper in vast deposits at depths of 4,000 to 6,000 meters. Polymetallic nodule extraction presents significant environmental challenges, such as habitat disruption and sediment plumes, yet it remains a promising source of critical metals essential for battery technologies and renewable energy applications.

Mining Support Vessels (MSVs)

Mining Support Vessels (MSVs) play a crucial role in both Cut and Fill mining and Deep Sea Mining by providing essential logistics, equipment transport, and operational support. MSVs equipped with advanced dynamic positioning systems enable precise deployment of submersible mining tools in Deep Sea Mining, while in Cut and Fill operations, they facilitate the transport of excavated materials and supply of backfill materials, enhancing overall efficiency and safety.

Environmental Sediment Plume Control

Cut and fill mining minimizes environmental sediment plumes by confining excavation within controlled pit areas, reducing turbidity and sediment dispersion. In contrast, deep-sea mining generates widespread sediment plumes that disrupt marine ecosystems, requiring advanced plume control technologies to mitigate ecological impact.

Remote Operated Mining Vehicles (ROVs)

Cut and fill mining employs Remote Operated Mining Vehicles (ROVs) to precisely excavate underground while stabilizing mine walls, optimizing material recovery in structured environments. Deep sea mining relies on advanced ROVs designed for extreme underwater conditions to extract polymetallic nodules and sulfide deposits, enabling resource acquisition from ocean floors beyond human reach.

Seafloor Massive Sulphide (SMS) Recovery

Cut and fill mining offers precise ore extraction in terrestrial environments, but Deep Sea Mining targets Seafloor Massive Sulphide (SMS) deposits rich in copper, zinc, gold, and silver, enabling access to vast untapped resources on the ocean floor. SMS recovery through deep sea mining involves advanced remotely operated vehicles (ROVs) and hydraulic excavation techniques to minimize environmental disturbance while maximizing metal yield.

Cut and fill vs Deep sea mining Infographic

industrydif.com

industrydif.com